Christmas tree oil nozzle reading device and system

A reading device and Christmas tree technology, applied in the direction of using electrical devices, mechanical devices, measuring devices, etc., can solve the problems of large reading errors, inability to monitor online, errors, etc., and achieve on-site indications and on-site readings Accurate, measurement accuracy And high reliability, realize the effect of real-time online monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

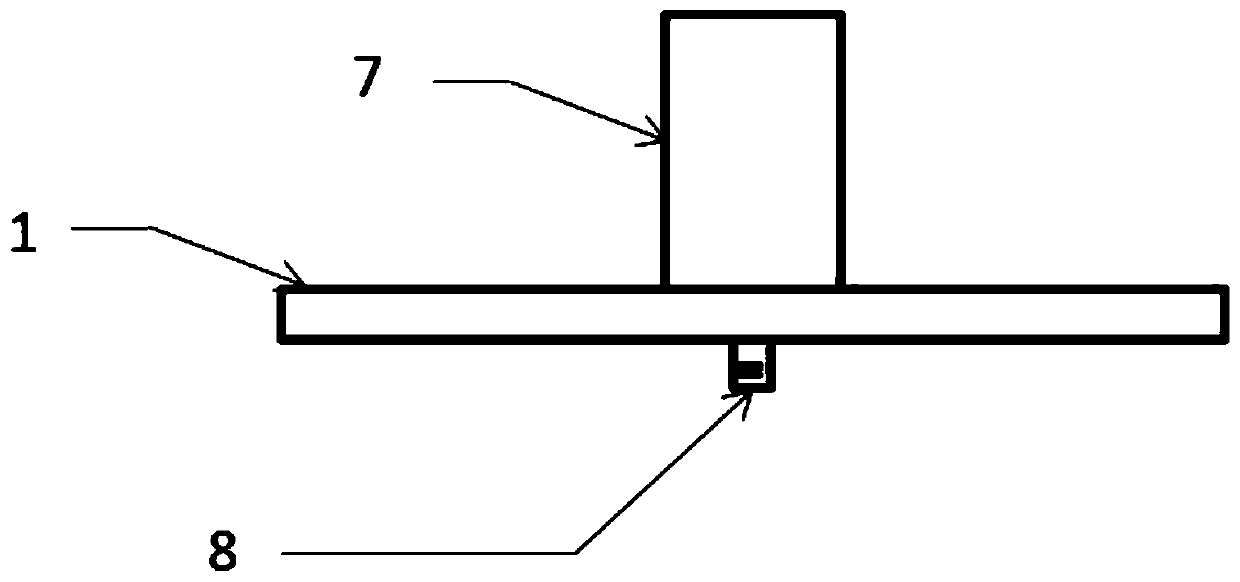

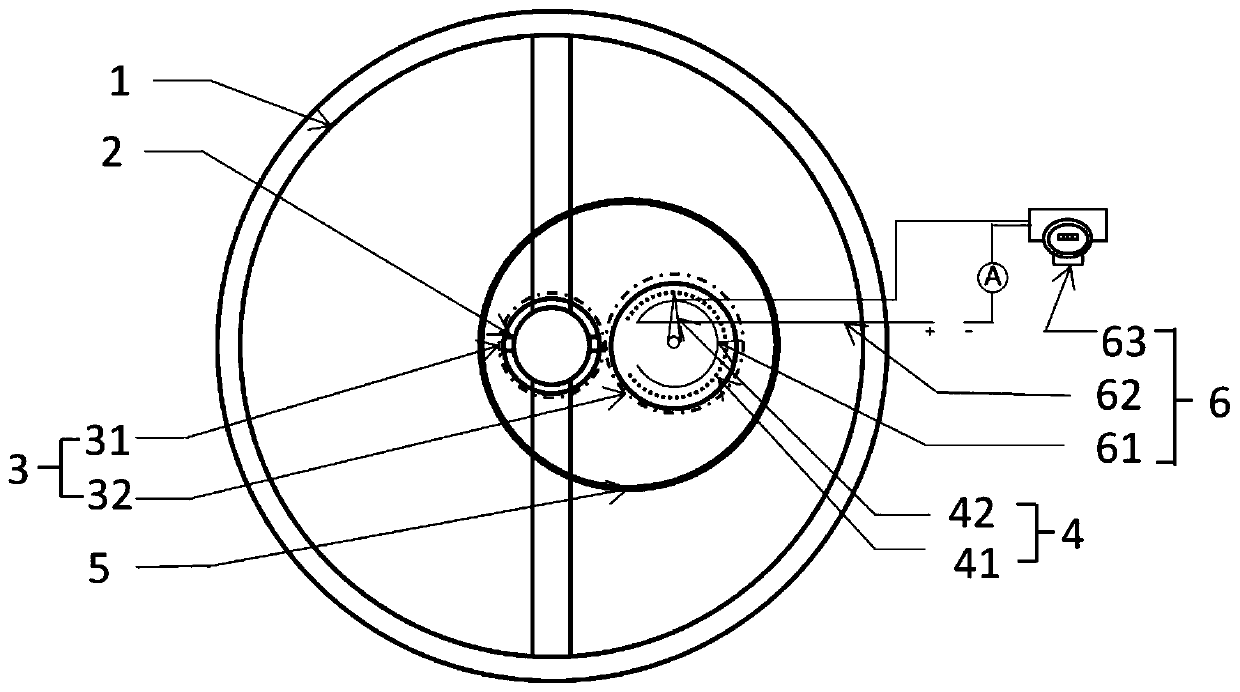

[0031] The first embodiment, such as figure 2 As shown, the present invention constructs a christmas tree nozzle reading device, the nozzle includes a valve handwheel 1, the nozzle reading device includes a fixing device 2 fixed to the valve handwheel 1, a transmission device 3 connected with the fixing device 2, and The on-site display device 4 connected to the transmission device 3 and the supporting device 5 for supporting the transmission device 3 and the on-site display device 4 . Wherein, the rotation of the valve handwheel 1 can drive the transmission device 3 to rotate through the fixing device 2, and then drive the on-site display device 4 to display the rotation scale of the valve handwheel 1. What needs to be explained here is that the scale of the handwheel rotation is the grease nipple scale.

[0032] In this embodiment, the fixing device 2 includes a fixing clip, which is fixedly connected or detachably connected with the valve handwheel 1 and the reading devic...

no. 2 example

[0038] In the second embodiment, on the basis of the first embodiment, the present invention also designs a signal transmission device 6 connected to the on-site display device 4, the signal transmission device 6 is used to convert the scale of the valve handwheel 1 rotation into an analog signal, and send it out.

