Display panel

A technology for display panels and substrates, applied in semiconductor devices, electrical components, photovoltaic power generation, etc., can solve the problems of metal wiring breakage in the bending area, reducing the reliability of the display panel, uncontrollable bending radius, etc. ratio, the effect of reducing the border width, and reducing the bend radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

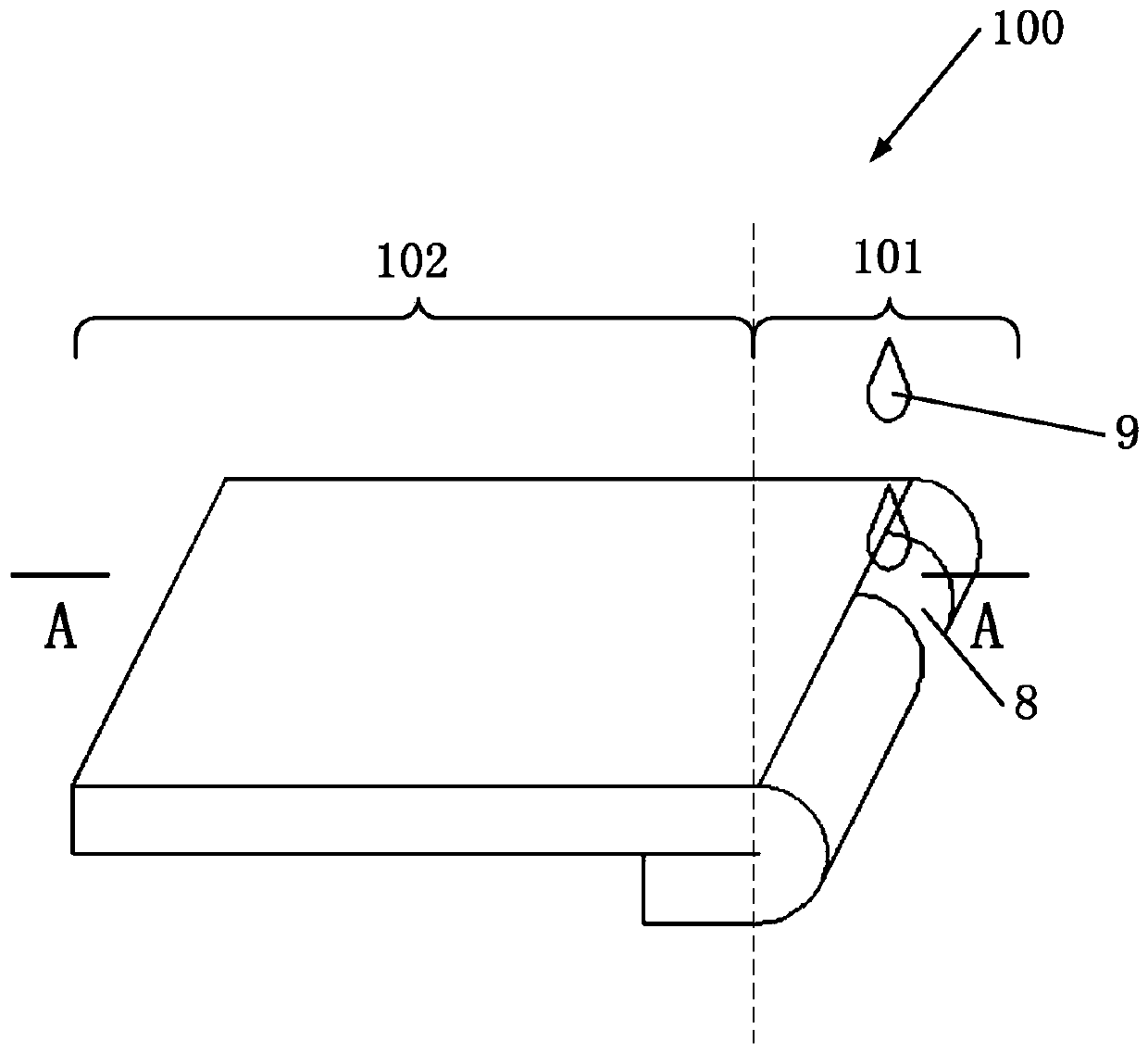

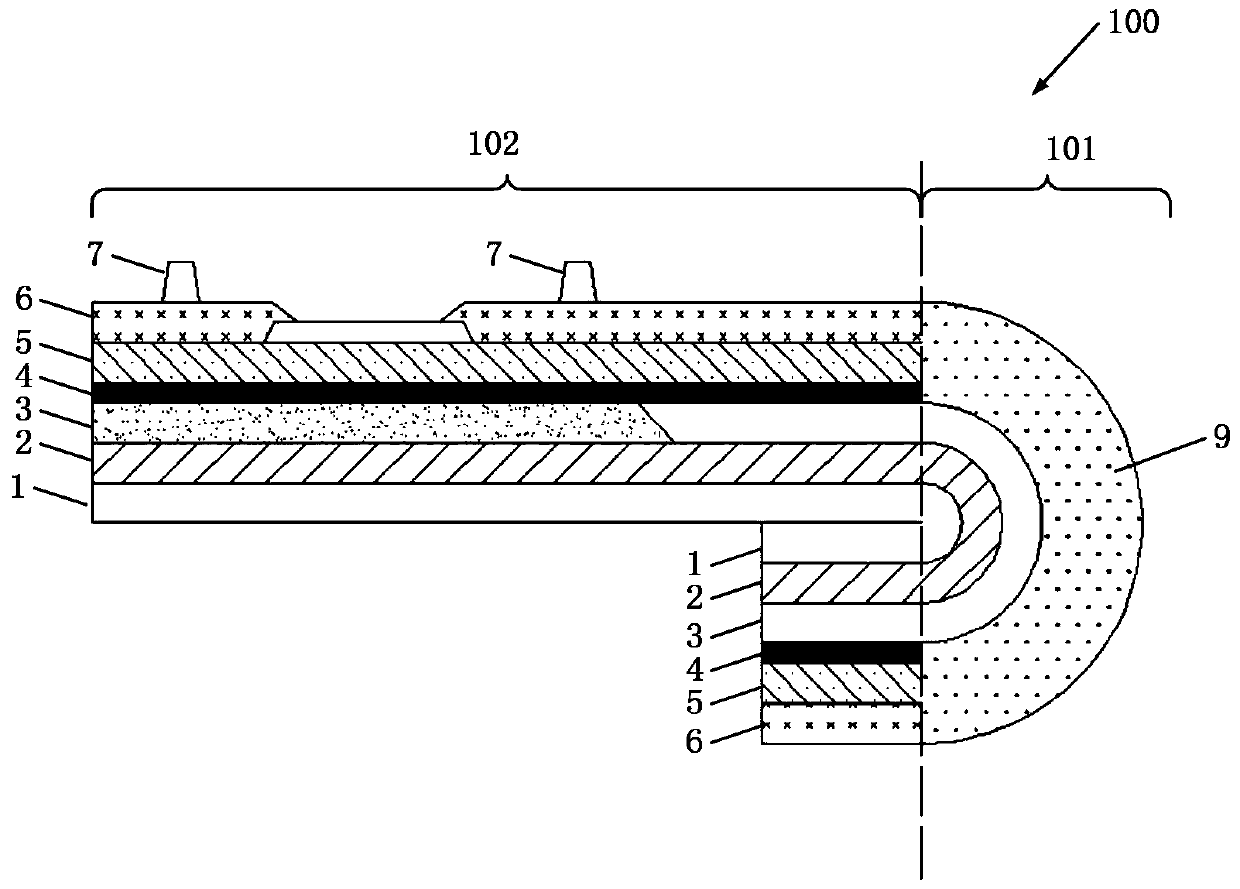

[0042] like figure 1 , figure 2 As shown, a display panel 100 is defined with a bending area 101 and a non-bending area 102, which includes: a substrate 1, a semiconductor device layer 2, an insulating layer 3, a source and drain layer 4, a flat layer 5, and a pixel definition layer 6 and support column 7.

[0043] Wherein the semiconductor device layer 2 is disposed on the substrate 1 . Specifically, the semiconductor device layer 2 includes: an active layer, a gate insulating layer, and a gate layer. Wherein the active layer is disposed on the substrate; the gate insulating layer is disposed on the active layer; the gate layer is disposed on the gate insulating layer; details will not be repeated here.

