Ultrasonic phased array full-automatic detection method for blades and blade roots of nuclear power station low-pressure cylinder shrinkage-fit rotor steam turbine

A steam turbine blade and ultrasonic phased array technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and measurement devices, etc. and other problems, to achieve the effect of reliable detection of data, guarantee of accuracy, and guarantee of coding records

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

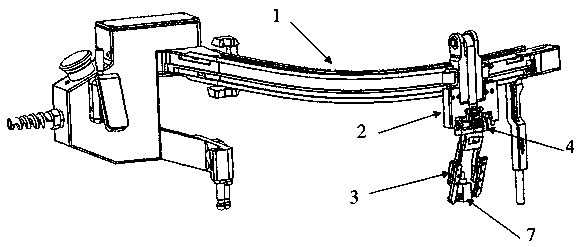

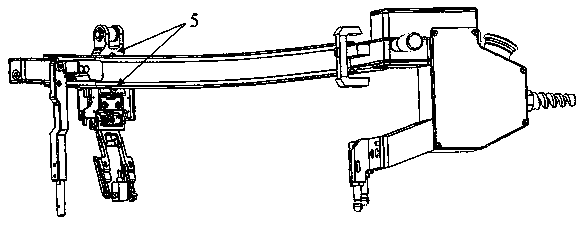

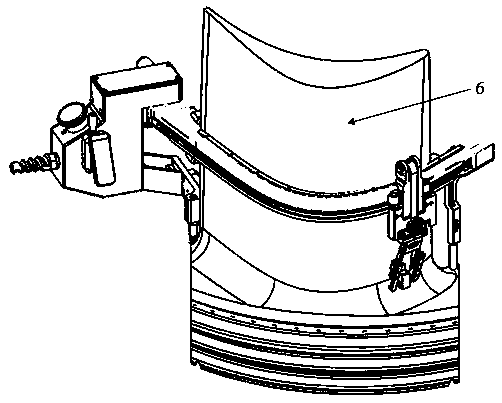

[0042] The present invention determines the setting and walking area of the phased array probe according to different detection areas, specifically: setting the phased array probe on the outer arc side of the blade root to detect the inner arc side of the blade root, placing the phased array probe Set on the inner arc side of the blade root to detect the outer arc side of the blade root, and install the phased array probe on the outer arc side platform on the air outlet side of the blade root to detect the inner arc and outer arc on the air outlet side of the blade root On the arc side, the phased array probe is arranged on the outer arc side platform on the inlet side of the blade root to detect the inner arc and outer arc side on the inlet side of the blade root.

[0043] The equipment used in the detection may include a scanner, a phased array probe, an ultrasonic phased array detector, a drive control device, a water pump and a water tank, and the phased array probe may b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com