[0039]Wherein, the signal transmission device 6 includes: a resistance wire 61 , a transmitter 63 , and a power cord 62 for providing power to the transmitter 63 . The resistance wire 61 is set on the dial 41 along the scale value, and the resistance wire 61 corresponding to the zero scale value is connected to the transmitter 63 through the power line 62; the pointer 42 is connected to the transmitter 63 through the power line 62, and the driven gear When 32 drives the pointer 42 to rotate, it can move on the resistance wire 61, convert it into current and transmit it to the transmitter 63. In some embodiments, the resistance wire 61 may be a ring-shaped resistan...

no. 3 example

[0042] In the third embodiment, the present invention also constructs a christmas tree oil nozzle reading system, including the above-mentioned christmas tree oil nozzle reading device, and a remote control system connected with the christmas tree oil nozzle reading device, which will not be repeated here.

[0043] By implementing the present invention, there are following beneficial effects:

[0044] The christmas tree oil nozzle reading device of the present invention is designed with a fixing device fixed on the valve handwheel, a transmission device connected with the fixing device, an on-site display device connected with the transmission device, and a supporting device for supporting the transmission device and the on-site display device . Among them, when the valve handwheel rotates, the fixing device can drive the transmission device to rotate, and then drive the on-site display device to display the scale of the valve handwheel rotation, which has high measurement acc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap