A battery formation and acid pumping control device and acid pumping process

A battery formation and control device technology, applied to secondary batteries, lead-acid batteries, battery pack components, etc., can solve problems affecting battery consistency and service life, low production efficiency, high labor costs, etc., to achieve effective control of pumping Acid quality, reduced labor costs, and improved cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

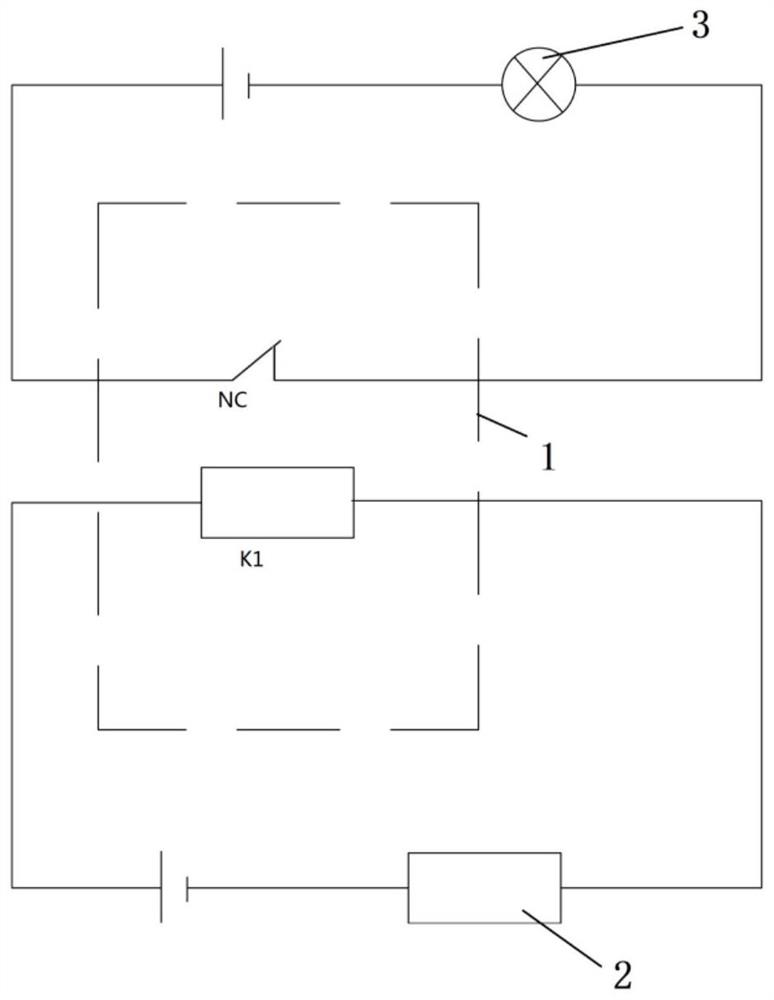

[0040] A kind of battery into acid pumping control device, such as figure 1 As shown, it includes a controller 1, an electrolyte detection part 2 and an indicator light 3; the electrolyte detection part 2 is connected to the acid suction pipe, and the electrolyte detection part 2 is used to detect whether the free electrolyte in the battery has been pumped clean. The detection part 2 is connected with the controller 1, and the controller 1 controls the switch of the indicator light 3 according to the acid pumping situation.

[0041] The acid pumping control device of the present invention can accurately indicate the acid pumping status of the battery formation, facilitate the operator to judge according to whether the indicator light 3 is on or not, can effectively control the acid pumping quality, and can save the acid checking process in the AGM battery formation, Thereby reducing labor costs in battery manufacturing.

