Multi-point floor type steel frame protection method for bridge structure adjacent to high tension line

A technology for bridge structure and high-voltage lines, which is applied in bridges, bridge construction, infrastructure engineering, etc., can solve the problems of non-relocation and construction of adjacent high-voltage lines, and achieve the effect of reducing construction costs, improving work efficiency, and speeding up construction progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

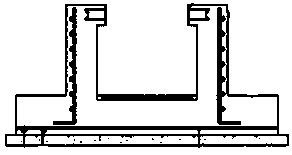

[0032] Such as figure 1 As shown, the present invention provides a method for protecting a multi-point floor-standing steel frame near a high-voltage line bridge structure, comprising steps:

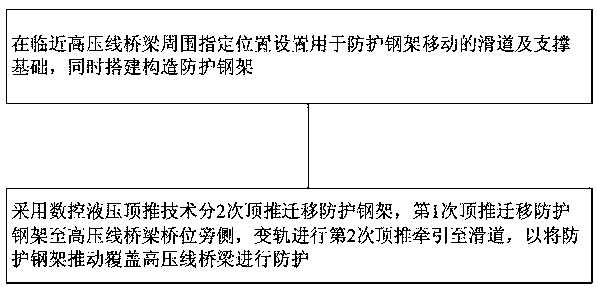

[0033] S110: Set slides and supporting foundations for protecting the movement of the steel frame at designated locations around the bridge near the high-voltage line, and build a structural protective steel frame at the same time.

[0034] The steps for constructing the skid and supporting foundation include:

[0035] Construction setting out and foundation bearing capacity testing;

[0036] When the bearing capacity of the foundation is tested and passed, the concrete for the cushion layer is poured, the steel skeleton is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com