Tobacco fermentation method for improving taste of cigar

A fermentation method and cigar technology, applied in tobacco, tobacco processing, application, etc., can solve problems such as changing the characteristics of cigar smoking, and achieve the effects of improving the working environment of workers, good air permeability, and reduced irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

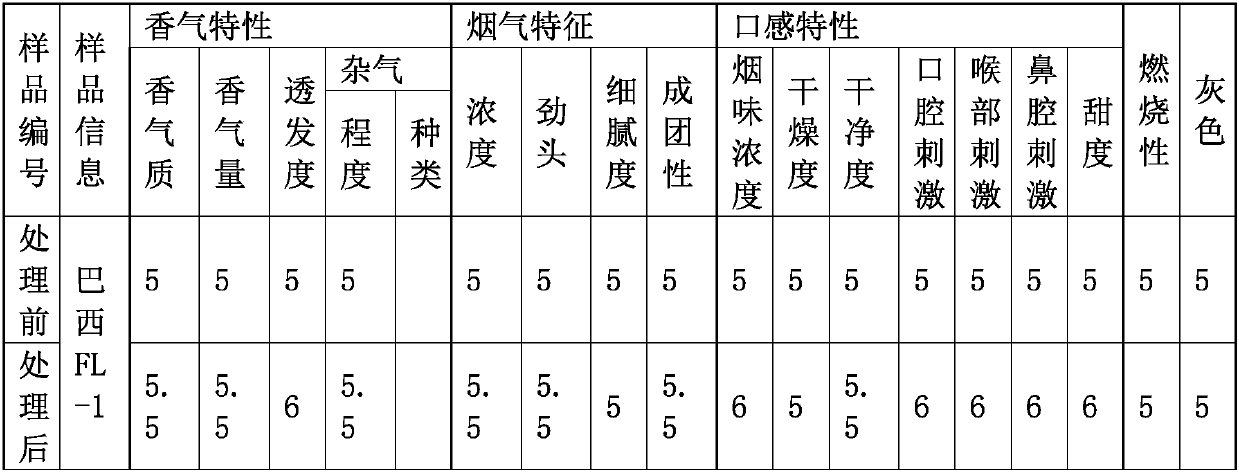

[0027] Great Wall Cigars handmade cigars Great Wall (Shengshi No. 6) products use the tobacco leaves produced by this invention, the mellow aroma, the mellow taste, and the mellow aftertaste are further enhanced, and the harmony of the burning and smoking sensibility indicators is consolidated and outstanding. It embodies the product style characteristics of Chinese cigars "sweet and soft".

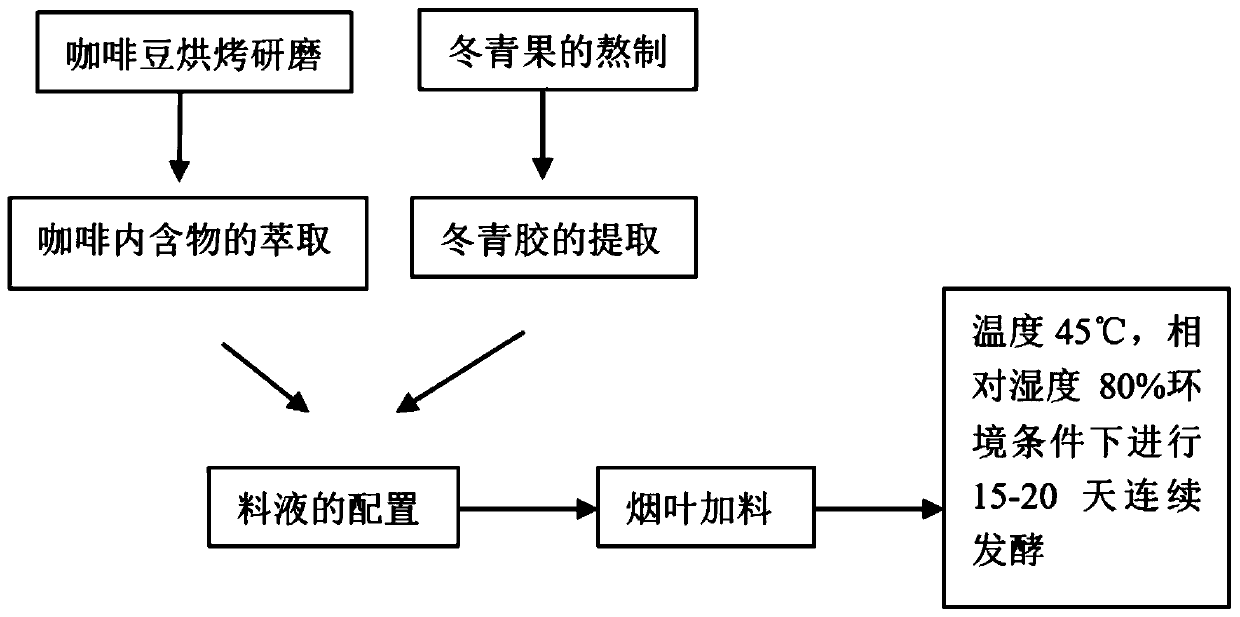

[0028] like figure 1 Shown, its fermenting method specifically comprises the following steps:

[0029] (1) Lay the air-dried tobacco raw material on the feeding table, and use the prepared feed liquid to feed it, and the feeding ratio is 7%-9%;

[0030] (2) After the surface water of the tobacco leaves is completely absorbed, put it into the sack, and place it on the wooden frame of the fermentation room where the temperature and humidity can be adjusted for continuous fermentation;

[0031] (3) Fermentation room settings: temperature: 45°C, relative humidity: 80%;

[0032] (4) It can ...

Embodiment 2

[0051] Great Wall Cigars Handmade Cigar Lion (Caribbean) products adopt the tobacco leaves produced by this invention, (in this example, the proportion of feed liquid is 9%.) The product style highlights the characteristics of oriental flavor, while the cigar aroma is soft and delicate, and the smoke is mellow Elegant and elegant, the comfort and sweetness of the mouth are emphasized, and it is extremely resistant to smoking and regional characteristics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com