Explosion-proof film for glass backboards

A glass backplane, explosion-proof film technology, applied in the direction of film/flake adhesives, coatings, adhesive additives, etc. The effect of market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

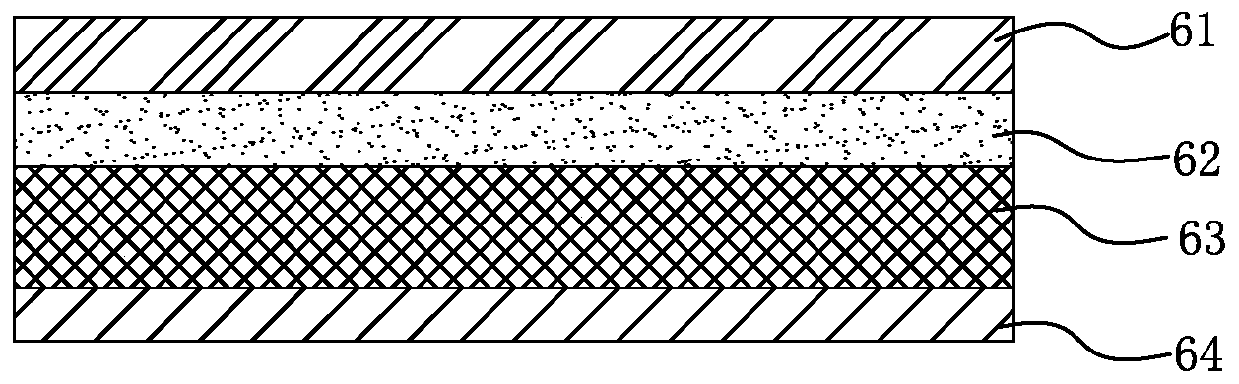

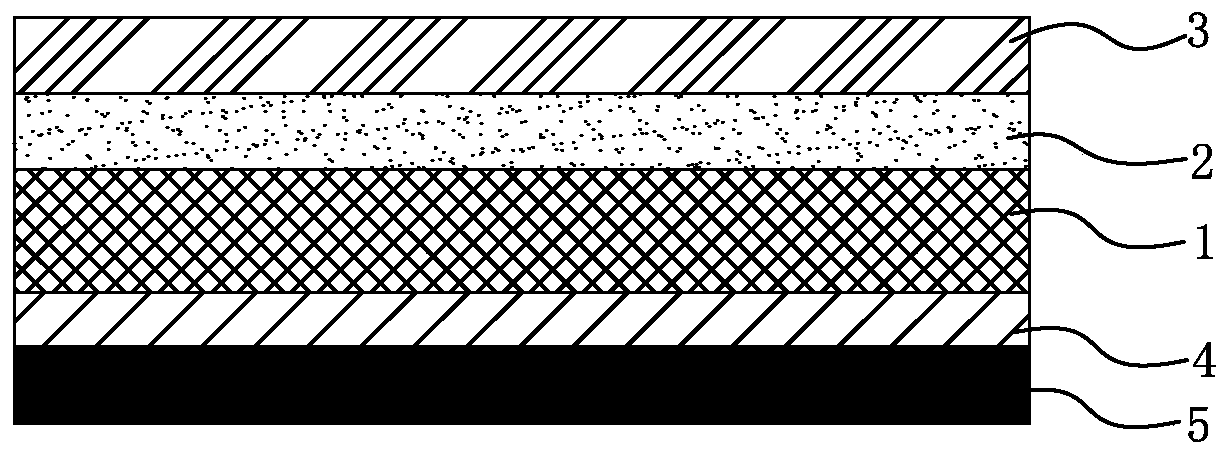

[0029] The substrate layer 1 adopts a TPU optical substrate film with a thickness of 100 microns.

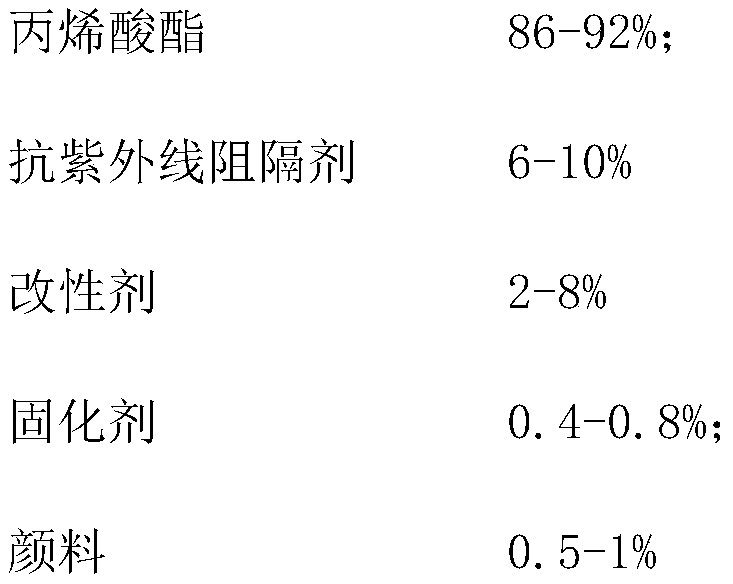

[0030] The components in the optical adhesive layer 2 and the weight ratio of each component are:

[0031]

[0032] The acrylate is epoxy methacrylate, the modifier is methacrylic acid, and the curing agent is isocyanate.

[0033] The release film 3 is a PET release film with a thickness of 100 microns. The electroplating layer is coated with aluminum powder, and the protective layer is a black ink layer.

[0034] When engraving with a laser engraving machine, a laser with a wavelength of 300nm–400nm is used, and 75% of the laser can be blocked by an anti-ultraviolet blocker, thereby greatly reducing the intensity of the laser, and at the same time ensuring that the laser passing through the optical adhesive layer 2 The engraving of the electroplating layer 4 can be completed.

[0035] The products described are as follows:

[0036] The total thickness of the whole produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com