Method for producing variable satin weave fabric

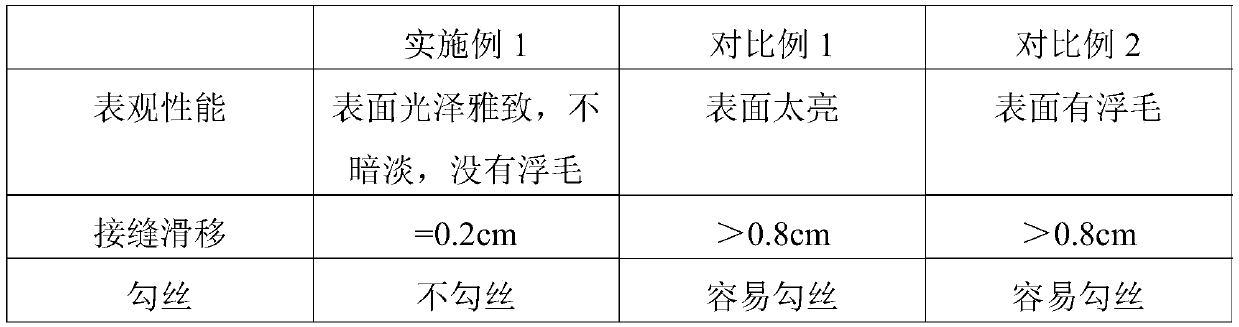

A fabric and satin weave technology, which is applied in the field of fabric preparation with changing satin weave, can solve problems such as dull appearance, inability to meet the quality requirements of business men's clothing, and simple weaving, so as to improve the tightness and smoothness of the cloth surface and reduce the joint. Risk of seam slippage and snagging, improved pilling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a fabric with a changing satin weave, twisting the warp and weft yarns, drawing in the harness, and weaving the satin surface to obtain the fabric, and then passing through a continuous desizing machine to remove the yarn size, and then overflowing at high pressure Coloring is carried out in the dyeing machine. After the coloring is completed, it is washed in the vat to ensure the color fastness and no floating color on the surface. , after the completion, the fabric is shaped by a high-temperature setting machine. The final product is inspected and packaged in rolls.

