Preparation method of ABS plastic standard sample containing tiny amount of lead

A technology of ABS plastic and standard sample, applied in the field of plastics, can solve the problems affecting the quality detection accuracy of heavy metal content of ABS plastic, lack of stability, etc., and achieve the effect of good uniformity of standard material, little influence of matrix and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A kind of preparation method that contains trace lead ABS plastic standard sample, its step is:

[0014] a) Dry the ABS at 85°C for 3 hours;

[0015] b) Weigh 50.00g of waste ABS, 0.05g of lead stearate, 0.50g of phthalate coupling agent, ABS:lead stearate=1000:1 (mass ratio);

[0016] c) Mix ABS, lead stearate, and coupling agent evenly and add it to the torque rheometer at a speed of 30 rpm and a temperature of 210°C, and take it out after 15 minutes of reaction;

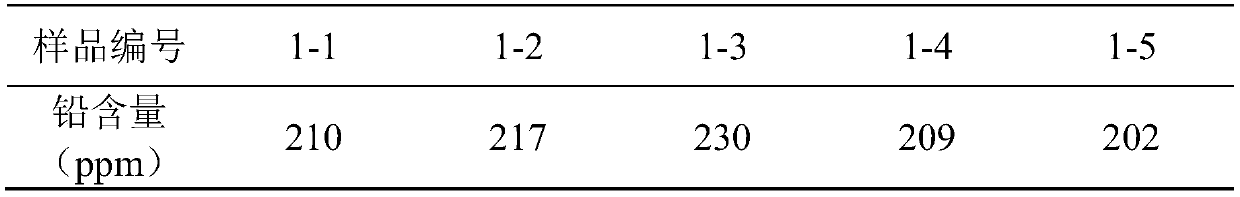

[0017] d) Extruded through an extruder and crushed into pellets by a crusher. The measured lead content is shown in Table 1 below.

[0018] Table 1 Example 1 gained standard contains trace lead ABS pellets

[0019]

Embodiment 2

[0021] A kind of preparation method that contains trace lead ABS plastic standard sample, its step is:

[0022] a) Dry the ABS at 85°C for 3 hours;

[0023] b) Weigh 50.00g of waste ABS, 0.10g of lead stearate, 1.00g of phthalate coupling agent, ABS:lead stearate=1000:2 (mass ratio);

[0024] c) Mix ABS, lead stearate, and coupling agent evenly and add it to the torque rheometer at a speed of 30 rpm and a temperature of 210°C, and take it out after 15 minutes of reaction;

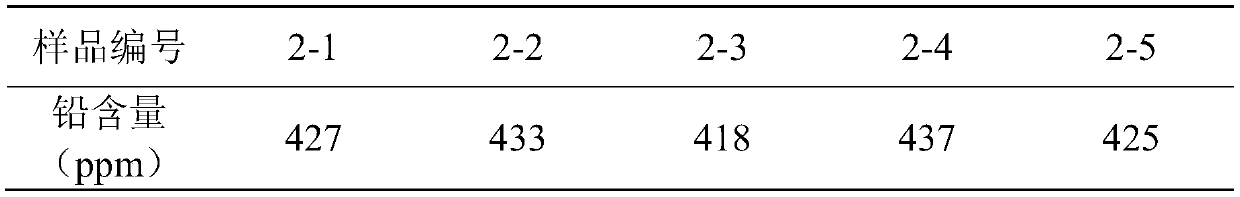

[0025] d) Extruded through an extruder and crushed into pellets by a crusher. The measured lead content is shown in Table 2 below.

[0026] Table 2 embodiment 2 gained standard contains trace lead ABS pellet

[0027]

Embodiment 3

[0029] A kind of preparation method that contains trace lead ABS plastic standard sample, its step is:

[0030] a) Dry the ABS at 85°C for 3 hours;

[0031] b) Weigh 50.00 g of waste ABS, 0.15 g of lead stearate, 1.50 g of phthalate coupling agent, ABS:lead stearate=1000:3 (mass ratio);

[0032] c) Mix ABS, lead stearate, and coupling agent evenly and add it to the torque rheometer at a speed of 30 rpm and a temperature of 210°C, and take it out after 15 minutes of reaction;

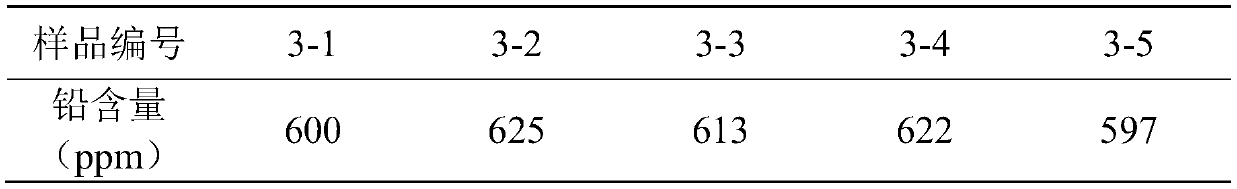

[0033] d) Extruded through an extruder and crushed into pellets by a crusher. The measured lead content is shown in Table 3 below.

[0034] Table 3 embodiment 3 gained standard contains trace lead ABS pellets

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com