Self-cleaned solar cell assembly with high conversion rate

A technology of solar cells and solar cells, applied in electrical components, circuits, photovoltaic power generation, etc., can solve problems such as poor cleaning effect, low photoelectric conversion efficiency, and short service life, achieve dust and hailproof capabilities, and improve photoelectric conversion Efficiency and reduction in installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

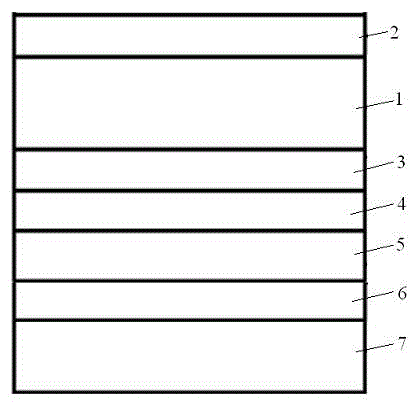

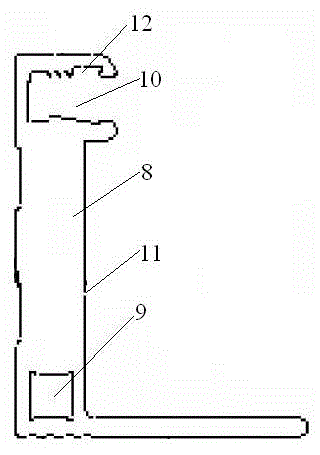

[0016] Example 1: like figure 1 and 2 As shown, a self-cleaning solar cell module with high conversion rate, including tempered glass 1, EVA film 3, anti-reflection film 4, monocrystalline silicon solar cells 5, EVA film 6, back plate 7, aluminum alloy The frame 8 and the DC junction box, the tempered glass 1, the EVA film 3, the anti-reflection film 4, the monocrystalline silicon solar cell 5, the EVA film 6 and the back plate 7 are sequentially laminated to form a component laminate. The aluminum alloy frame and silica gel seal and package the component laminate, and the monocrystalline silicon solar cell 5 is electrically connected to the DC junction box after being welded and connected to the bus bar, and the solar cell module is generated through the DC junction box. The electrical energy is output to the external system, and then the electrical energy is output to the user or stored for reuse through components such as wires, controllers, inverters or batteries. The ...

Embodiment 2

[0017] Example 2: As an improvement of the present invention, the aluminum alloy back plate adopts 5052 aluminum alloy plate as the substrate, and an anodized film of 15-20um is electroplated on both sides of the substrate. This kind of aluminum alloy back plate has good corrosion resistance , the corrosion effect on the back plate after being exposed to the air for 25 years on one side is basically negligible, and because its thermal conductivity (144w / (m.k)) is much larger than the heat conduction system of the traditional TPT back plate, the battery assembly can be The heat is exported more effectively, the temperature of the solar cell module is reduced, the efficiency of the module is improved, and the service life requirement of the module is also met. The rest of the structures and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0018] Example 3: As an improvement of the present invention, the content of iron in the raw materials for preparing the tempered glass 1 is 80--120ppm. The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com