High-density optical fiber adaptor module

A high-density, transfer technology, applied in the direction of light guides, optics, optical components, etc., can solve the problems of poor practicability, inconvenient quick disassembly and maintenance of transfer blocks, inconvenient installation and fixing of optical fibers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

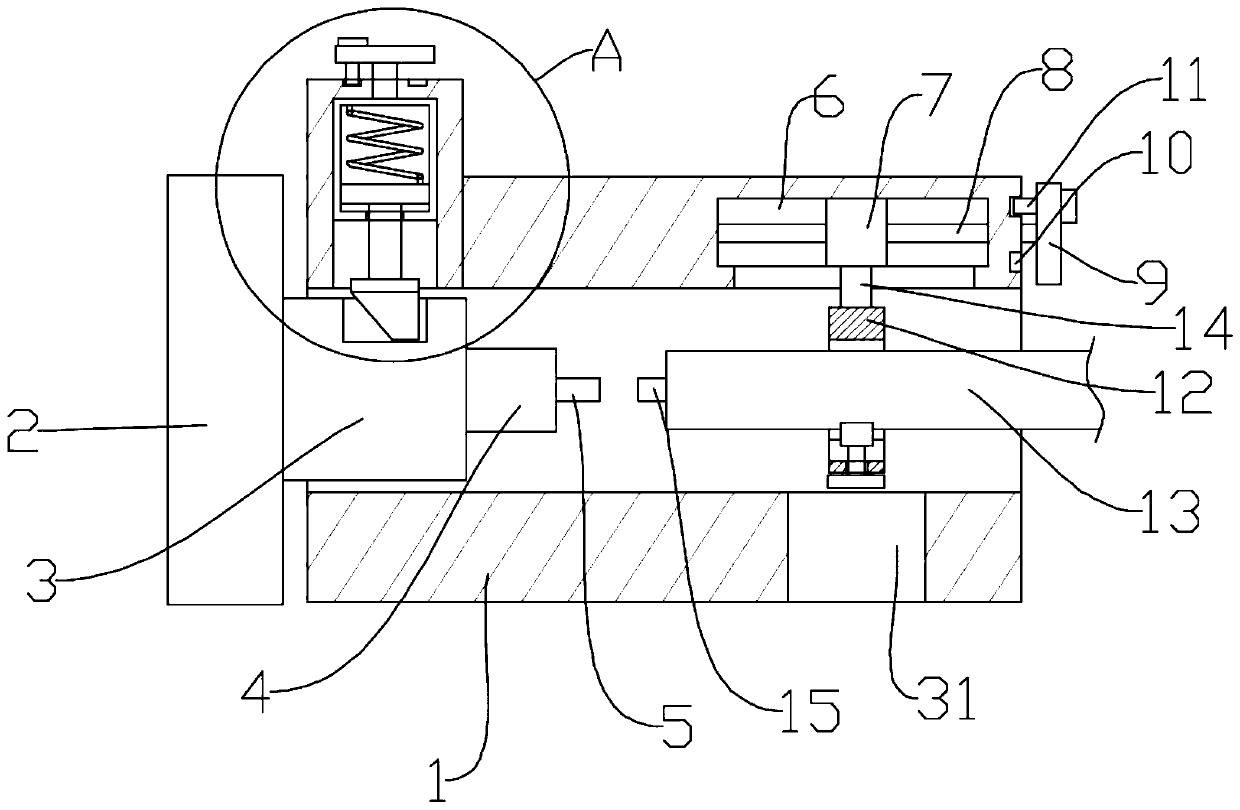

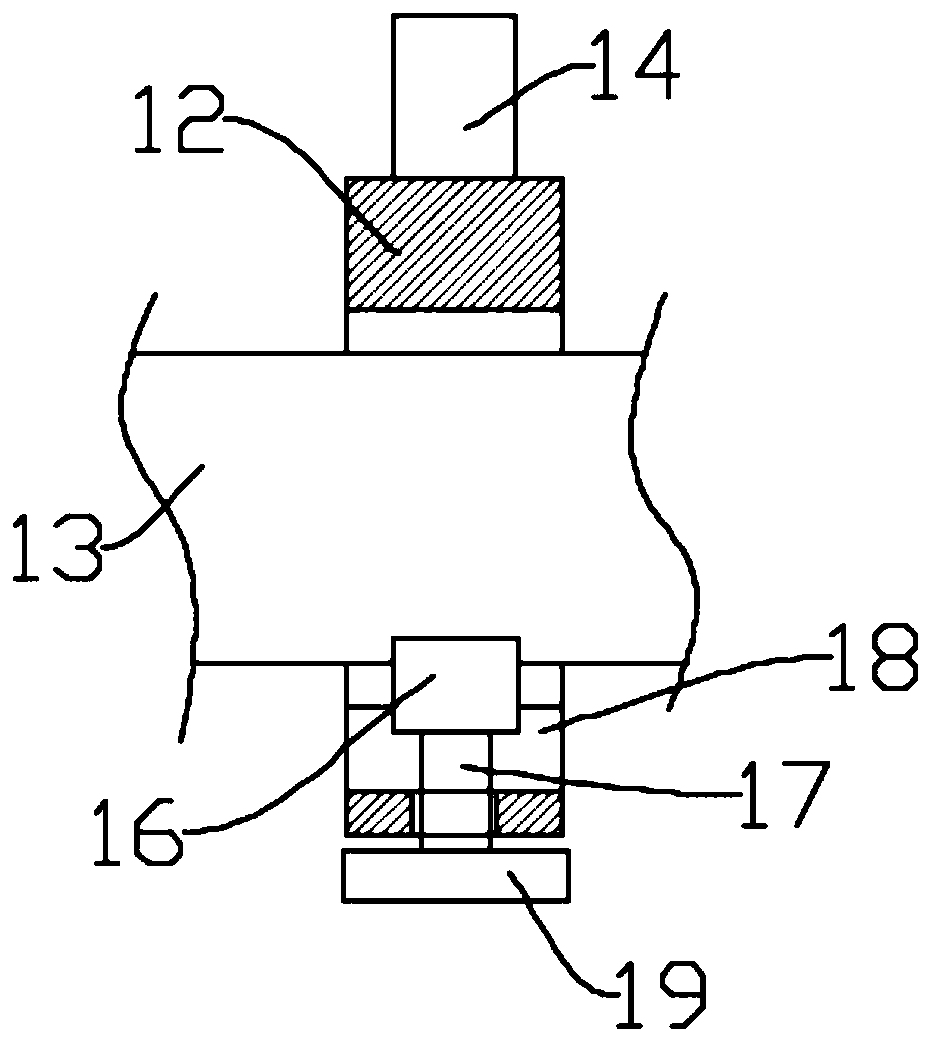

[0024] Such as figure 1 As shown, in the embodiment provided by the present invention, a high-density optical fiber transition module includes an adapter barrel 1 with both ends open, and an open end of the adapter barrel 1 is detachably installed with Connector 2, the opening of the other end of the adapter barrel 1 is detachably installed with an optical fiber 13 through a clamping assembly, and the optical fiber 13 is wrapped around the outer ring of the fiber core 15; and the other end of the adapter barrel 1 An adjustment assembly for pushing the optical fiber 13 to move towards the connector 2 is also provided.

[0025] Specifically, in the embodiment provided by the present invention, one side of the connector 2 has a connecting column 3 extending into the adapter barrel 1, and the connecting column 3 is fixedly installed with a protective cover covering the outer ring of the ferrule 5. layer 4; an installation assembly for locking and fixing the connecting column 3 is...

