led light source assembly system

A technology of LED light source and assembly system, applied in the direction of light source, lighting device, transportation and packaging, etc., can solve the problems of manual assembly, complex structure of light guide column, low production efficiency, etc., to improve production efficiency, reduce production cost, and reduce labor the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

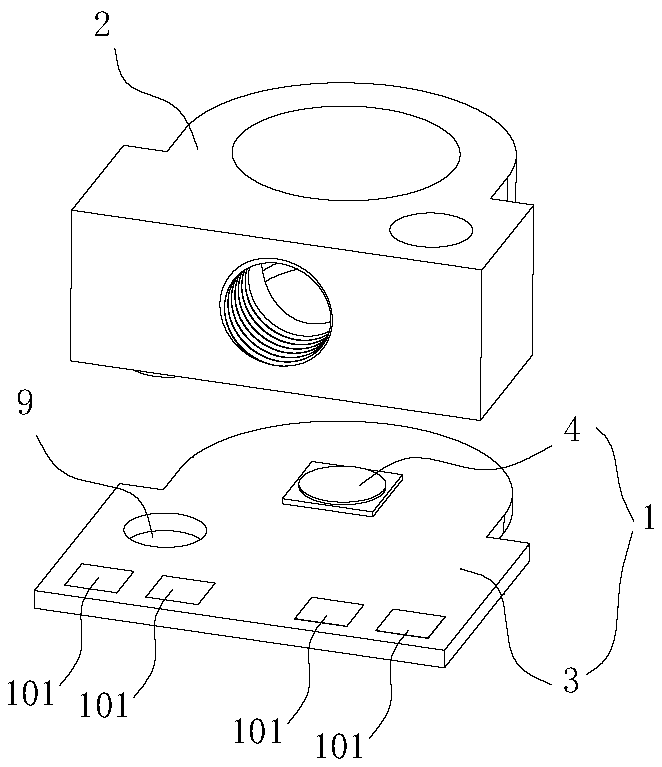

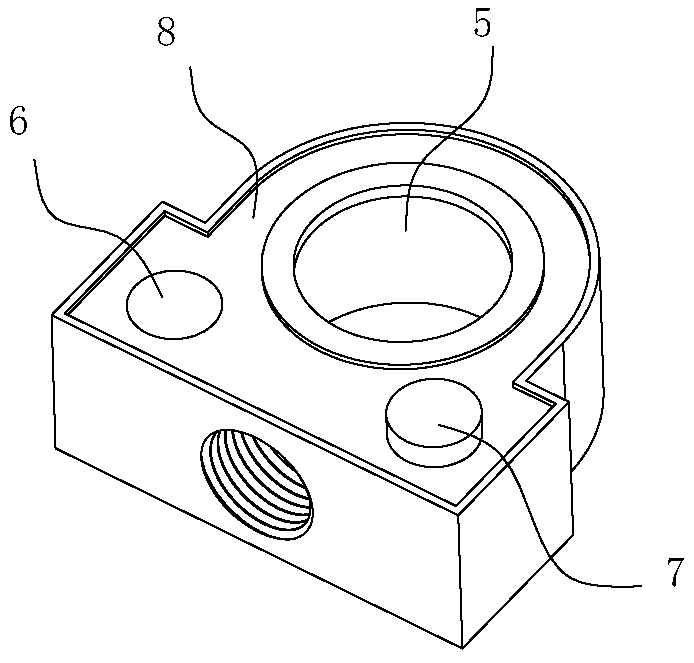

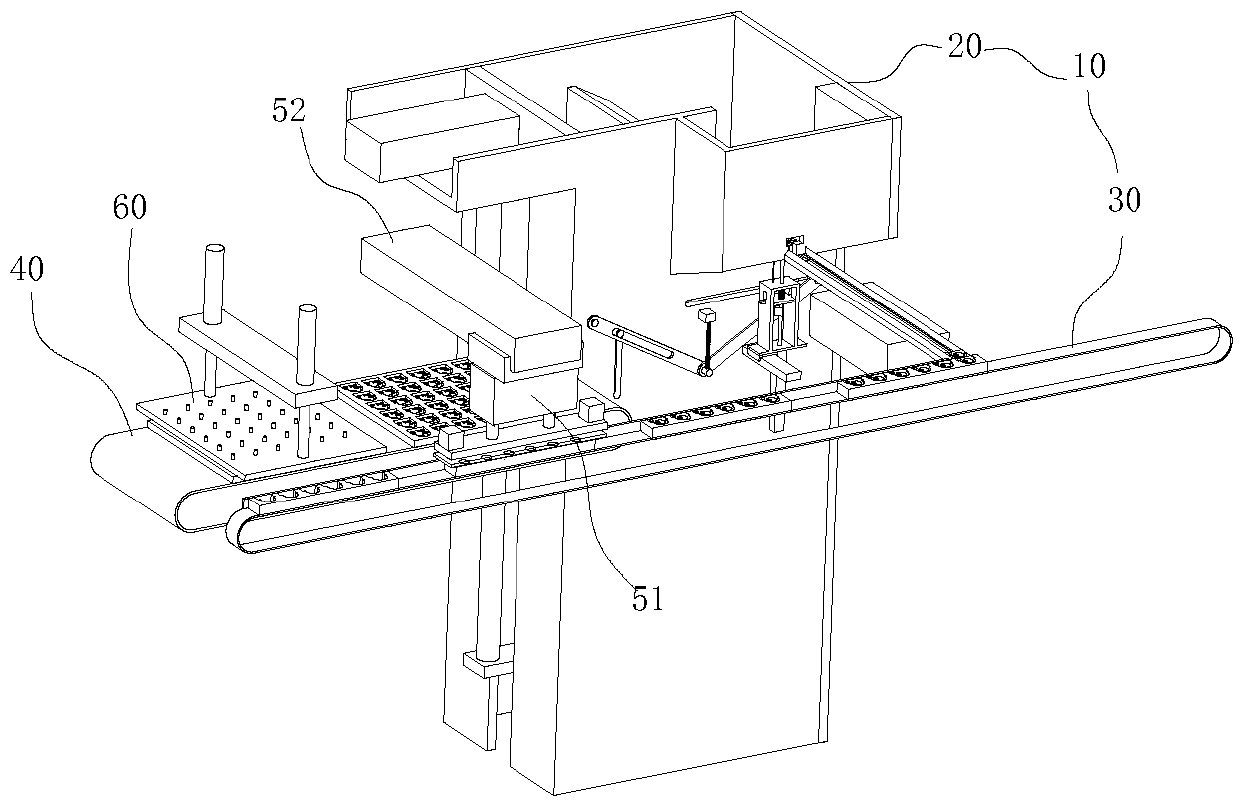

[0047] Such as Figure 3-20 As shown, an LED light source assembly system is used to assemble the LED light guide column 2 and the LED light board 1 into one body. The LED light guide column 2 includes a T-shaped body, and the end surface of the T-shaped body is provided with a through T-shaped The light guide hole 5 and the connection hole 6 are provided on the body, and the T-shaped body is used to connect the LED light board 1 on one side end surface with a positioning post 7 and a glue injection groove 8. The LED light board 1 includes a circuit board 3 and the lamp bead 4, the shape of the circuit board 3 is consistent with the shape of the end face of the LED light guide column 2, the lamp bead 4 is set corresponding to the light guide hole 5 on the LED light guide column 2, and the circuit board 3 is provided with a positioning protrusion 7 corresponds to the assembly hole 9, one side of the circuit board 3 protrudes from the side of the LED light guide column 2, and th...

Embodiment 2

[0058] A method for assembling an LED light source, comprising the steps of:

[0059] Step 1: Prepare the LED light guide column 2 and the LED light board 1, the LED light guide column 2 is injection molded by an injection molding machine, and the LED light board 1 is assembled by a placement machine;

[0060] Step 2: Add the LED light guide column 2 to the LED light guide column fabric conveying module 10, and place the LED lamp board 1 on the LED lamp board conveying module 40;

[0061] Step 3: Arranging the LED light guide columns 2 into a neat array by using the LED light guide column fabric delivery module 10;

[0062] Step 4: Use the assembly module 50 to transfer the array of LED light guide columns 2 arranged in step 3 to the LED lamp board delivery module 40 and fasten it with the LED lamp board 1;

[0063] Step 5: Use the glue injection module 60 to inject heat-conducting glue into the interlayer between the LED light guide column 2 and the LED light board 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com