An intelligent papermaking raw material warehouse control system

A technology of control system and raw material warehouse, applied in the field of papermaking raw materials, can solve problems such as the influence of raw material temperature, unsatisfactory insulation performance and thermal insulation performance of the warehouse body, etc., and achieve the effect of preventing quality fission and preventing mold growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

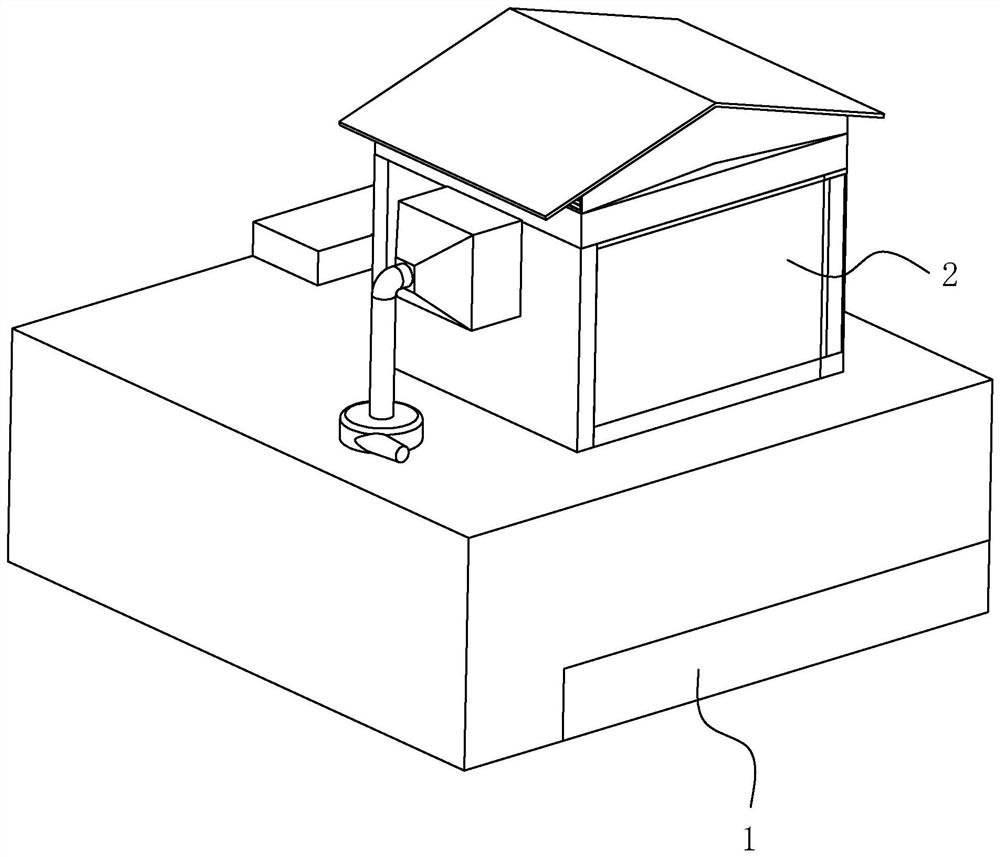

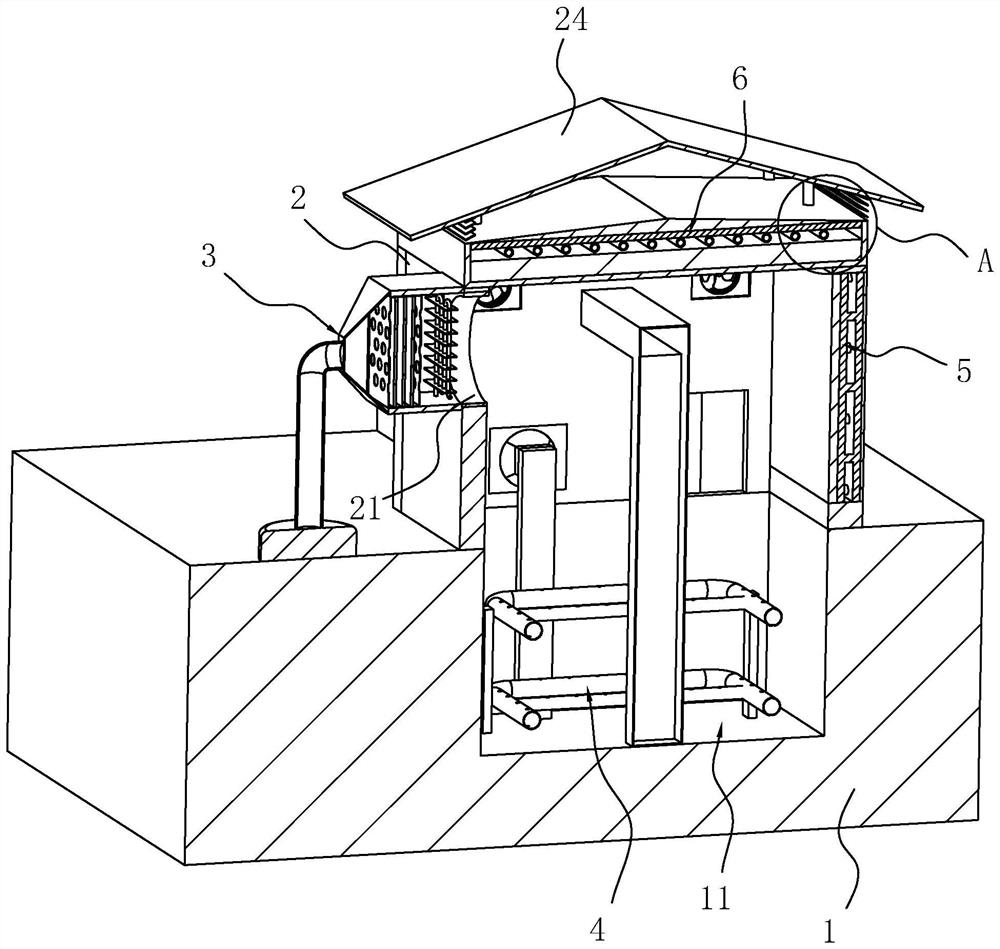

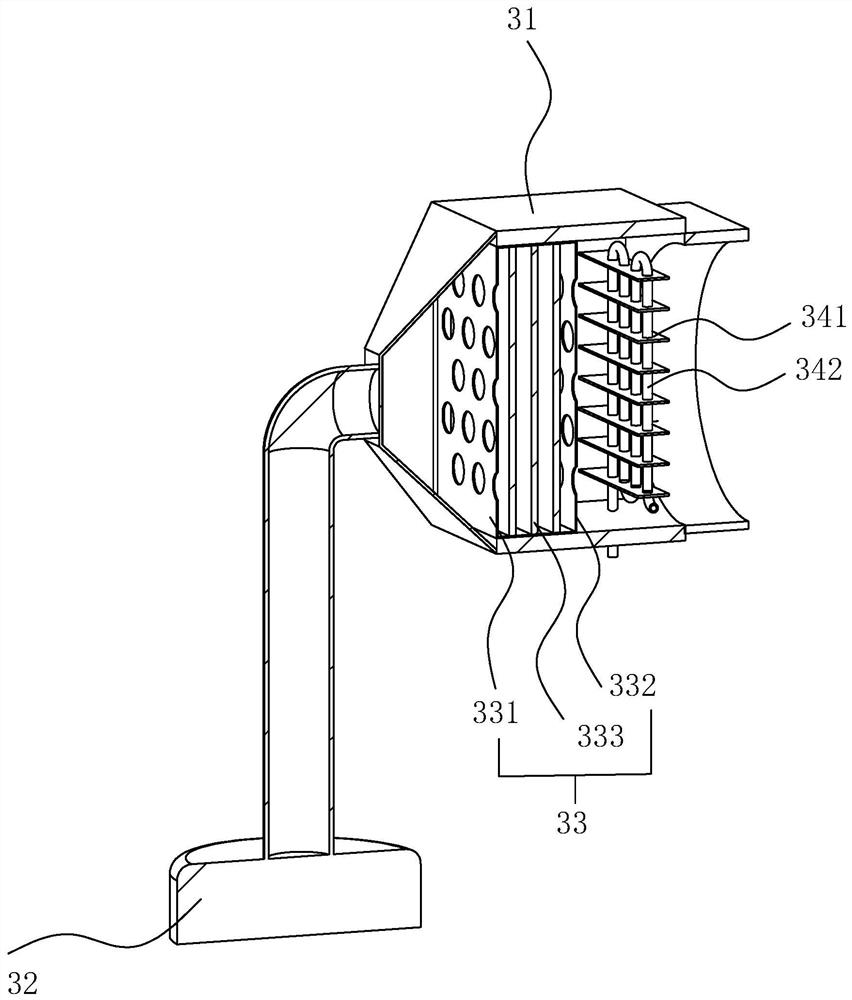

[0041] An intelligent papermaking raw material warehouse control system, see figure 1 and figure 2 , including a warehouse body 2 fixed on the ground 1, a cavity 11 communicating with the warehouse body 2 for storing raw materials is provided under the ground 1, and one side of the warehouse body 2 is provided with ventilation to the warehouse body 2 to adjust Ventilation mechanism 3 for the raw material temperature in the bin body 2 , a cooling mechanism 4 extending into the cavity 11 under the ground 1 is provided on the side of the bin body 2 perpendicular to the ventilation mechanism 3 . The ventilation mechanism 3 sends hot or cold air into the warehouse body 2 according to the temperature of the raw materials in the warehouse body 2, so as to ensure that the raw materials in the warehouse body 2 are in the optimal storage temperature range, because the weight of the raw materials at the bottom of the warehouse body 2 is relatively large , so the temperature of the raw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com