Positioning device of fork ear type thin-wall part

A technology of positioning device and thin-walled parts, which is applied in the direction of positioning device, metal processing mechanical parts, clamping, etc., can solve the problems of difficult processing of fork lug thin-walled parts, and achieves the improvement of processing efficiency and processing accuracy, as well as improving processing efficiency. , to avoid the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

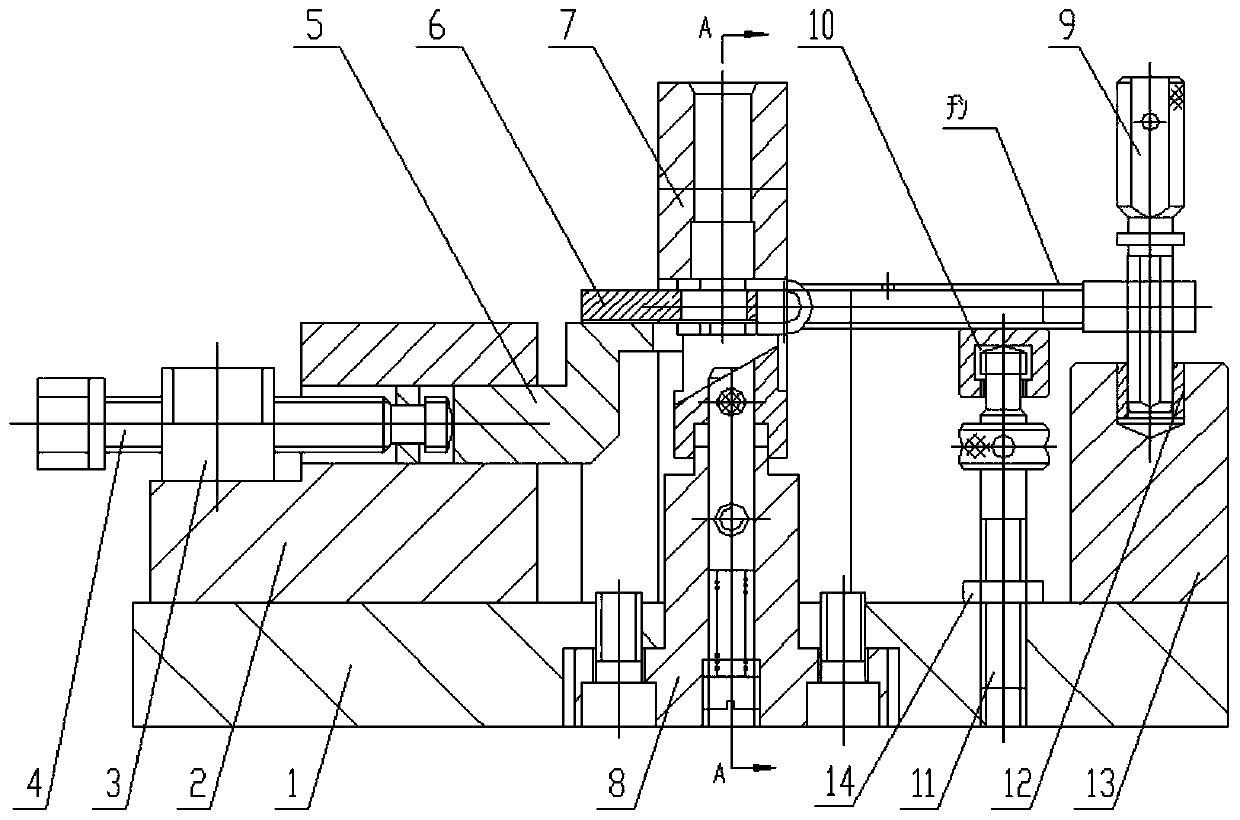

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

[0038] refer to Figure 2-8 , a positioning device for fork ear type thin-walled parts, including a base plate 1, and a guide block 2, a positioning seat 6, a base 13 and a guide template 7 arranged on the base plate, the guide block 2 and the base 13 are located on the base plate 1 The positioning seat 6 is located between the guide block 2 and the base 13 at both ends.

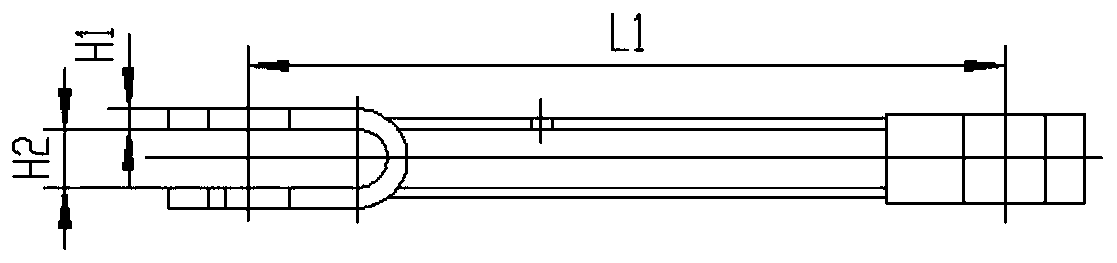

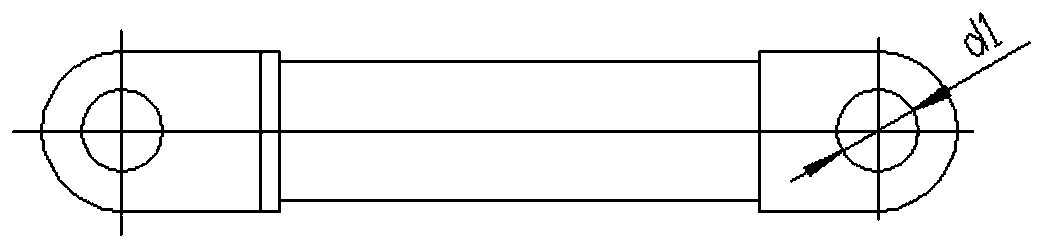

[0039] The positioning seat 6 is a U-shaped structure, including two vertical support arms and a positioning arm horizontally arranged on the top of the two support arms. The U-shaped groove is clamped on the positioning wall, and the other end of the fork-shaped thin-walled part is fixedly arranged on the top of the base 13, and the positioning wall and the base can make the fork-shaped thin-walled part in a horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com