Food packaging film printing device

A technology of food packaging film and printing device, applied in printing, printing press, transportation and packaging, etc., can solve problems such as economic loss, ink flow, overlap, etc., to speed up drying and avoid folding together.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

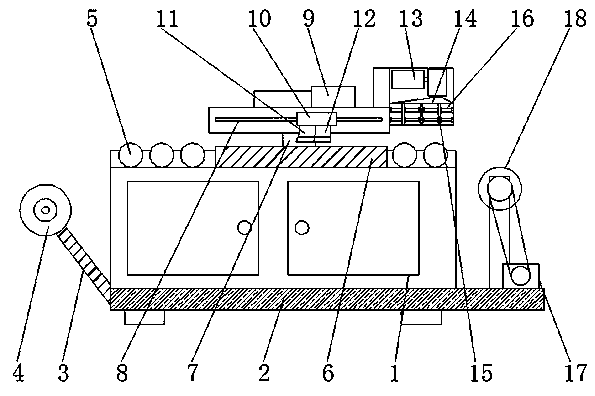

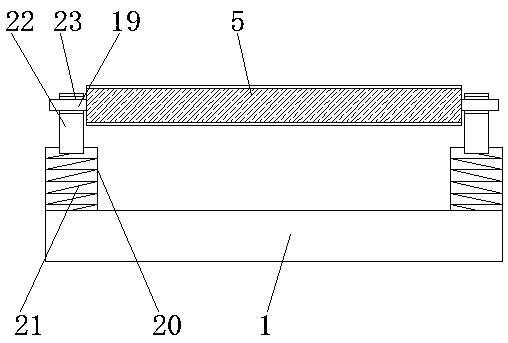

[0020] refer to Figure 1-2 , a food packaging film printing device, comprising an electrical cabinet 1, a base plate 2 is fixedly installed on the outer surface of the bottom end of the electrical cabinet 1, and a support rod 3 is fixedly connected to the outer surface of one end of the base plate 2, and a raw material is movably installed on the support rod 3 Roller 4, the outer surface of the upper end of the electrical cabinet 1 is provided with a transmission roller 5 and a printing table 6, and the outer surface of the rear end of the printing table 6 is fixedly connected with a column 7, and the outer surface of the upper end of the column 7 is fixedly connecte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap