Pure titanium dental implant and manufacturing method thereof

A technology of dental implant and manufacturing method, applied in the field of pure titanium dental implant and its preparation, can solve the problems of unsatisfactory osteogenesis effect and soft tissue sealing effect, and achieve the effect of high order and low degree of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the drawings, so that those skilled in the art can better understand the present invention, but the present invention is not limited in any form.

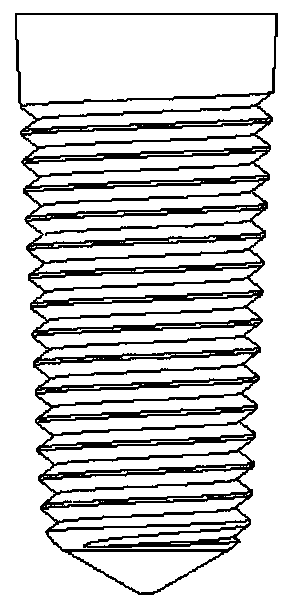

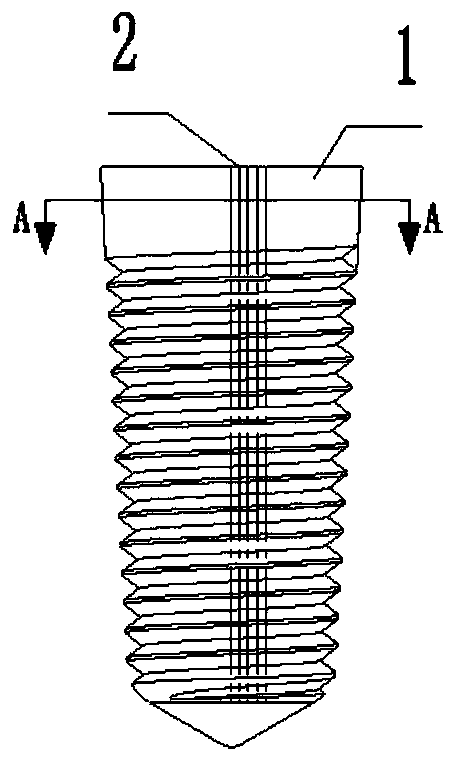

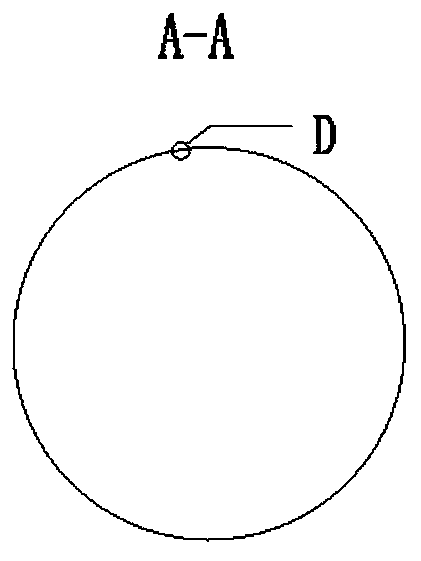

[0030] like Figure 2-7 As shown, since the size of each structure in the figure is 1000 times the order of magnitude difference, the figure is only a schematic representation of the principle structure. A pure titanium dental implant 1 has a number of micron-scale grooves 2 on the surface of the pure titanium dental implant, the grooves are evenly distributed along the circumferential surface of the implant, and the longitudinal height is from the top surface to the end point of the root thread. Nanotubes 3 perpendicular to the central axis of the dental implant are prepared, and the nanotubes are evenly and densely distributed on the surface of the dental implant.

[0031] Isotropic micron-scale groove morphology was prepared on the surface of pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com