Device and method for self-traction winding high-voltage line on single traction rope

A traction rope and self-traction technology, applied in the direction of the hoisting device, the spring mechanism, etc., can solve the problems of inconvenient operation, falling equipment or personnel, and high difficulty in the operation of the spraying robot, and achieve the effect of light overall structure and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described in detail below. The following description of the preferred embodiments of the present invention is more specific, but it should not be understood as a limitation on the scope of patent protection of the present invention.

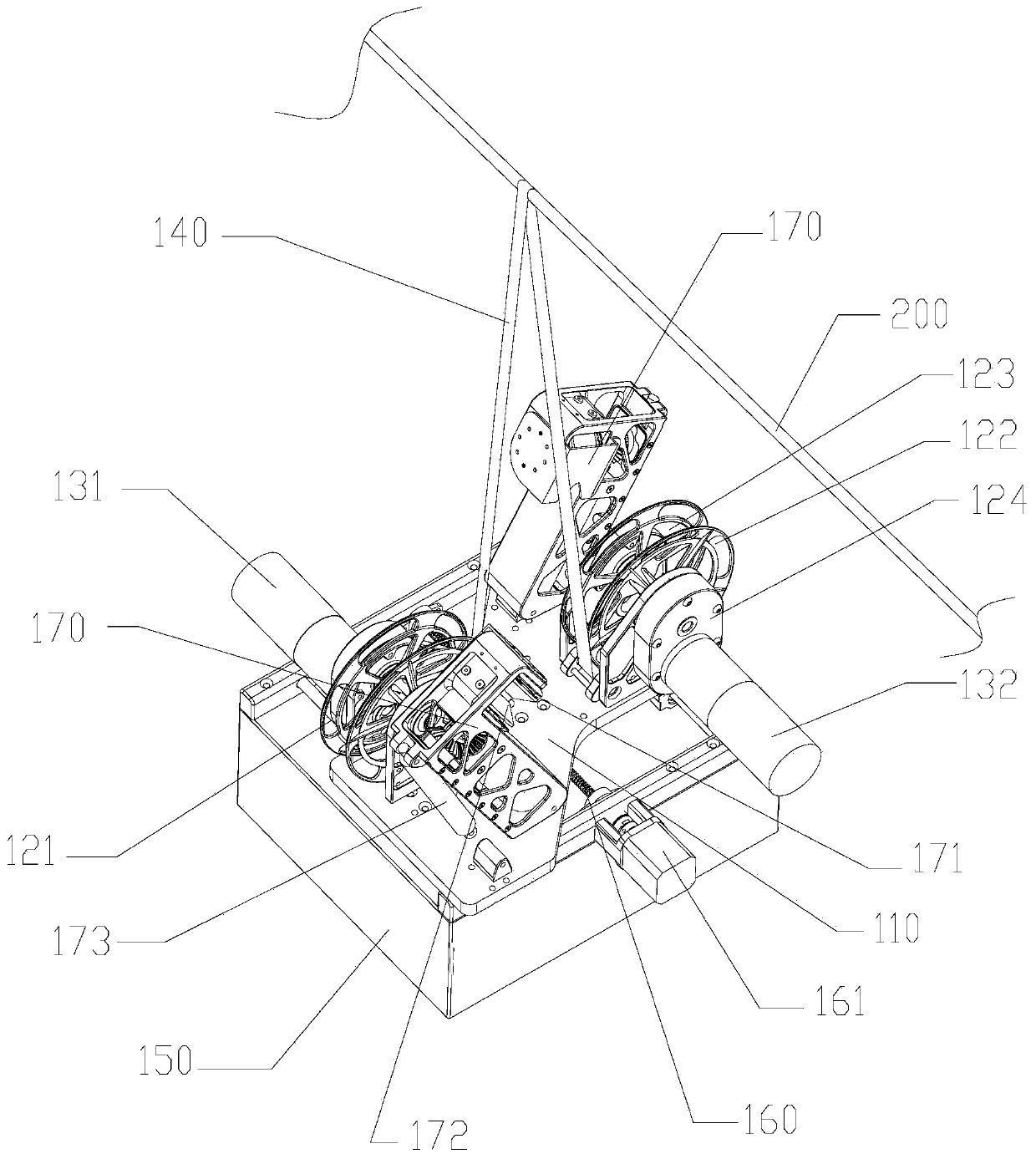

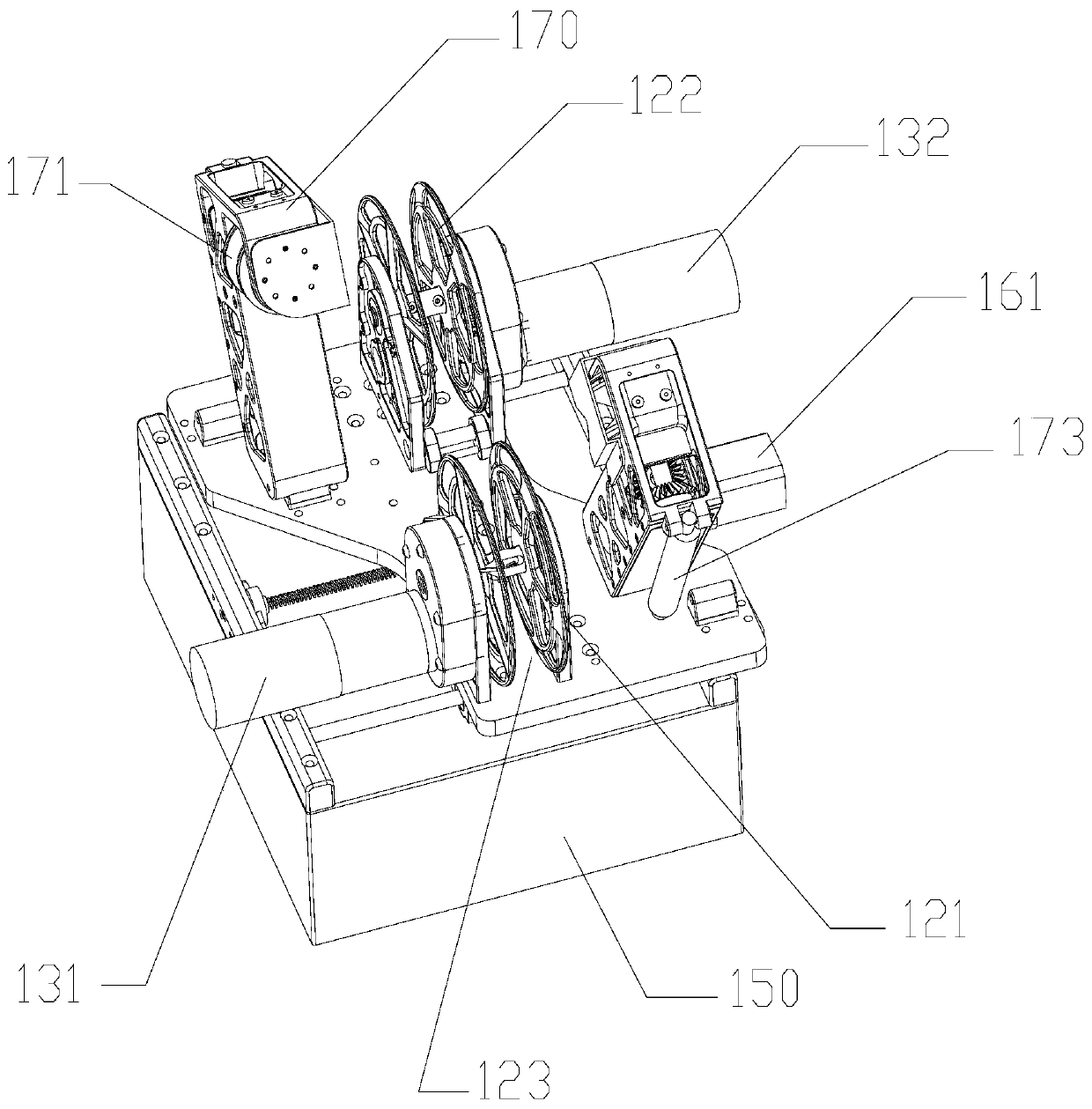

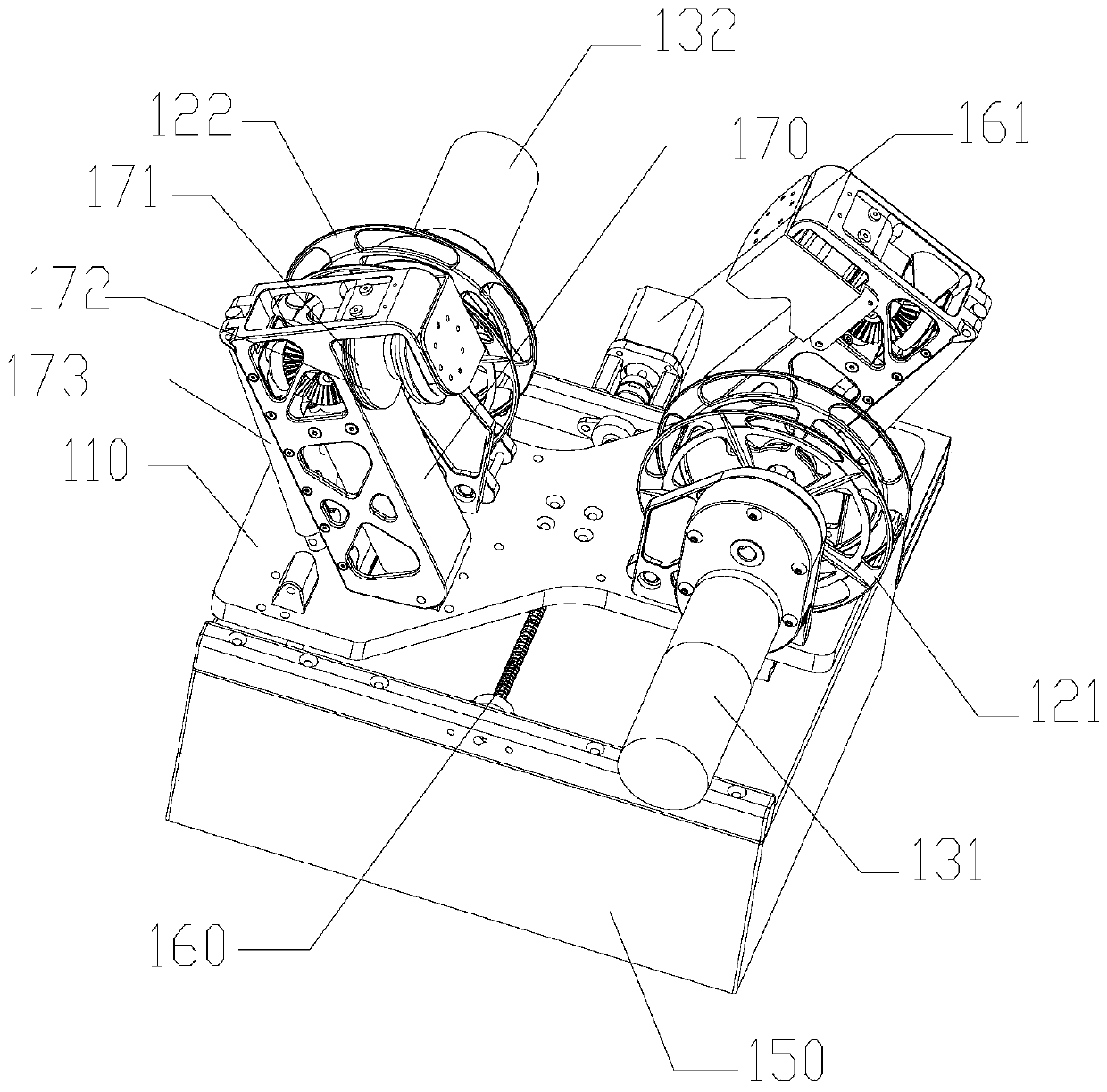

[0026] The preferred embodiment of the device for hoisting a high-voltage line on a single traction rope by self-traction, such as figure 1 As shown, the arrangement includes a base plate 110, and the base plate 110 can be a steel plate and arranged in a centrally symmetrical waist shape to reduce weight as much as possible. Two suspension wheels 121 and 122 are provided on the base plate 110. The two suspension wheels are arranged symmetrically and side by side. Each suspension wheel 121 and 122 is provided with a first motor 131 and 132 respectively. , It is also arranged in a center-symmetric manner, that is, the combination direction of the first motor 131 and the suspension wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com