Differential pressure sensor filter and use thereof

A filter and sensor technology, applied in the field of differential pressure sensor filters, can solve problems such as room pressure out of control, filter clogging, inaccurate detection of differential pressure sensors, etc., and achieve the effect of improving the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0040] In a first exemplary embodiment of the present disclosure, a differential pressure sensor filter is provided.

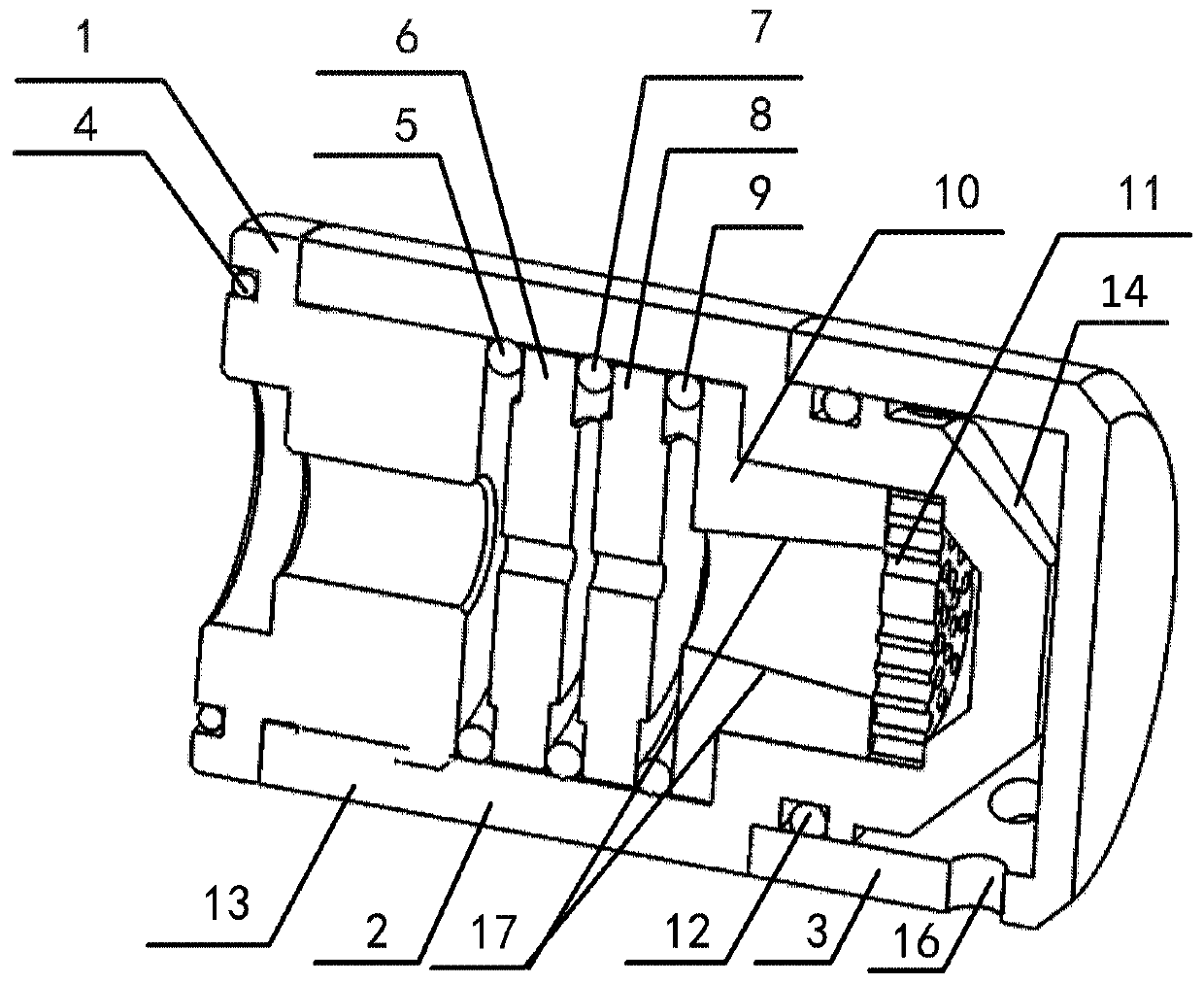

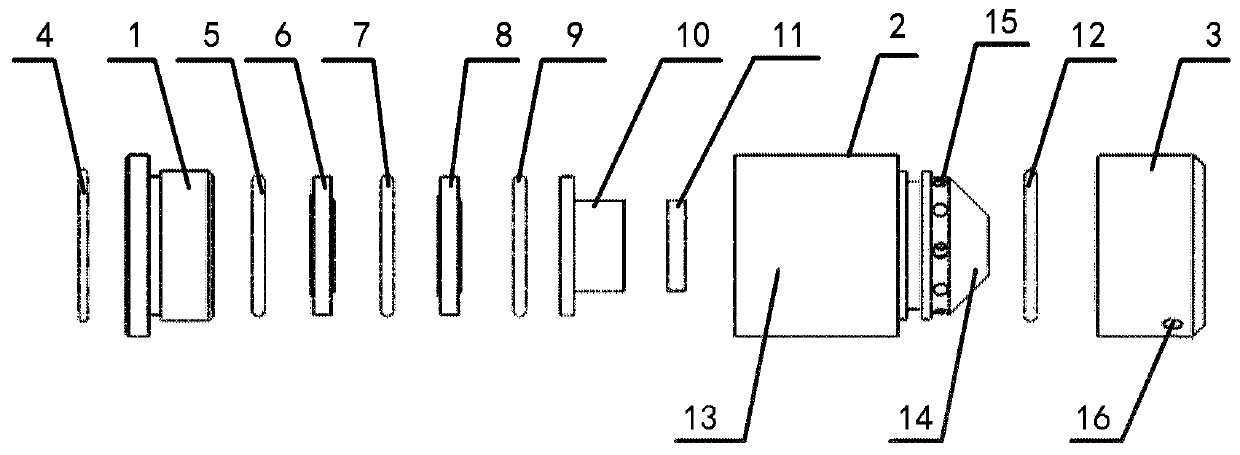

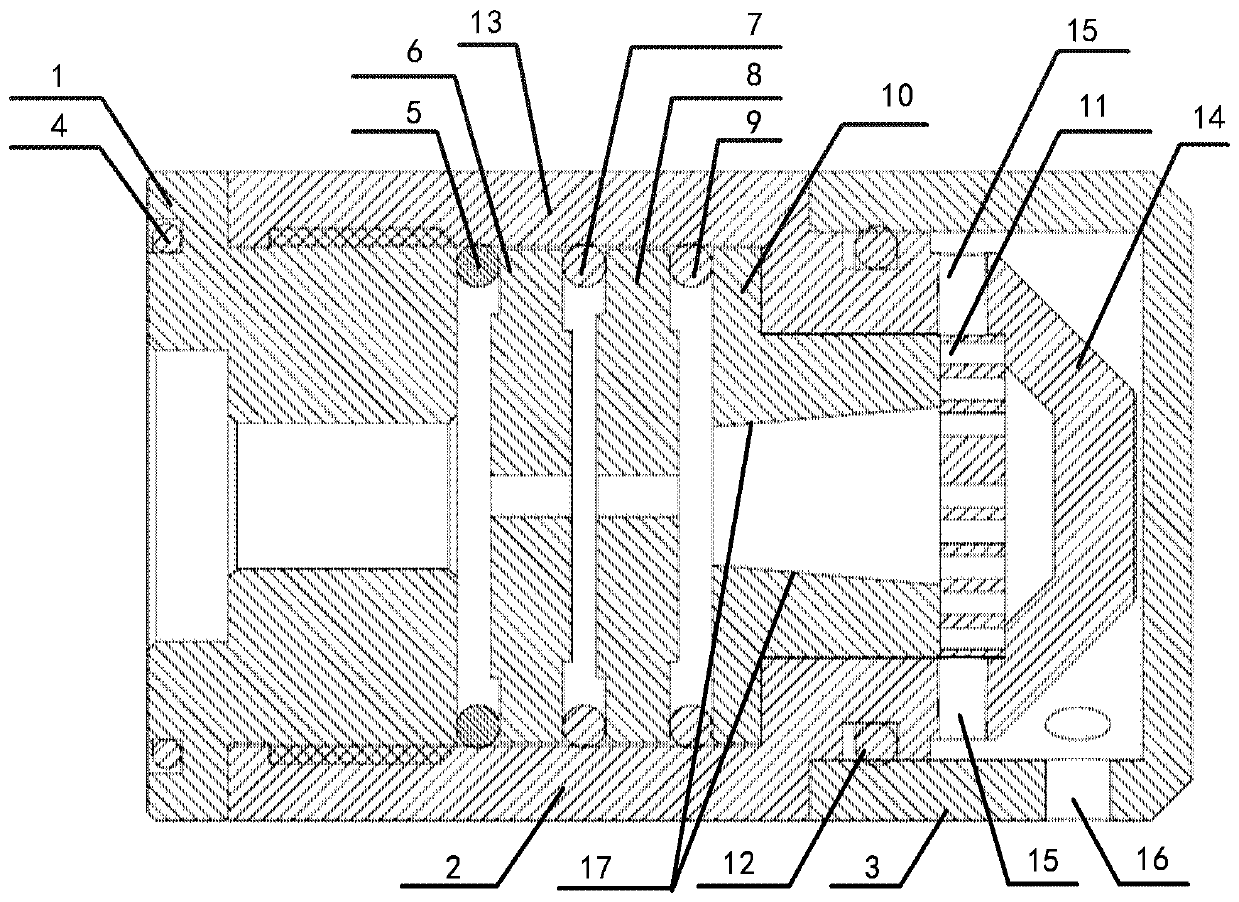

[0041] figure 1 It is a three-dimensional structural schematic diagram of a differential pressure sensor filter according to an embodiment of the present disclosure. figure 2 For such figure 1 An exploded view of the structure of the differential pressure sensor filter shown. image 3 For such figure 1 Cutaway view of differential pressure sensor filter shown.

[0042] Among them, in the description of the full text, "top" is along the figure 2 / image 3 In the right direction, "bottom" is along the figure 2 / image 3 Orientation on the left side. The description of the top and bottom is relative to the drawings. In the actual structure, when the position of the overall structure is shifted or reversed, the corresponding description direction may change.

[0043] refer to Figure 1-Figure 3As shown, the differential pressure sensor filter of the...

no. 2 example

[0063] In a second exemplary embodiment of the present disclosure, an application of the differential pressure sensor filter in a biosafety laboratory, especially in a chemical shower room of a biosafety laboratory is provided. Of course, it can also be applied to isolate the pressure port of the differential pressure sensor in other humid environments. In addition, it is also suitable for application scenarios that prevent the leakage of aerosols such as viruses and bacteria.

[0064] In the chemical shower room, based on the connection between the differential pressure sensor interface inside the differential pressure sensor filter and the differential pressure sensor, when the differential pressure test is performed, due to the setting of the water retaining cover and the water vapor condensation net, the water vapor is blocked and large Part of the water vapor is effectively exported. After filtering, the gas that enters the connecting pipe of the differential pressure sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com