Multi-nozzle 3D printer parallel printing method

A 3D printer and multi-nozzle technology, applied in 3D object support structure, additive manufacturing, processing data acquisition/processing, etc., can solve the problems of complex implementation, high cost, and limited placement position, and improve printing efficiency and printing efficiency High, zoning-accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below, with reference to the accompanying drawings and specific embodiments, the parallel printing method of the multi-nozzle 3D printer of the present invention will be further described, so as to facilitate a clearer understanding of the technical idea claimed in the present invention.

[0045] Embodiments of the method for parallel printing of multi-nozzle 3D printers:

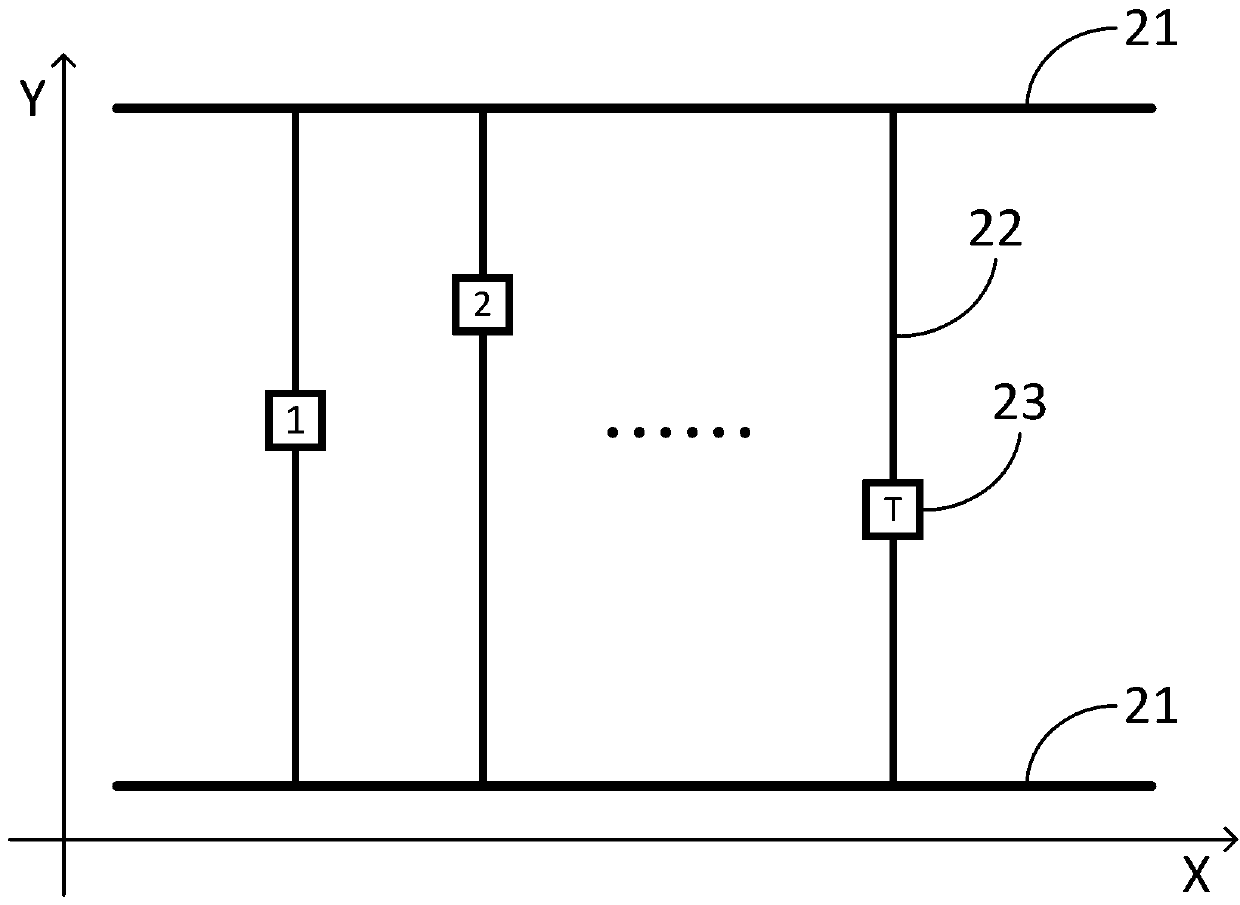

[0046] figure 2 Shown is a schematic diagram of the motion structure with a plurality of independent nozzle assemblies. The X-axis guide rail 21 is provided with a plurality of Y-axis guide rails 22. The axis guide rails 22 can all move independently on the X-axis guide rails 21 , and this embodiment will describe a method for parallel printing with multiple nozzles based on this structure.

[0047] The method for multi-nozzle parallel printing provided in this embodiment includes:

[0048] (1) Obtain the model file, analyze the model file, and add the corresponding support structure where the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com