High-precision vertical column relieving machine

A tooth shovel, high-precision technology, applied in the field of tooth shovel, can solve the problems of small processing range, low processing efficiency, adjustment, etc., and achieve the effect of increasing the processing range, improving work efficiency, and reducing heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

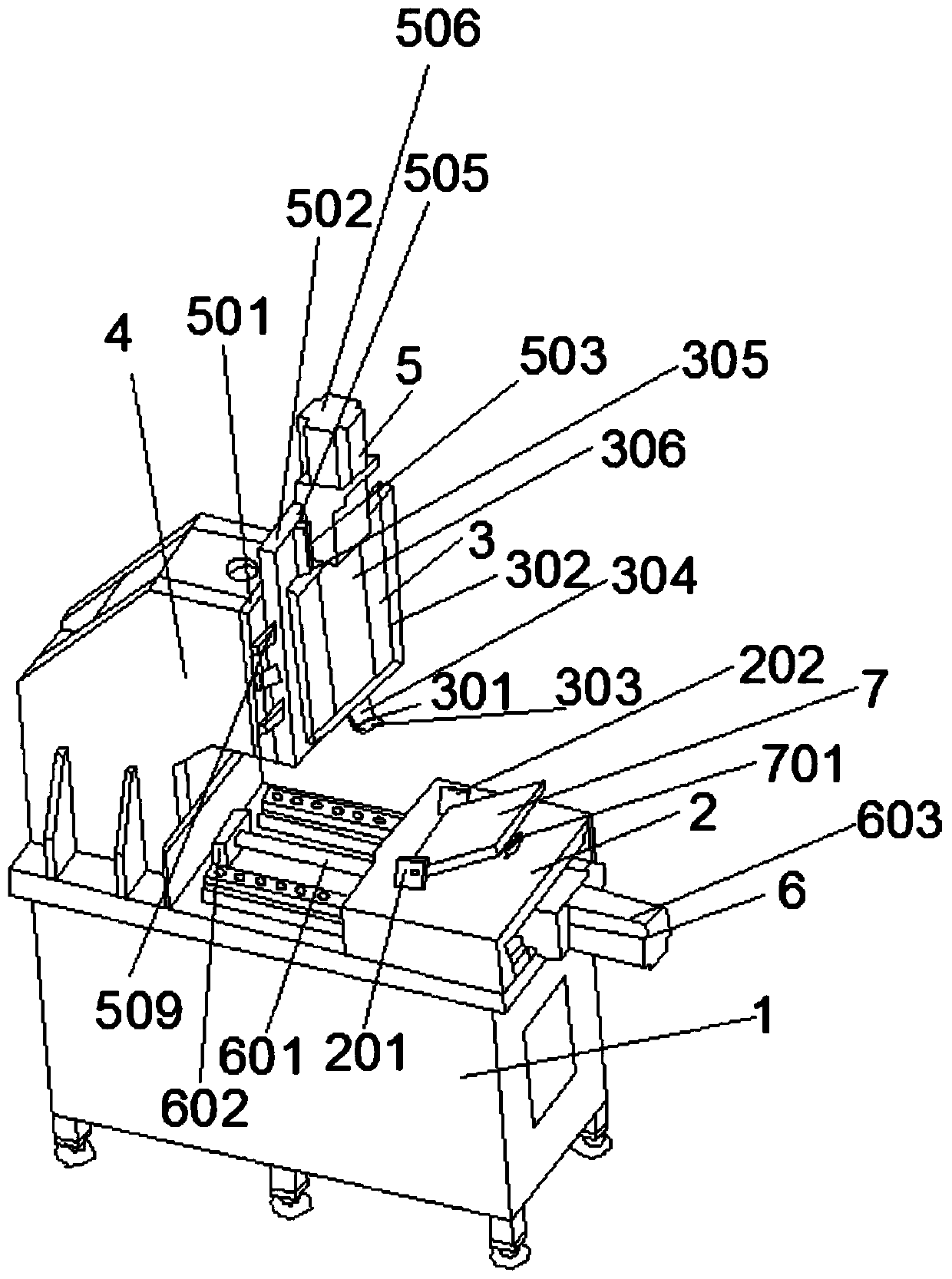

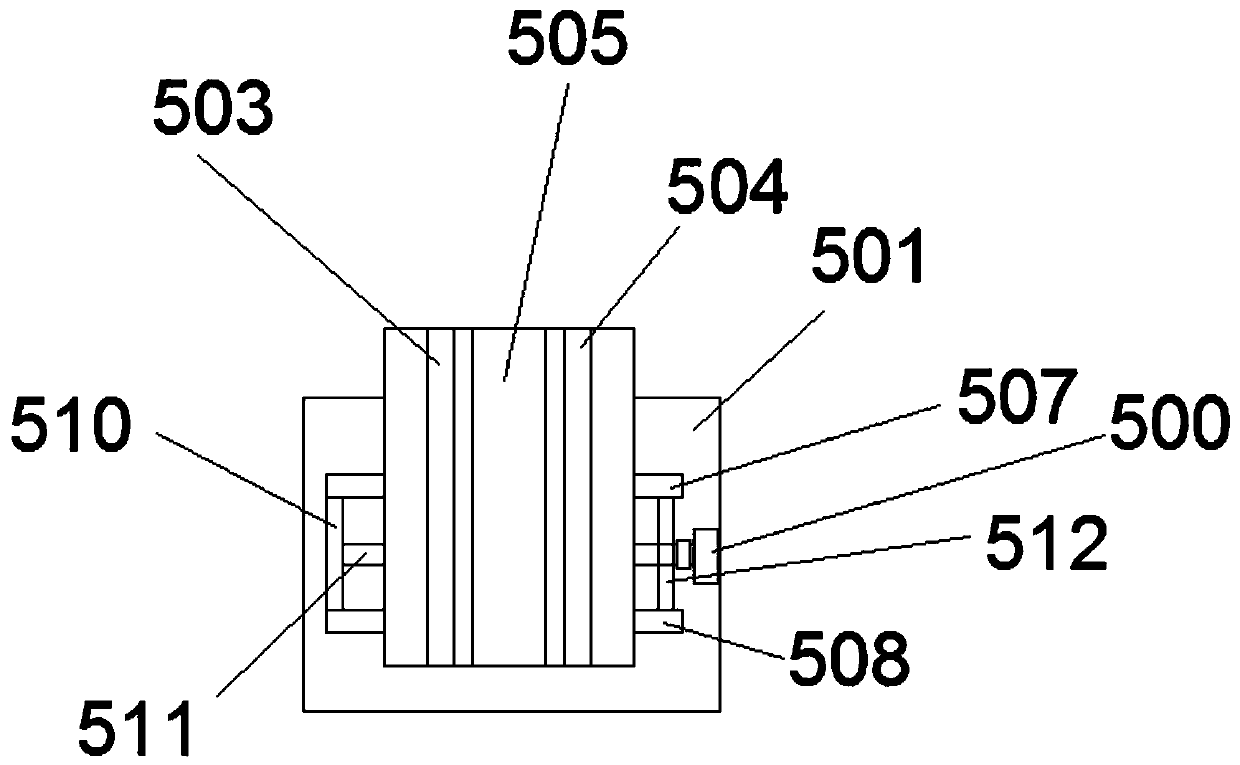

[0019] Such as Figure 1-2 As shown, this embodiment provides a high-precision column shoveling machine, including a base 1, a workbench 2, and a shoveling mechanism 3. One side of the base 1 is provided with a column 4 on which the shoveling mechanism is erected above the workbench. The column 4 is provided with a mobile device 1 that drives the shoveling mechanism 3 to move up and down and left and right, and the base is provided with a mobile device 2 6 that drives the workbench to move back and forth in the direction of the column. The shoveling mechanism 3 is provided with The shovel installation surface 301 inclined downward toward the workbench, the shoveling mechanism 3 includes a lifting seat 302 connected to the mobile device 5 and a shovel 303, the lower end of the lifting seat is provided with a knife seat connected to the shovel 304, the shovel installation surface 301 is arranged on the lower end surface of the knife seat 304, the included angle between the shove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com