A kind of superfine heat treatment method of hot work die steel

A heat treatment method and technology for hot-working die steel, applied in heat treatment equipment, manufacturing tools, quenching agents, etc., can solve the problems of slow heat transfer, steel cracking, high cost, etc., achieve finer and more uniform grain size, and accelerate cooling speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

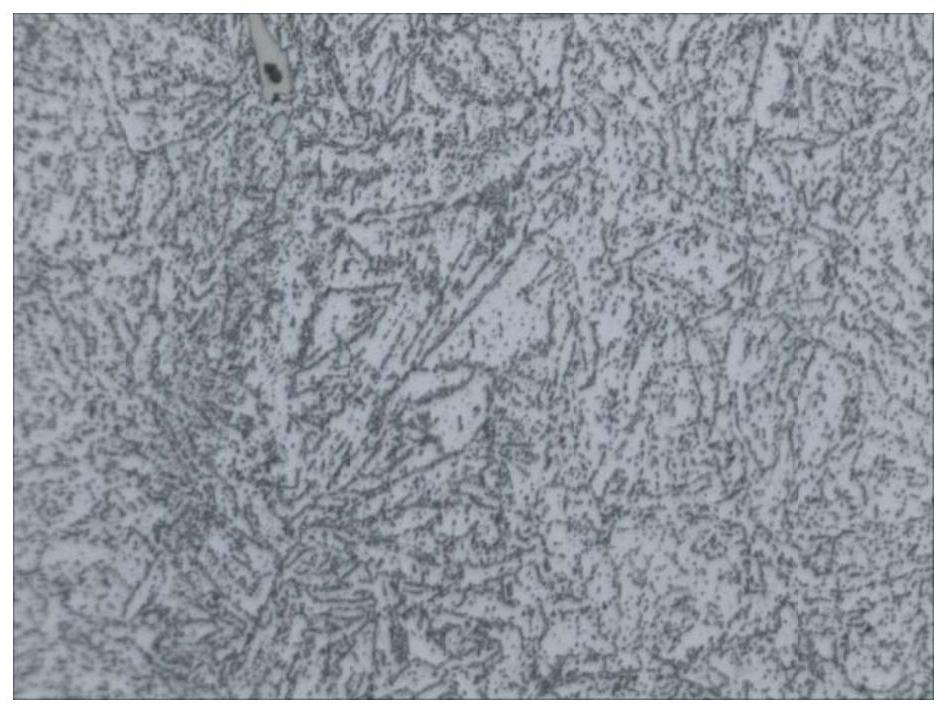

[0026] Taking H13 round steel as the processing object, the metallographic structure before the untreated H13 round steel, such as figure 1 shown. (AS15 grade 500×)

[0027] After forging, under the condition of being filled with inert gas, control the temperature at 860°C, keep it for 5 hours, then quickly cool it (cooling rate is 20°C / s) to 650°C, keep it for 6 hours; perform isothermal preheating, the preheating temperature is 660°C ;Rapid heating (heating rate: 1°C / min) to 1060°C, then keep warm for 20 minutes, then lower the temperature to below 1050°C, place in water, and cool. Next, it is finally cooled with the furnace to below 400°C.

