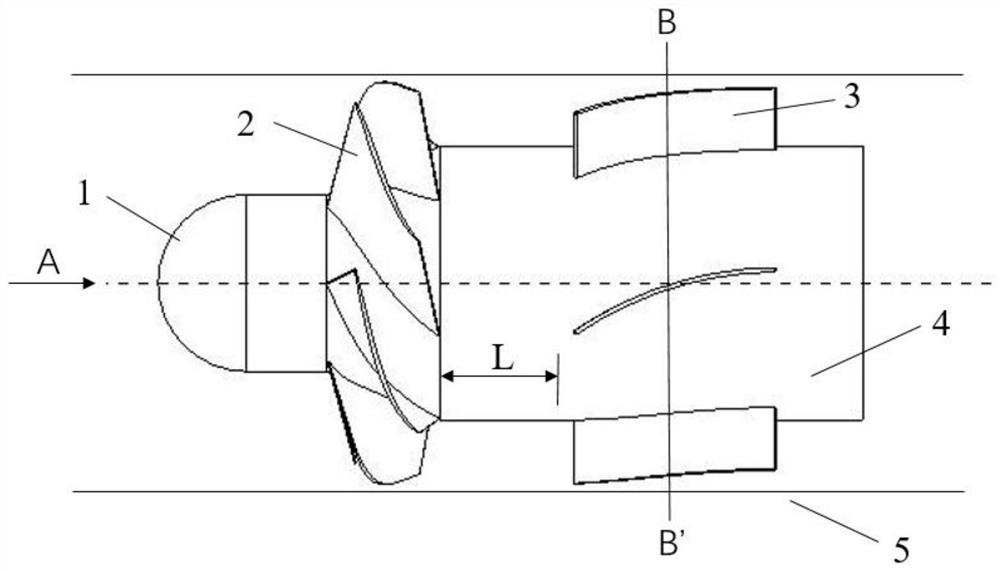

A plate-shaped rear guide vane of a diagonal flow fan and its design method

The technology of a rear guide vane and a diagonal flow fan is applied to mechanical equipment, components of a pumping device for elastic fluid, pump devices, etc., and can solve the problems of flow field deterioration and insufficient static pressure conversion capacity of guide vanes, etc. Achieve the effect of avoiding flow field deterioration, reducing dynamic and static interference, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

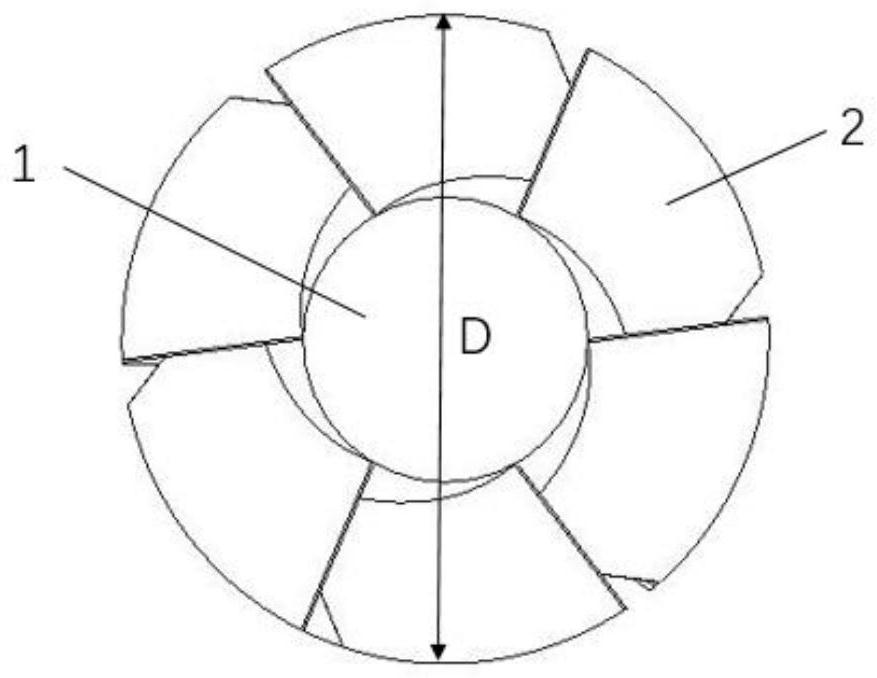

[0046] Given the diameter of the moving blade impeller D = 492mm, the number of blades N = 6. The number n of plate-shaped rear guide vanes is respectively taken as 5, 6, 7, and 11, and the fans equipped with corresponding plate-shaped rear guide vanes are respectively recorded as N5, Y, N7, and N11. The simulation calculation of four groups of wind turbines is obtained Figure 6 The full pressure curves in the and Figure 7 The total pressure efficiency curve in .

