Full-disc brake for heavy vehicle

A technology for heavy-duty vehicles and brakes, applied in the direction of brake types, brake components, mechanical drive clutches, etc., can solve the problems of not being very extensive and limited braking torque potential, and achieve good results, easy layout, and simple and convenient maintenance and replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

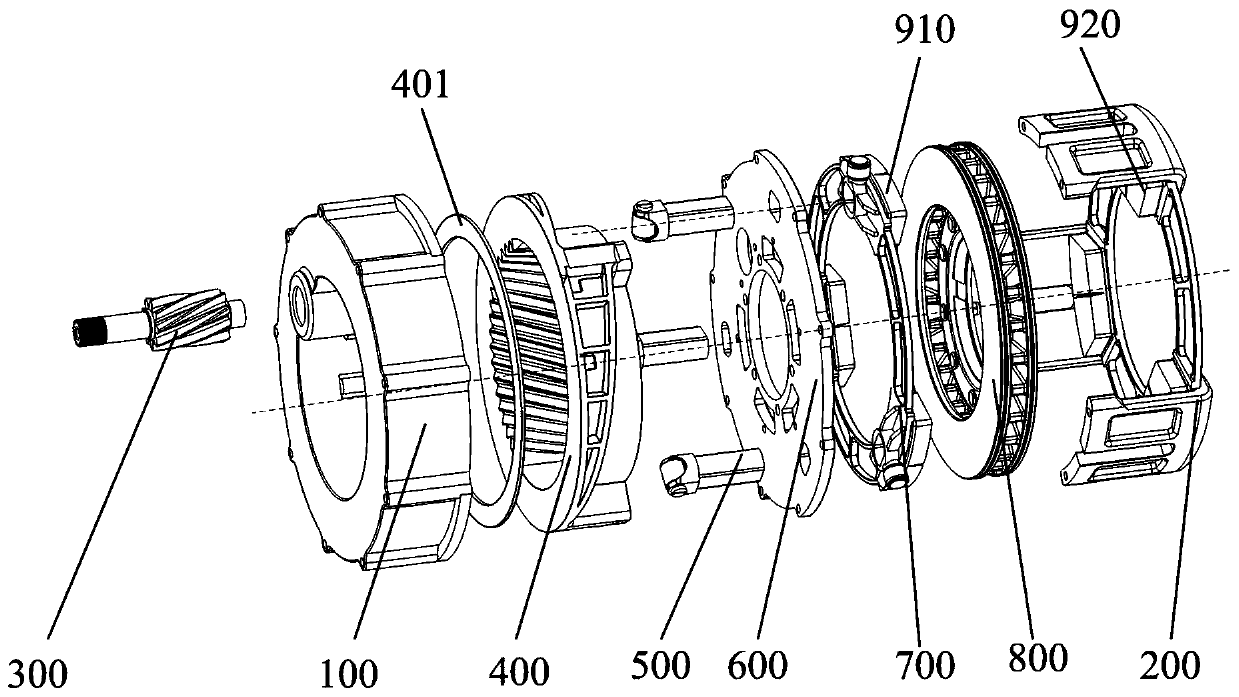

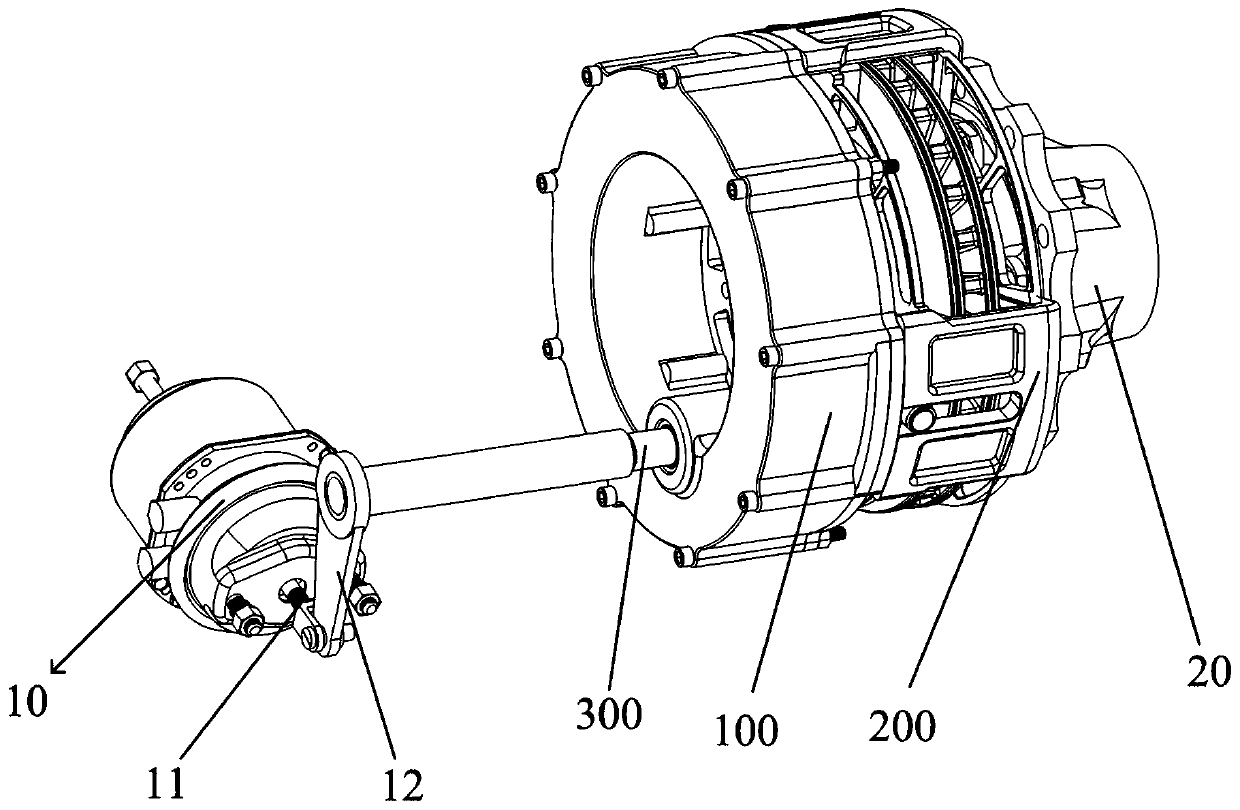

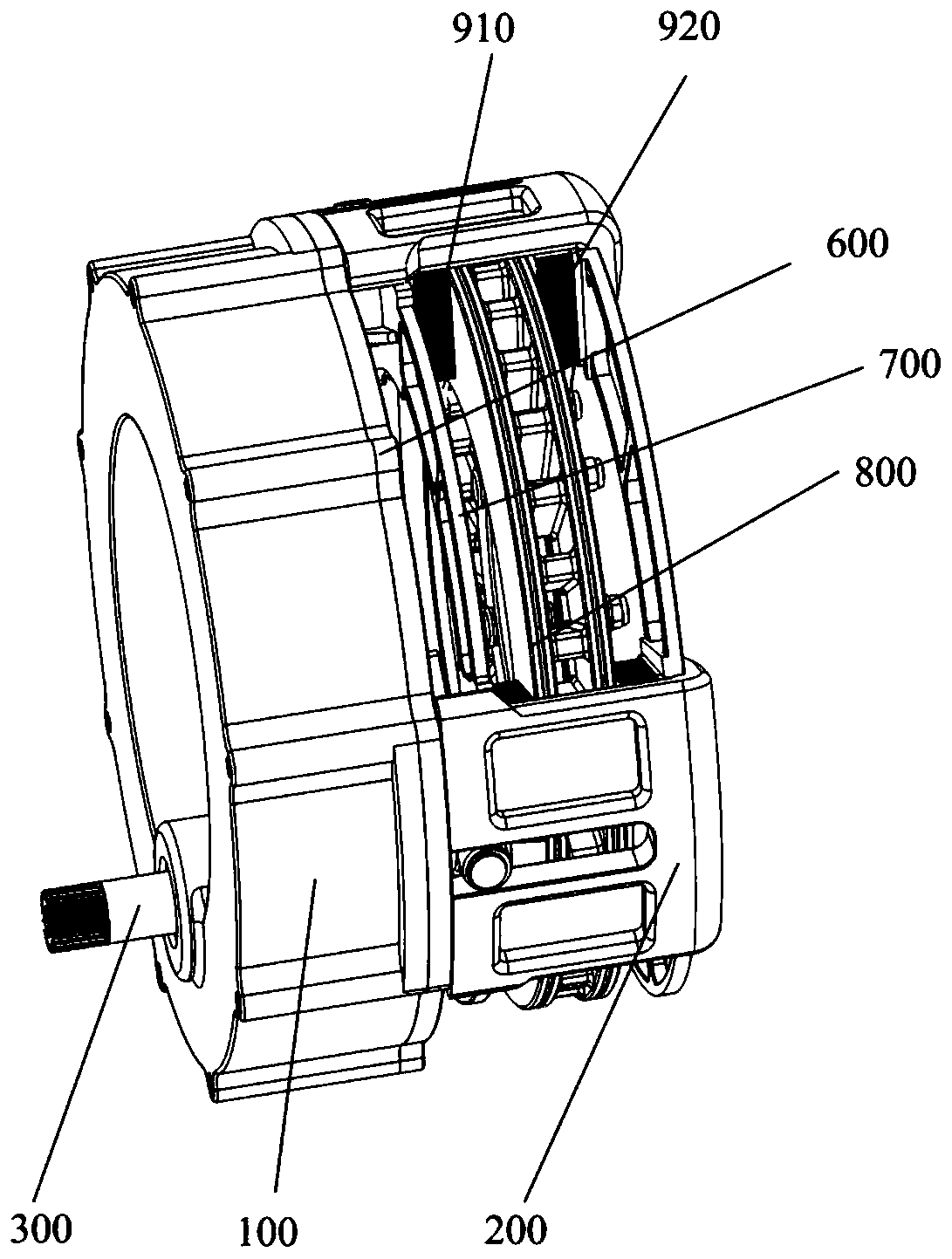

[0031] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the embodiments and drawings. Here, the exemplary embodiments of the present invention and the description thereof are used to explain the present invention, but not as a limitation to the present invention.

[0032] Here, it should also be noted that, in order to avoid obscuring the present invention due to unnecessary details, only the structure and / or processing steps closely related to the solution according to the present invention are shown in the drawings, and the Other details not relevant to the present invention. It should be emphasized that the term "including / comprising" when used herein refers to the existence of features, elements, steps or components, but does not exclude the existence or addition of one or more other features, elements, steps or components.

[0033] Here, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com