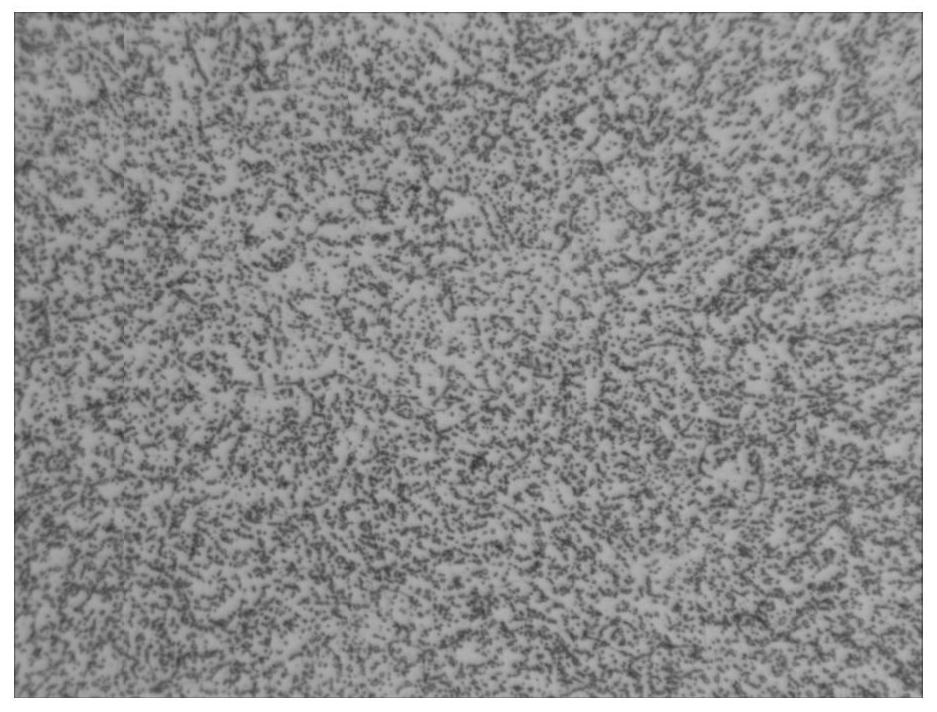

[0028] The metallographic structure of the H13 round steel processed through the above steps, such as figure 2 shown. (AS3 level 500×)

Embodiment 2

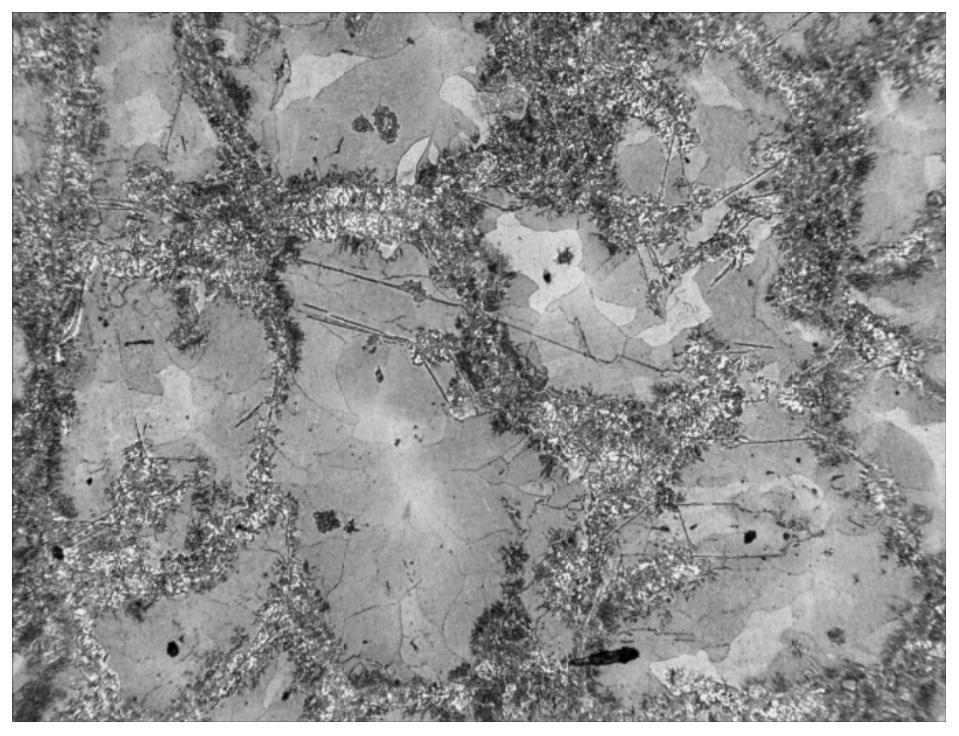

[0030] Taking the 8418 plate as the processing object, the metallographic structure of the 8418 plate before treatment, such as image 3 shown. (AS18 grade 500×)

[0031] After forging, under the condition of being filled with inert gas, first control the temperature at 880°C, keep it warm for 10 hours, then quickly cool it (cooling rate is 50°C / s) to 690°C, keep it warm for 8 hours, then carry out isothermal preheating, rapid heating (heating The speed is 2°C / min) to 1060°C and then keep warm for 60 minutes, then lower the temperature to below 1050°C, place in water, and cool.

[0032] The metallographic structure of the 8418 plate after the above steps, such as Figure 4 shown. (AS2 level 500×)

Embodiment 3

[0034] Taking 5H12 round steel as the processing object, the metallographic structure before the untreated 5H12 round steel, such as Figure 5 shown. (AS13 grade 500×)

[0035] After forging, under the condition of being filled with inert gas, firstly control the temperature at 890°C, keep it warm for 6 hours, then quickly cool it (cooling rate is 50°C / s) to 680°C, keep it warm for 7 hours, and then carry out isothermal preheating, the preheating temperature is 1010°C; rapid heating (heating rate: 2°C / min) to 1060°C, then keep warm for 30 minutes, then lower the temperature to below 1050°C, place in water, and cool.

[0036] The metallographic structure of 5H12 round steel after the above steps, such as Figure 6 shown. (AS2 level 500×)

[0037] From the test of embodiment 1~embodiment 3, can find out. The hot work die steel treated by the method has significantly finer and more uniform particles than before treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com