A kind of preparation method of high swimming power emulsion

A technology for penetrating power and emulsion, which is applied in the field of preparation of emulsion with high penetrating power, can solve problems such as difficulty, reducing the thickness of the paint film of the outer panel, complexity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

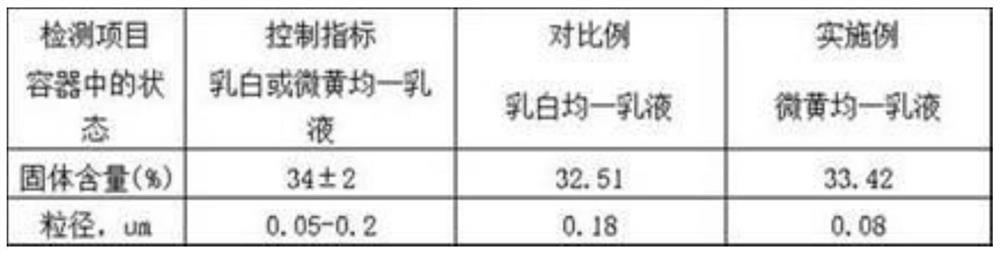

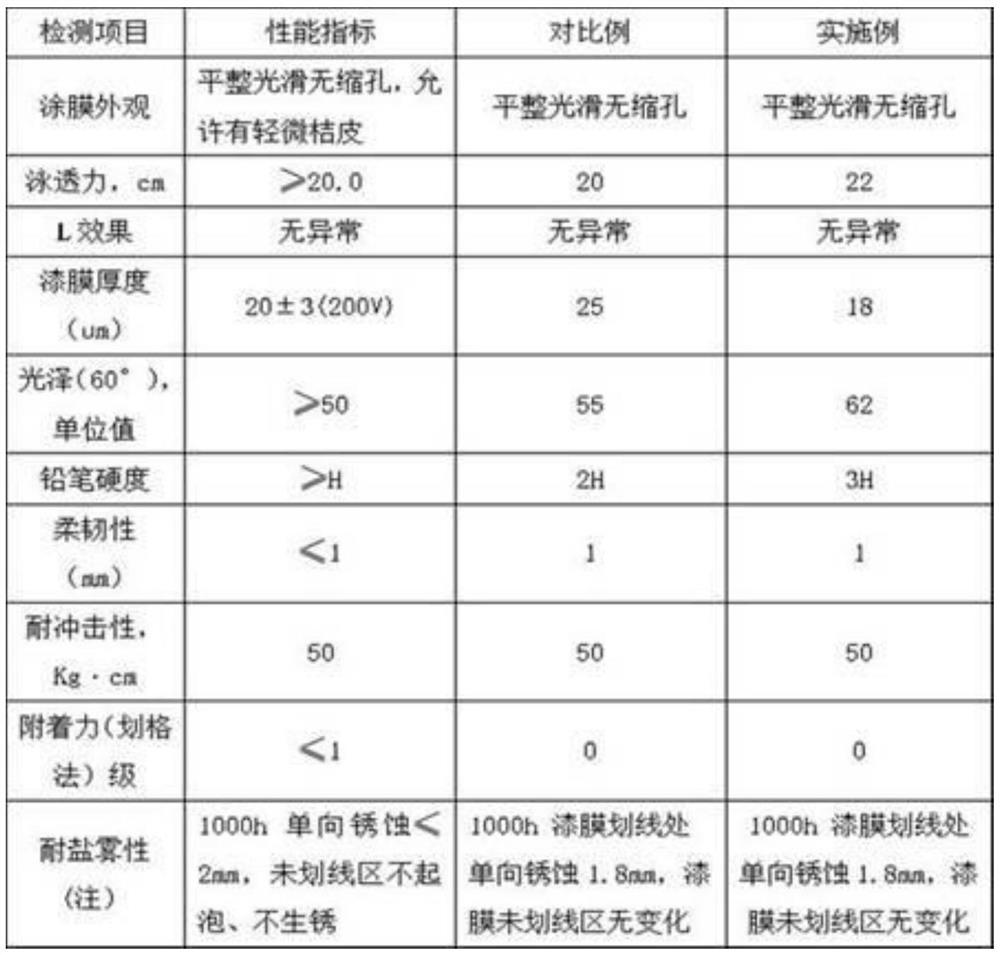

Examples

Embodiment

[0031] 1. Preparation of crosslinking agent:

[0032] S1. Put 7.6% methyl ethyl ketone and 10.8% trimethylol propane into the dropping tank, turn on the stirring, and raise the temperature of the dropping tank to 65°C (not to exceed 75°C), so that the trimethylol propane is dissolved in the methyl ethyl ketone , prepared into a mixed solution and kept warm at 50-75°C for use;

[0033] S2. Add 43.5% toluene diisocyanate, 5% methyl ethyl ketone, and 0.02% dibutyltin dilaurate to the reaction kettle, stir under nitrogen atmosphere, and heat up to 45°C; then slowly add the mixed solution obtained in S1 dropwise at a uniform speed, and react The temperature of the kettle is controlled at 55-60 ° C, fully stirred, and the mixture is added dropwise and then kept for 1 hour;

[0034] S3, continue to add 33.08% ethylene glycol butyl ether dropwise, control the temperature of the reaction kettle at 65-70°C, after the dropwise addition, keep the temperature at 75°C for 2 hours, take a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com