[0047] From Figure 6 and Figure 7 It can be seen that under the condition of small flow rate (Q=5500~6000m 3 / h), the total pressure and total pressure efficiency of the four groups of fans are not much different, and the effect of N7 and Y is better. It can be known that under the condition of small flow, increasing the number of guide vanes can improve the performance of the fan. Under the condition of large flow (Q=6500~7500m 3 / h), it can be seen from the two figures that the comparison relationship b...

Embodiment 2

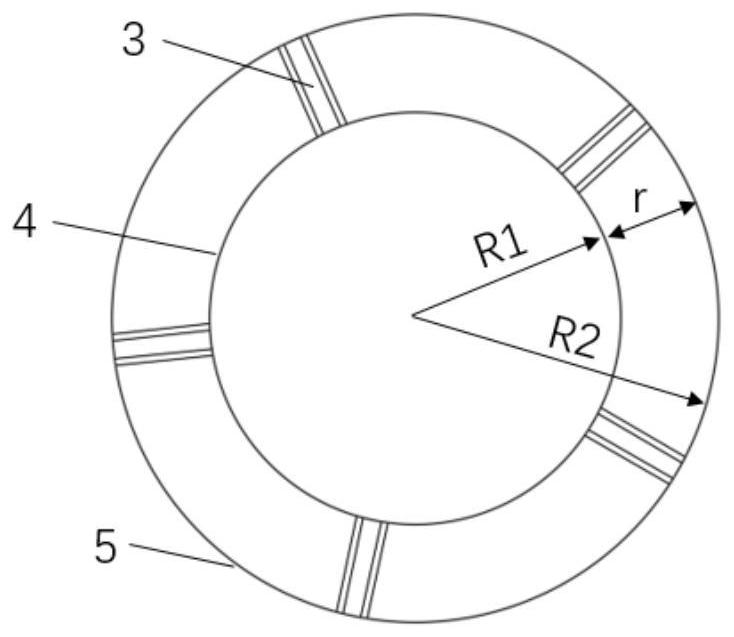

[0049] Given the diameter of the moving blade impeller D = 492mm, the number of blades N = 6. The radius R of the plate-shaped rear guide vane is respectively taken as 250mm, 300mm, 350mm, and 390mm, and the fans equipped with the corresponding plate-shaped rear guide vane are respectively recorded as R250, R300, R350, and R390.

[0050] The simulation calculation of four groups of wind turbines is obtained Figure 8 The full pressure curves in the and Figure 9 The total pressure efficiency curve in . Over the full flow range, by Figure 8 and Figure 9 It can be seen from the figure that R300 is not dominant when the flow rate is small, but as the flow rate increases, the pressure curve represented by R300 gradually rises and shows a large range of high-performance values. As the flow rate increases, the total pressure of R250 and R300 and The total pressure efficiency curve tends to be consistent. But overall, the R300 solution is better. At this time, the value is 29...

Embodiment 3

[0052] Given the diameter of the moving blade impeller D = 492mm, the number of blades N = 6. Take the axial distance L of moving and stationary blades as 20mm, 40mm, 60mm, 80mm, 100mm, 120mm, and 140mm respectively, and the fans equipped with corresponding plate-shaped rear guide vanes are recorded as L20, L40, L60, L80, L100, L120, and L140 respectively . Carry out simulation calculations on seven groups of fans, and get Figure 10 The total pressure curve and Figure 11 The total pressure curve of the fan at L=80, 100, 120, 140.

[0053] Under the condition of small flow, comprehensive observation Figure 10 and Figure 11 It can be seen that there is little difference between the schemes. Under high flow conditions, from Figure 10 and Figure 11 From the comparison of the two figures, it can be seen that the L80 scheme has the best effect; observing the total pressure, it can be found that when the axial distance is less than 80mm, the performance gradually increas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com