PLC architecture for mine communication control system and mine communication control system

A technology of communication control and controller, which is applied in general control systems, program control in sequence/logic controllers, control/regulation systems, etc. It can solve the problems of poor EMC protection performance of hardware, cumbersome configuration, and difficulty in product function software development major issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

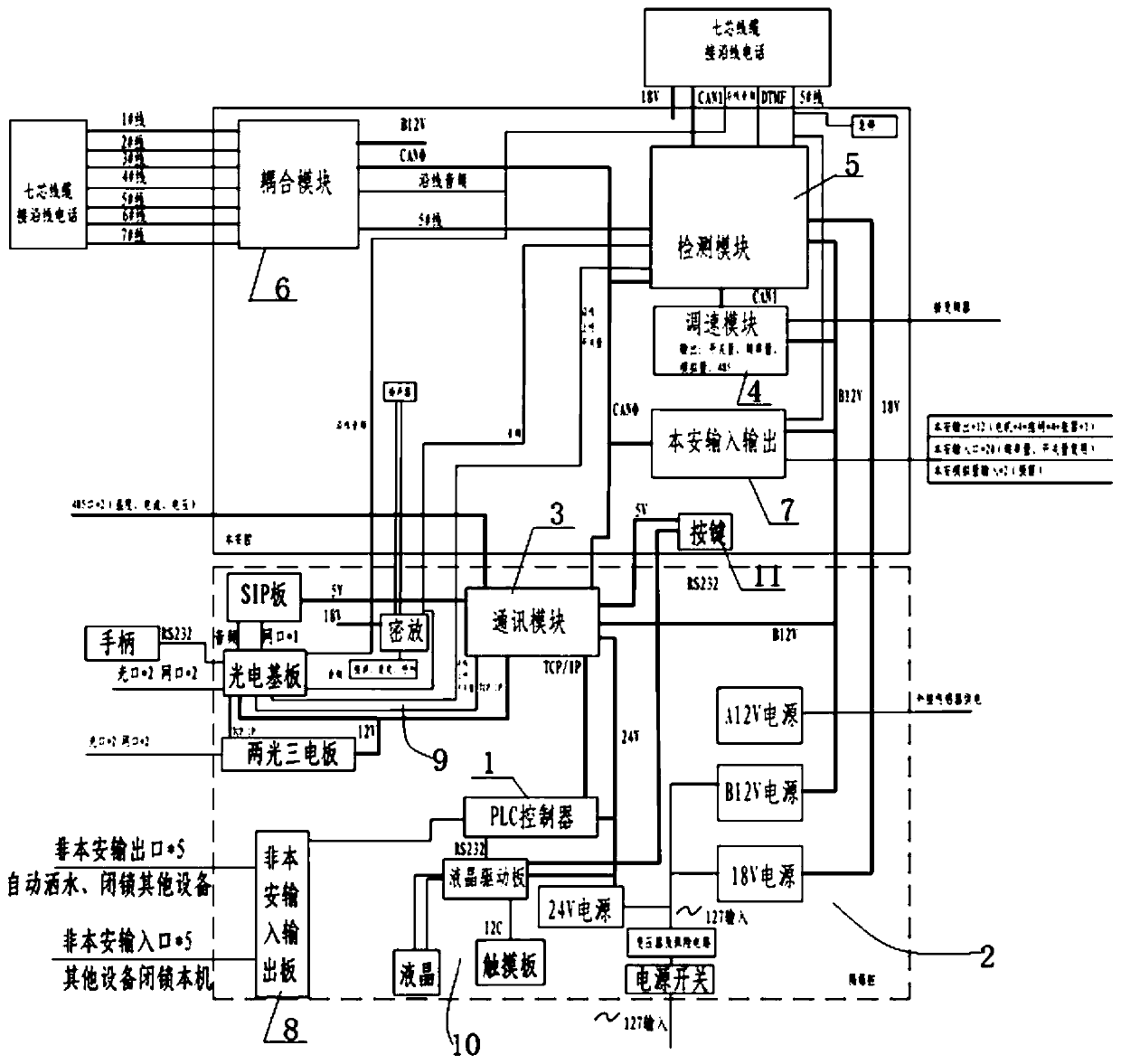

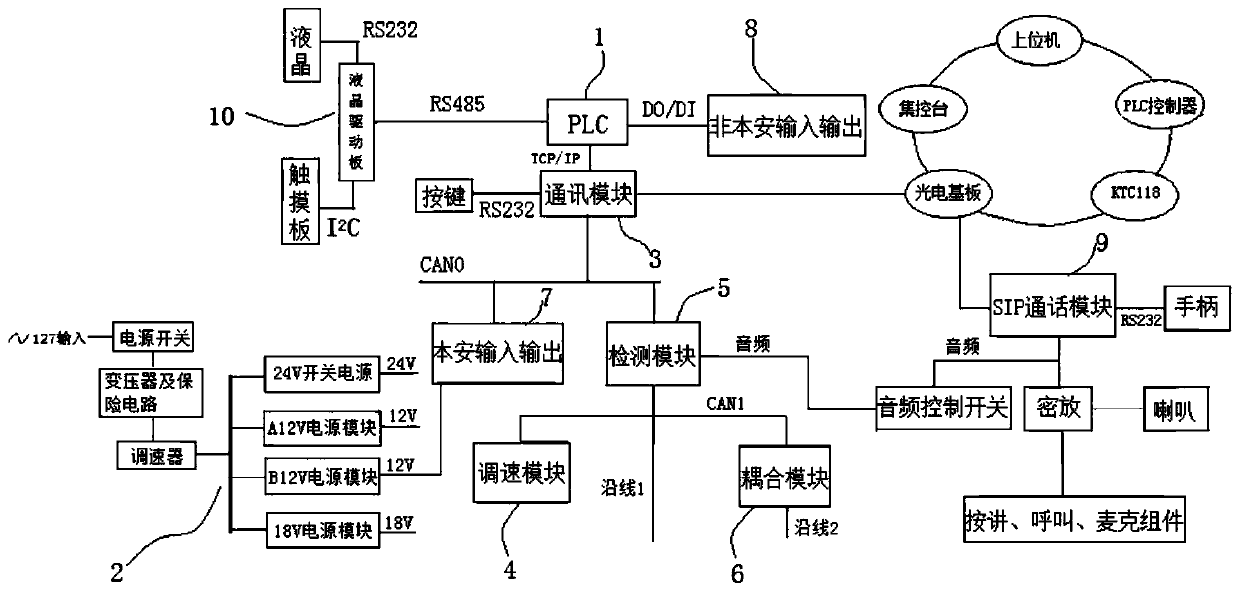

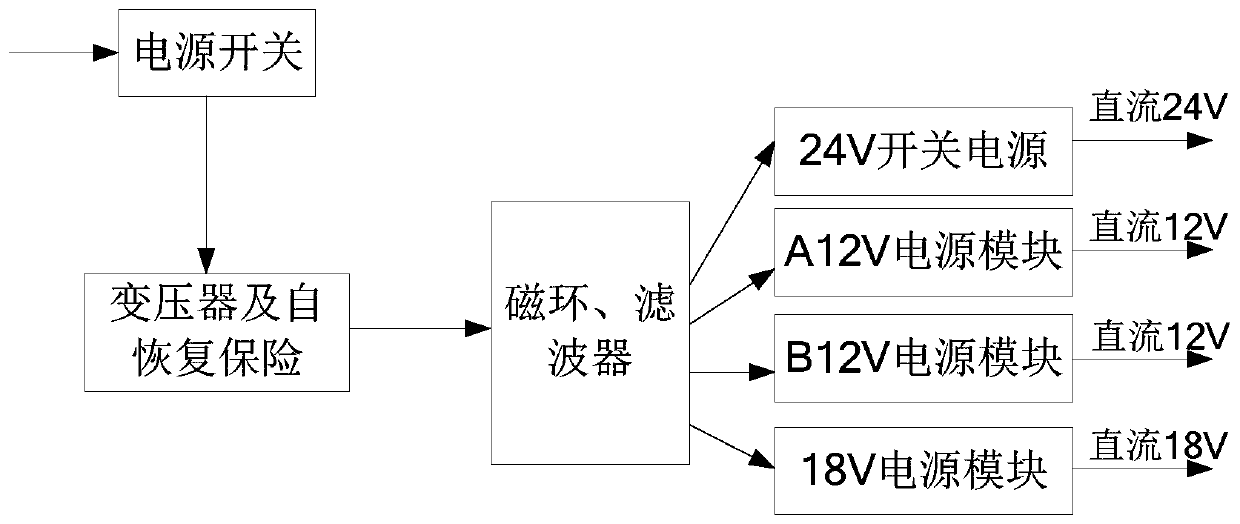

[0049] figure 1 It is a schematic diagram of the overall structure of the PLC controller architecture of the mine communication control system involved in the embodiment. Such as figure 1 As shown, the PLC controller architecture includes a PLC controller 1, a power supply module 2, a communication module 3, a speed regulation module 4, a detection module 5, a coupling module 6, an intrinsically safe input and output module 7, and a non-intrinsically safe input and output module 8 , voice call module 9 and liquid crystal display module 10. figure 2 It is a schematic diagram of the overall relational connection of the PLC controller architecture. Such as figure 2 As shown, the PLC controller 1 is connected to the liquid crystal display module 10 through the RS485 serial port, the input / export of the PLC controller 1 is connected to the non-intrinsically safe input and output module 8, and the communication interface of the PLC controller 1 is connected to the communication...

Embodiment 2

[0086] This embodiment provides a mining communication control system, which includes a PLC controller architecture, a centralized control console, and a sensor module, and the PLC controller architecture is connected to the centralized console and the sensor module respectively to realize the operation It can also control the start, stop, lock control, fault monitoring, intelligent speed regulation, high temperature automatic watering function of the emulsification pump and the belt conveyor. etc.; it can be connected with KTC118 and KTC2 along the line equipment to realize the status detection, press-to-talk, and call functions along the line; remote dial-up calls are made with other equipment through the network, and the sensor module is used to detect the start and stop status of the equipment along the line. The belt speed, smoke, longitudinal tear, running deviation, coal pile, motor oil temperature, shaft temperature and other working conditions are detected, and the equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com