Embodiment 2

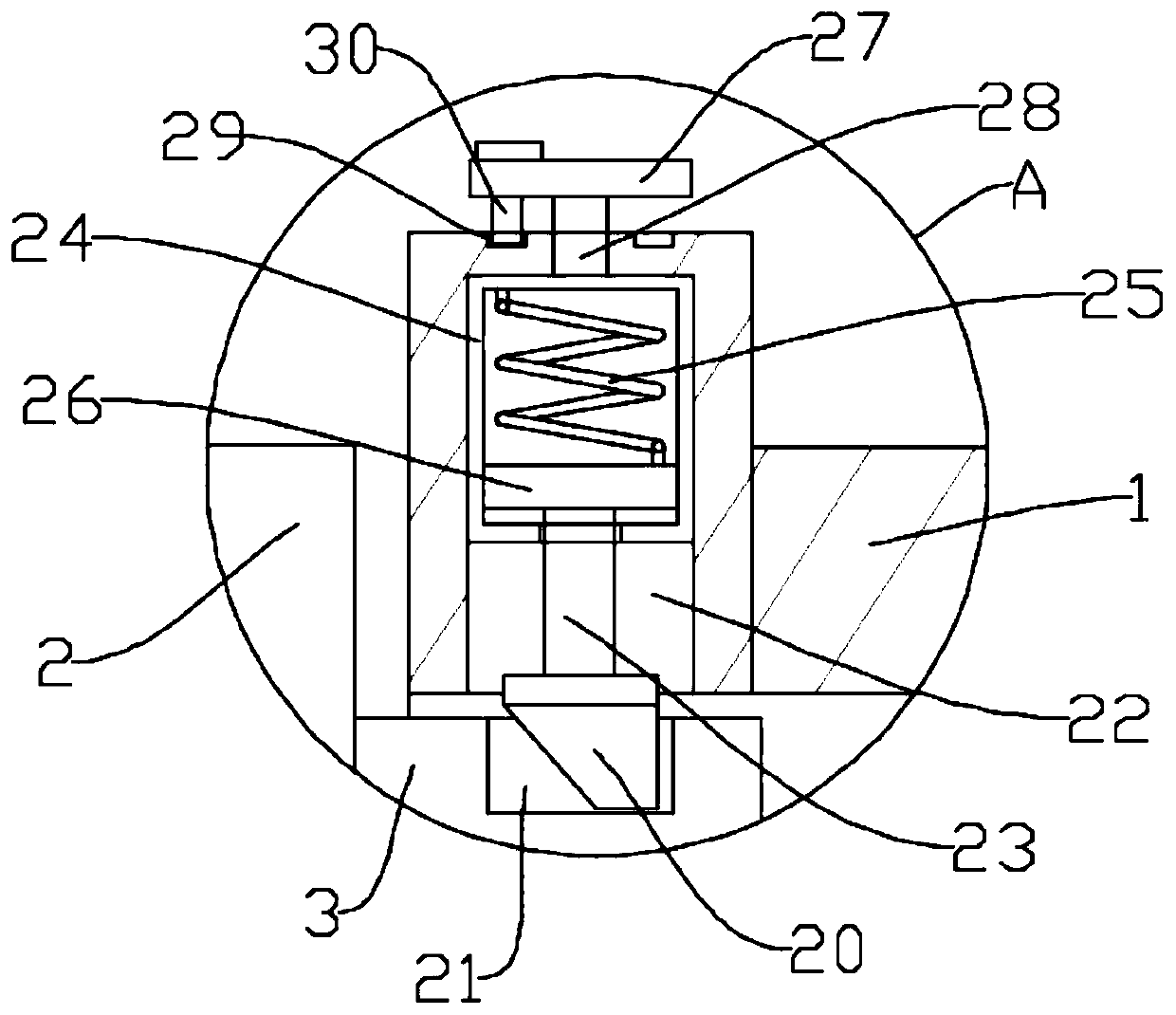

[0031] Such as figure 1 with image 3As shown, the difference from Embodiment 1 is that in the embodiment provided by the present invention, the connecting column 3 is provided with a mounting groove 21, and the mounting assembly includes a mounting block 20 that is adapted to the mounting groove 21 , the opening of the end of the adapter tube 1 is provided with a receiving groove 22, and an elastic support member is provided in the receiving groove 22 to elastically support the installation block 20, and the installation block 20 has an inclined surface The edge block structure;

[0032] Specifically, in the embodiment provided by the present invention, an operation part for adjusting the orientation of the inclined surface of the installation block 20 is also provided on the open end wall of the adapter tube 1; The elastic support member is fixedly connected to the operating shaft 28, the other end of the operating shaft 28 is fixedly mounted with the second operating disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com