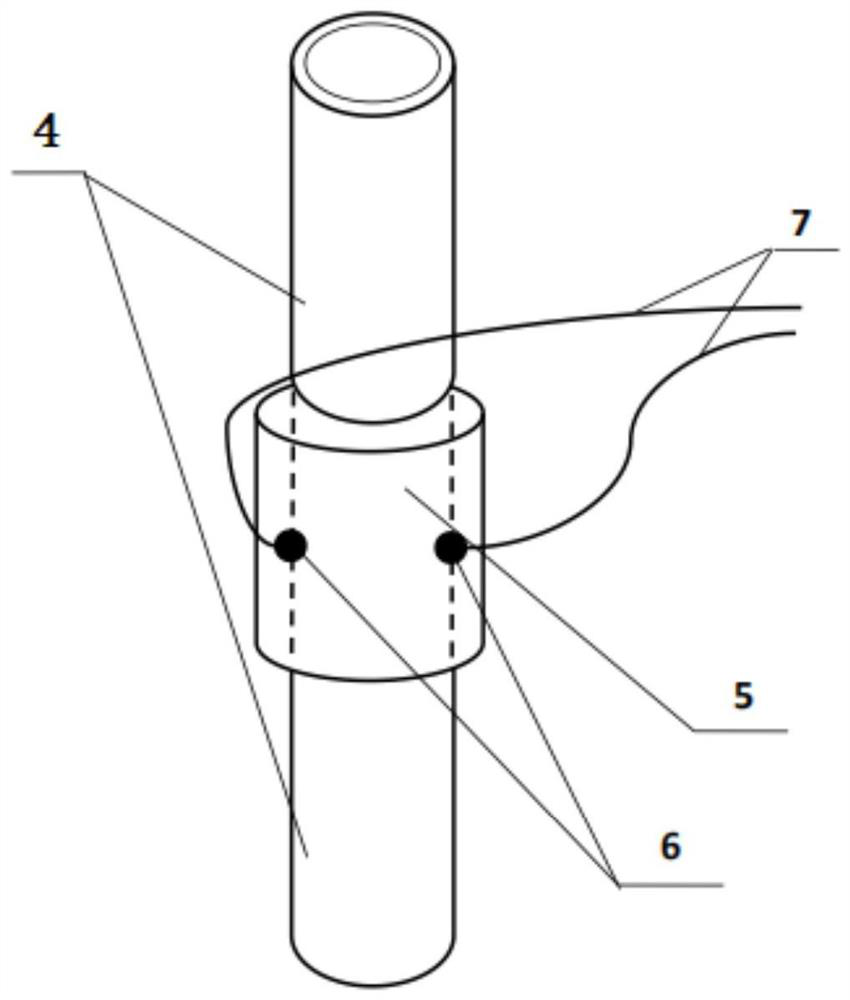

[0042] Such as image 3 As shown, the electrolyte det...

Deformed example 1

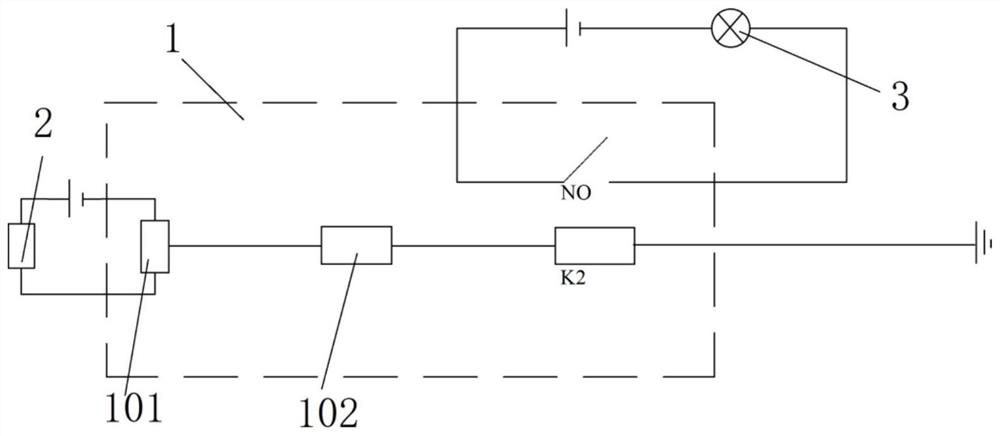

[0050] A modified example of embodiment 1, such as figure 2 As shown, the controller 1 includes a detection unit 101, a control unit 102 and a relay K2; the relay K2 includes a coil of the relay K2 and a normally open contact NO; other components are the same as those in the embodiment.

[0051] The detection unit 101 is connected to the electrolyte detection part 2, and is used to detect whether the circuit of the electrolyte detection part 2 is turned on or off; the control unit 102 controls the relay K2 according to the change of the signal detected by the detection unit 101, thereby controlling the lighting of the indicator light 3 or off. Only when the signal detected by the detection unit 101 changes from the on signal to the off signal, the control unit 102 controls the indicator light 3 to light up according to the change signal from on to off, and the other signal indicator lights 3 are not on. Bright. The controller 1 of modification 1 makes the indicator light 3 ...

Embodiment 2

[0056] A kind of battery formation into acid extraction process, adopts the battery formation into acid extraction control device in embodiment 1, comprises the following steps:

[0057] Step 1. Connect the acid pumping tube adapter to the acid pumping tube;

[0058] Step 2. Insert the acid pumping tube into the battery liquid injection port;

[0059] Step 3. Carry out acid pumping;

[0060] Step 4. The indicator light 3 lights up, the acid extraction is completed, take out the acid extraction tube.

[0061] The acid pumping process of the present invention can accurately indicate the acid pumping status of the battery formation, and the operator can judge according to whether the indicator light 3 is on or not, which can effectively control the acid pumping quality, accurately control the saturation of the electrolyte in the battery, and solve the problem of AGM battery The unbalanced electrolyte saturation problem effectively improves the consistency of the battery and pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com