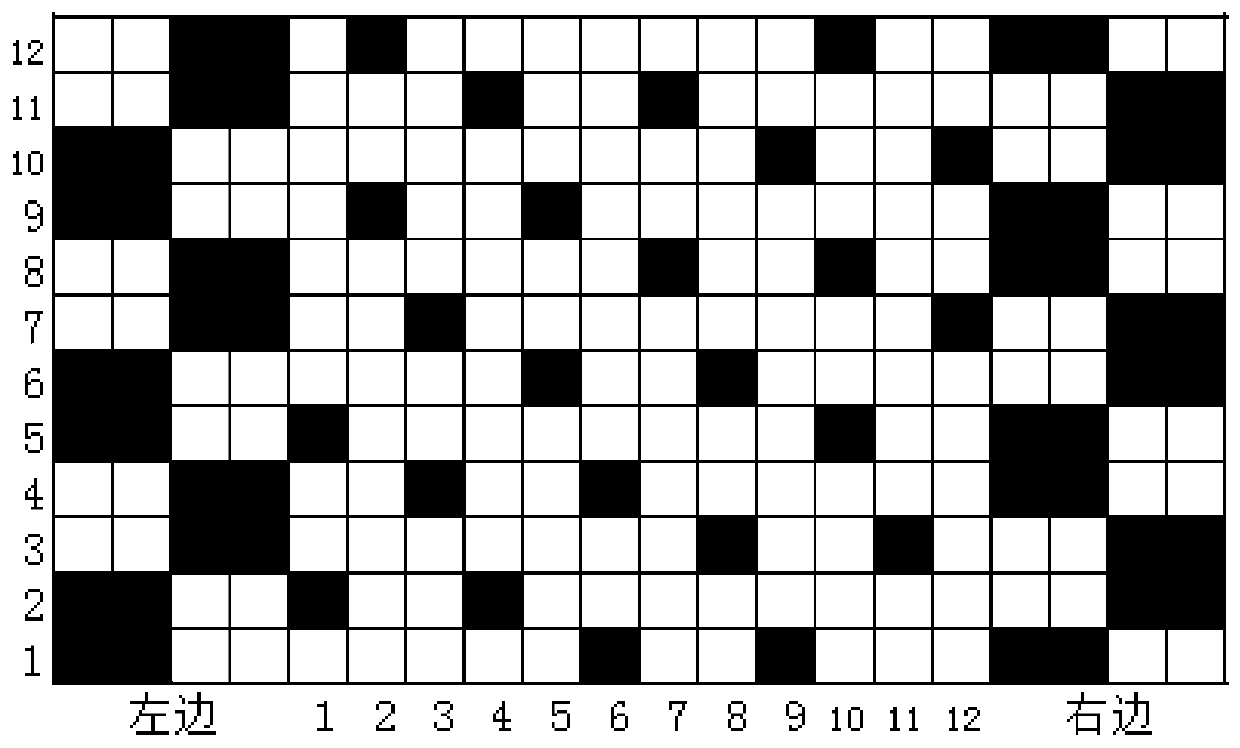

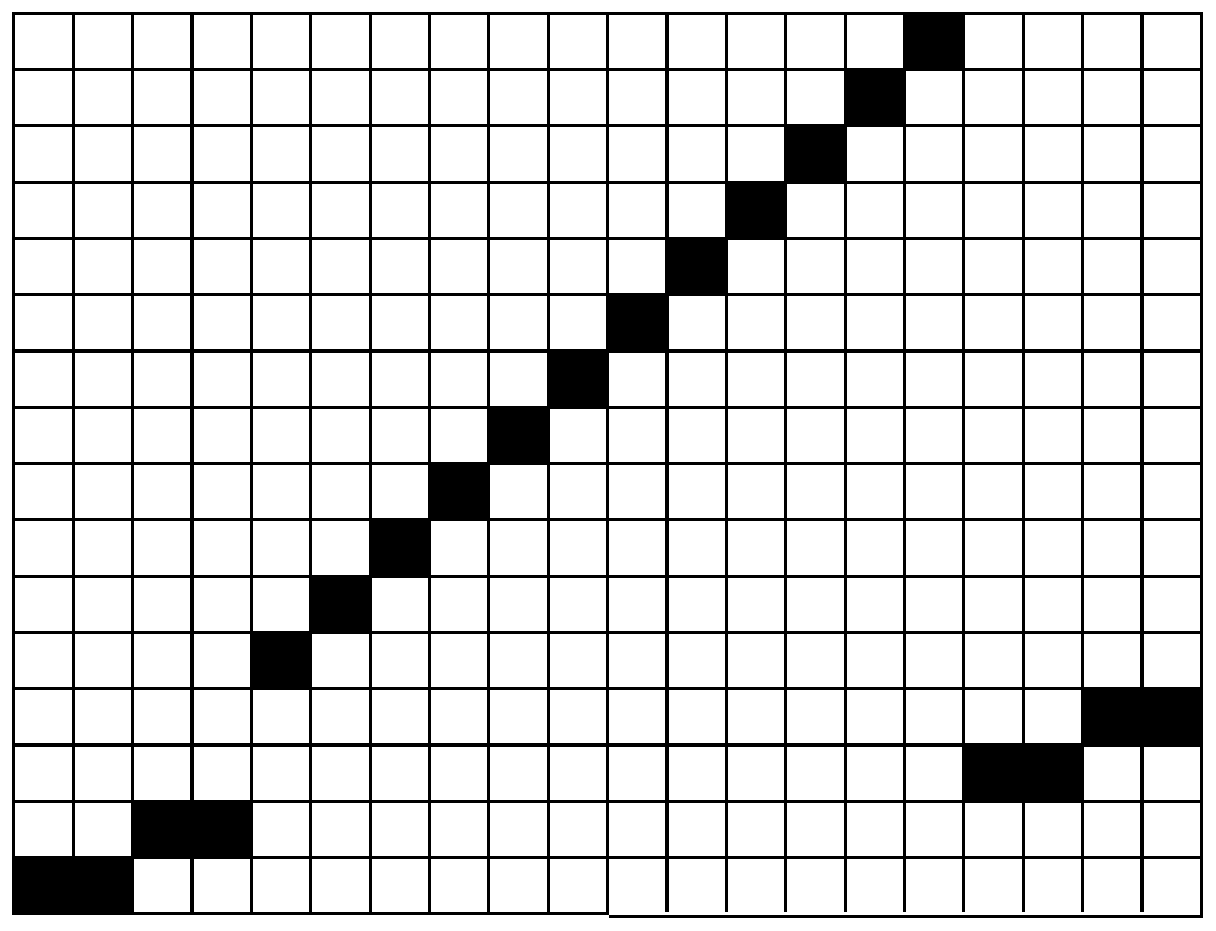

[0029] In this embodiment, the warp yarn is 50D / 72F glossy polyester DTY plus S twist; the weft yarn is 150D / 144F semi-gloss polyester DTY plus S twist. The heald frame has an inner diameter of 12 pages of healds, and the healds are threaded in the order of 1 to 12, please refer to figure 1 and figure 2 shown. In the satin weaving process, the warp and weft are weaved accordin...

Embodiment 2

[0039] Compared with Example 1, most of them are the same, except that it is further defined in this example:

[0040] The finishing process specifically includes: putting the washed and dried fabric in softening liquid for finishing. The formula of softening liquid used is: 1wt% softening agent (transfer chemical), 3wt% water repellent (daily chemical), 1wt% antistatic agent (transhua chemical) 95wt% clear water, stir for 5 minutes, put into resin The groove is used for soaking the cloth when setting the shape. After finishing, the hand feeling, waterproof and antistatic properties of the fabric are all improved, and there is basically no interference with each other.

Embodiment 3

[0042] Compared with embodiment 1 or 2, most of them are all the same, except further defining in this embodiment:

[0043] The desizing process specifically includes: soaking in 95°C high-temperature alkaline water at a speed of 40m / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com