Multi-functional multi-component composite inspection cover well

A multi-component composite inspection cover technology, which is applied in the field of inspection wells, can solve the problems of poor toughness, broken or injured people, personal casualties and other problems of iron cast manhole covers, and achieves the effects of long service life, preventing loss and preventing pedestrians from falling into wells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

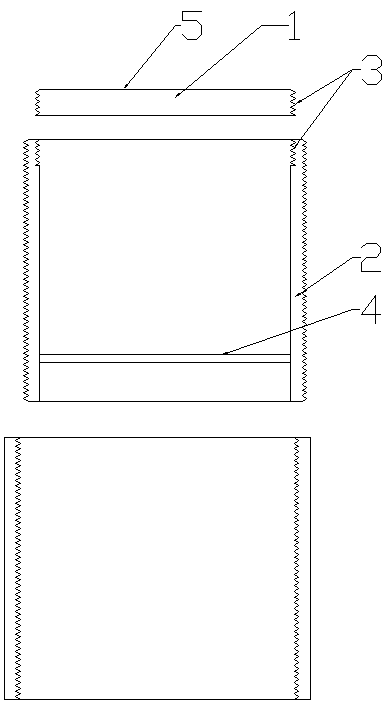

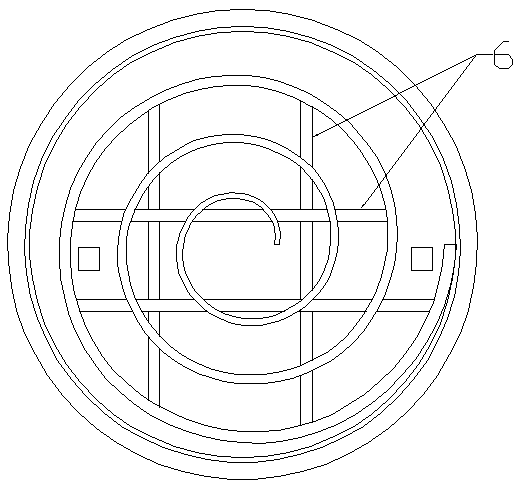

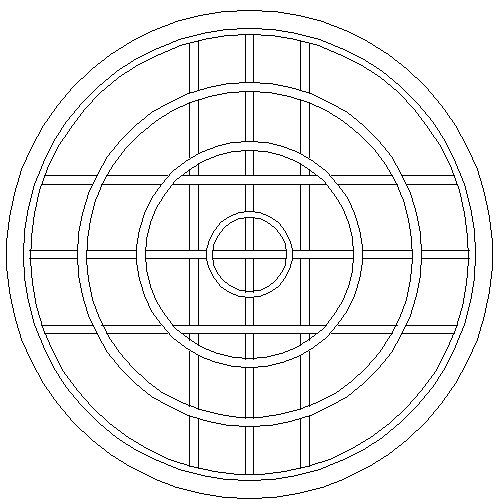

[0023] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 to attach Image 6 , the multi-component composite inspection manhole cover and wellbore described in this embodiment include a manhole cover 1 and a wellbore 2 that cooperate with each other, and the walls of the wellbore 2 are provided with strips of bamboo bars or steel strips, or spiral bamboo bars or steel strips, Reinforcing ribs are set inside the wall of the shaft, which greatly enhances the strength of the shaft and prolongs the service life of the shaft. The manhole cover 1 is provided with a ring-shaped or spiral skeleton, the skeleton runs through or is coated with reinforcing ribs 6, the gaps and surroundings of the skeleton are formed by rubber-covered rollers, and the upper surface of the manhole cover 1 is provided with a reflective tape 5 and drainage holes. The wellbore 2 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com