Sinking type toilet suspension template structure and construction method thereof

A construction method and toilet technology, applied in the direction of formwork/template/work frame, connection parts of formwork/formwork/work frame, building structure, etc. Expansion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

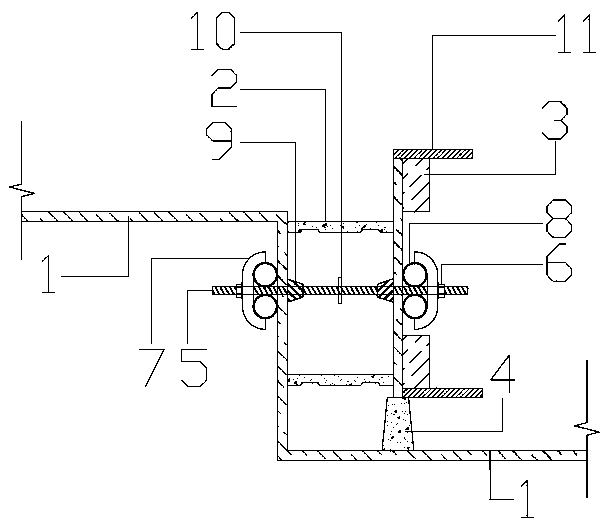

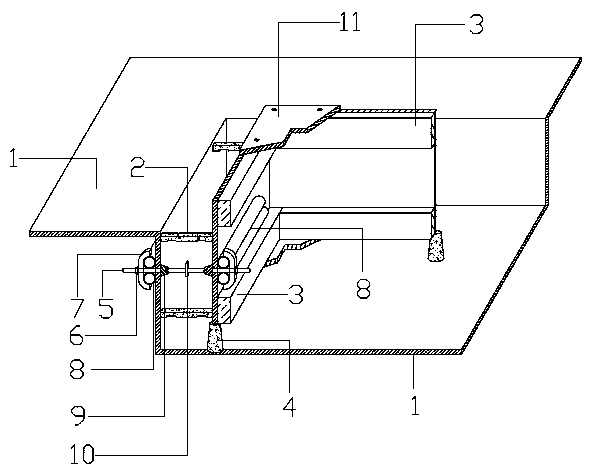

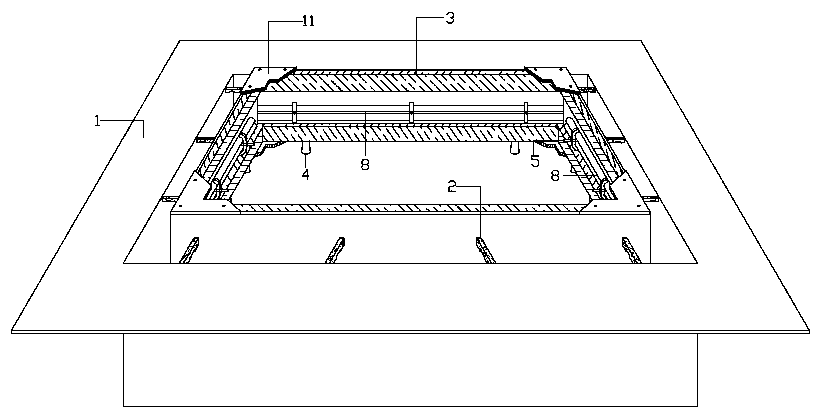

[0018] The specific implementation of this embodiment will be described in detail below in conjunction with the drawings in the specification:

[0019] Such as Figure 1-3 As shown, a sunken toilet suspended form structure, the suspended form structure includes a template, a cement strip, a wooden square, a truncated cone-shaped precast concrete pad, a water stop bolt, a steel pipe, and a triangular template, and the template is set in The bottom of the floor and the two sides of the beam are used as supporting forms. The cement strips are placed on the upper and lower parts of the inner surface of the formwork on both sides of the beam to ensure the beam section size and the thickness of the steel protection layer. At the bottom and the top, the truncated cone-shaped prefabricated concrete pads are set on the bottom support of the formwork inside the bathroom beam, and the thickness of the bathroom floor slab is ensured; the water stop bolt penetrates through the formwork on bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com