[0044] The insulating layer 3 is disposed on the semiconductor device layer 2; specifically, the insulating layer 3 is disposed on the gate layer. The insulating layer 3 mainly plays an insulating role, preventing the source-drain layer 4 from directly contacting the ga...

Embodiment 2

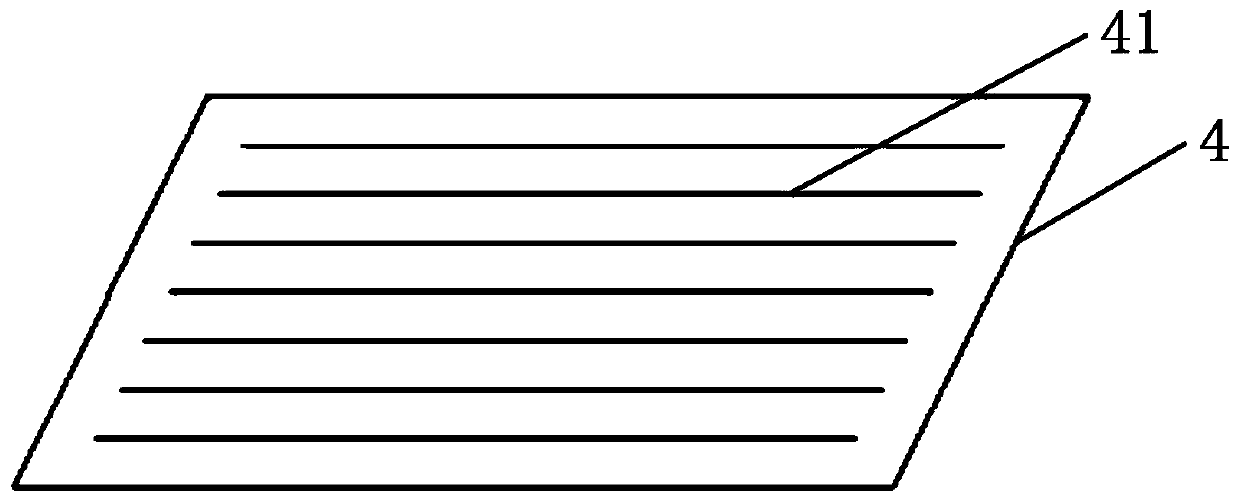

[0052] like Figure 4 , Figure 5 As shown, the display panel 100 in this embodiment further includes a backing plate 10 , and the backing plate 10 is disposed on a side of the substrate 1 away from the source-drain layer 4 . In this embodiment, the shape of the contact side surface between the backing plate 10 and the substrate 1 after bending is rectangular. Wherein the groove 8 can go through the pixel definition layer 6, the planar layer 5 to the source and drain layer 4, and then fill the groove 8 with conductive material, thereby connecting the metal wiring 41, so that The metal wiring 41 in the bending area 101 does not need to consider the stress balance problem, thereby reducing the bending radius, reducing the frame width, increasing the screen-to-body ratio, and finally bringing better visual experience to customers.

[0053] like Image 6 , Figure 7 As shown, more preferably, the backing plate 10 is provided with conductive bridges 11 at intervals correspondin...

Embodiment 3

[0056] like Figure 8 , Figure 9 As shown, the difference between this embodiment and Embodiment 2 lies in that: the display panel 100 further includes a backing plate 10 , and the backing plate 10 is disposed on a side of the substrate 1 away from the source-drain layer 4 . In this embodiment, the shape of the contact side surface of the backing plate 10 and the substrate 1 after bending is arc-shaped. Wherein the groove 8 can go through the pixel definition layer 6, the planar layer 5 to the source and drain layer 4, and then fill the groove 8 with conductive material, thereby connecting the metal wiring 41, so that The metal wiring 41 in the bending area 101 does not need to consider the stress balance problem, thereby reducing the bending radius, reducing the frame width, increasing the screen-to-body ratio, and finally bringing better visual experience to customers.

[0057] like Figure 10 As shown, more preferably, wherein the backing plate 10 is provided with condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com