Steel shell and concrete combined structure member thermodynamic coupling loading test device and method

A technology of loading test device and combined structure, which is applied in the direction of measuring device, using stable tension/pressure to test material strength, material thermal analysis, etc., and can solve the problems of lack of research foundation for mechanical behavior and functional characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

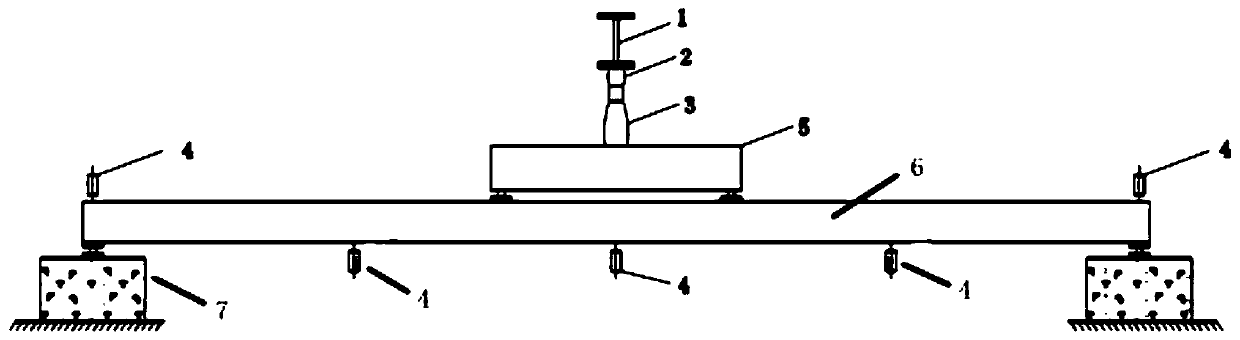

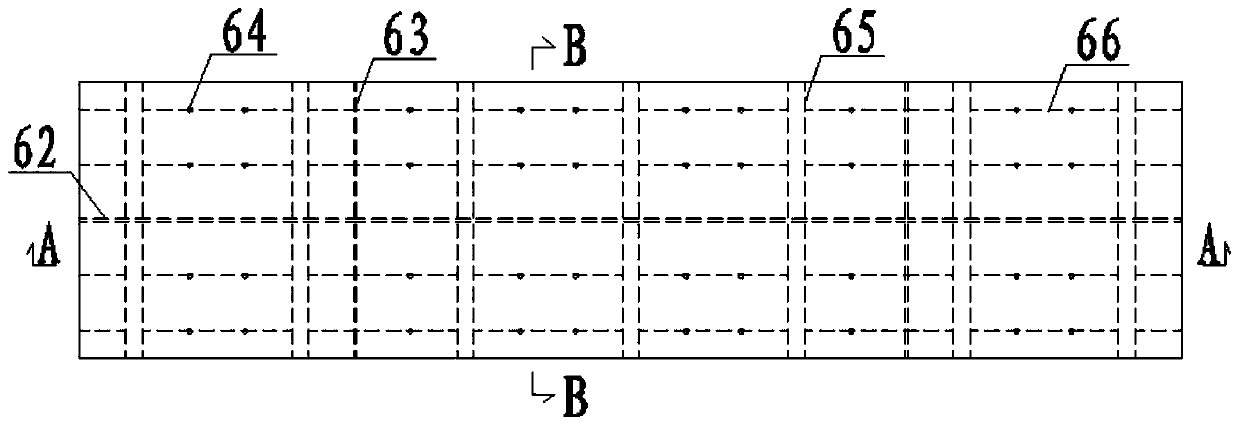

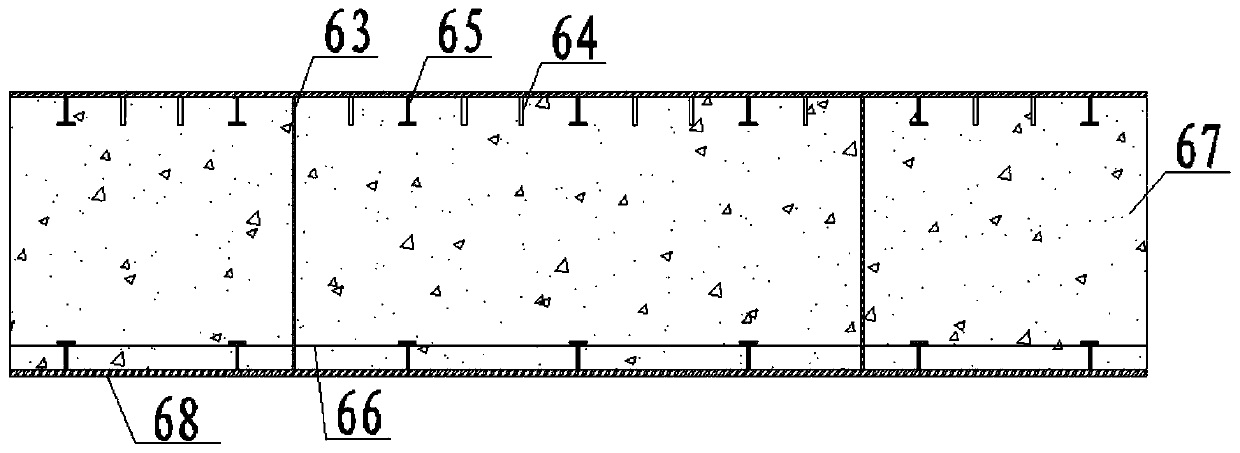

[0043] Embodiment: This embodiment constructs a model of a test member, which reflects the geometric, structural and mechanical characteristics of the steel shell concrete structure. Therefore, the section type of the member is determined first, and then the span of the member is determined, and then the size of the test member is determined. Such as Figure 2-4 As shown, the total length of the test member is 2m, the beam height is 0.5m, and the width is 0.5m. The thickness of the inner and outer steel plates (namely the steel shell) of the component is 10mm, the steel is Q420B, the thickness of the horizontal and vertical partitions is 4mm, the steel is Q390B, and the rest of the steel is Q345B. The distance between the diaphragms is 1m, and the concrete strength is C50. First, cut each piece of steel plate according to the size requirements, draw the positioning line of the welding stud on the steel plate, and weld the welding stud of the specified size on the correspondin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com