One-piece insulating column of motor

An insulating column and conjoined technology, used in electrical components, electromechanical devices, electric components, etc., can solve the problems of low production efficiency, coil solder joints falling off, easy damage, etc., to prevent excessive coil winding and prevent coil welding. The effect of point falling off and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, achievement goals and effects of the novel implementation of the present invention easy to understand and understand, the present invention is further described below with reference to the specific embodiments.

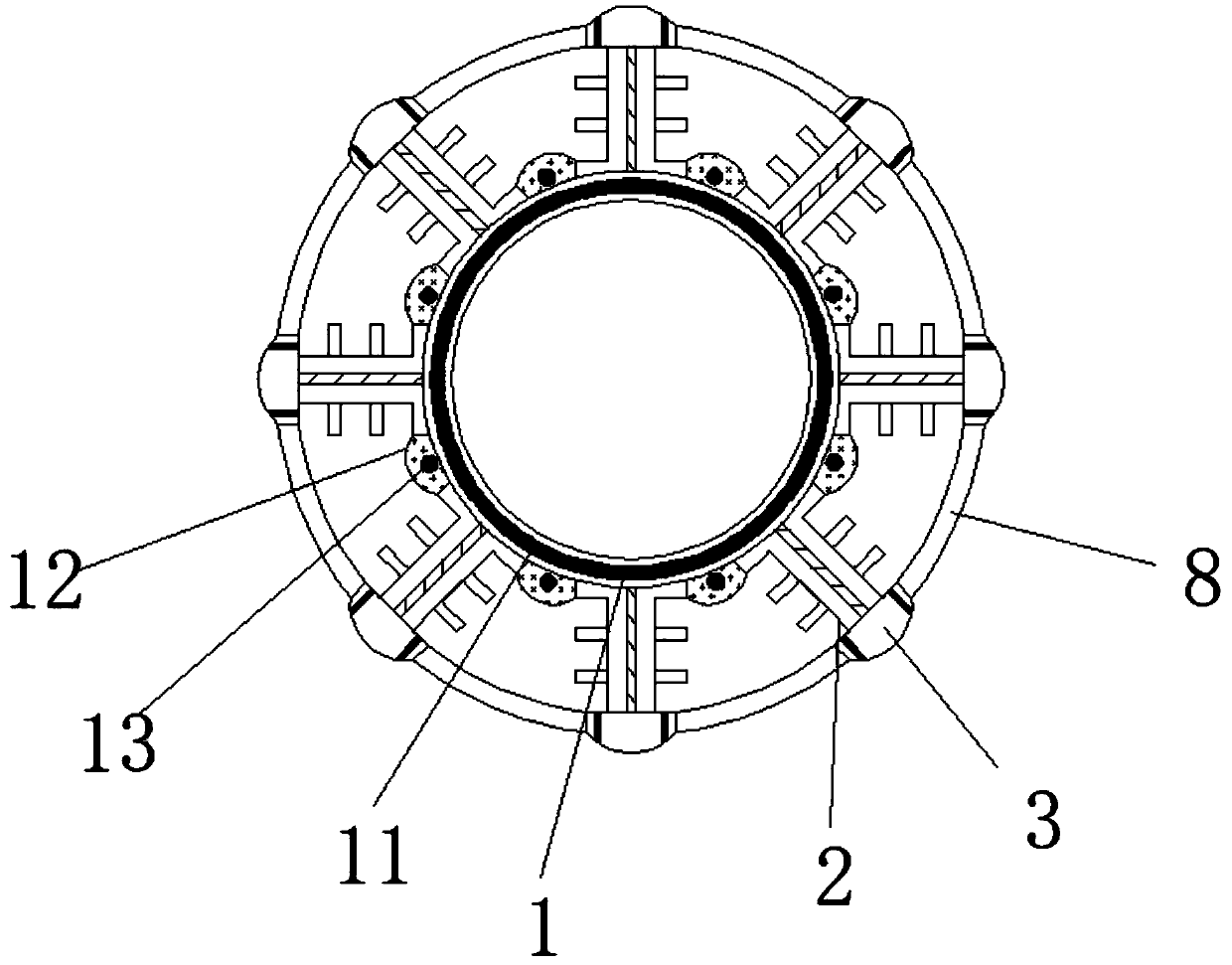

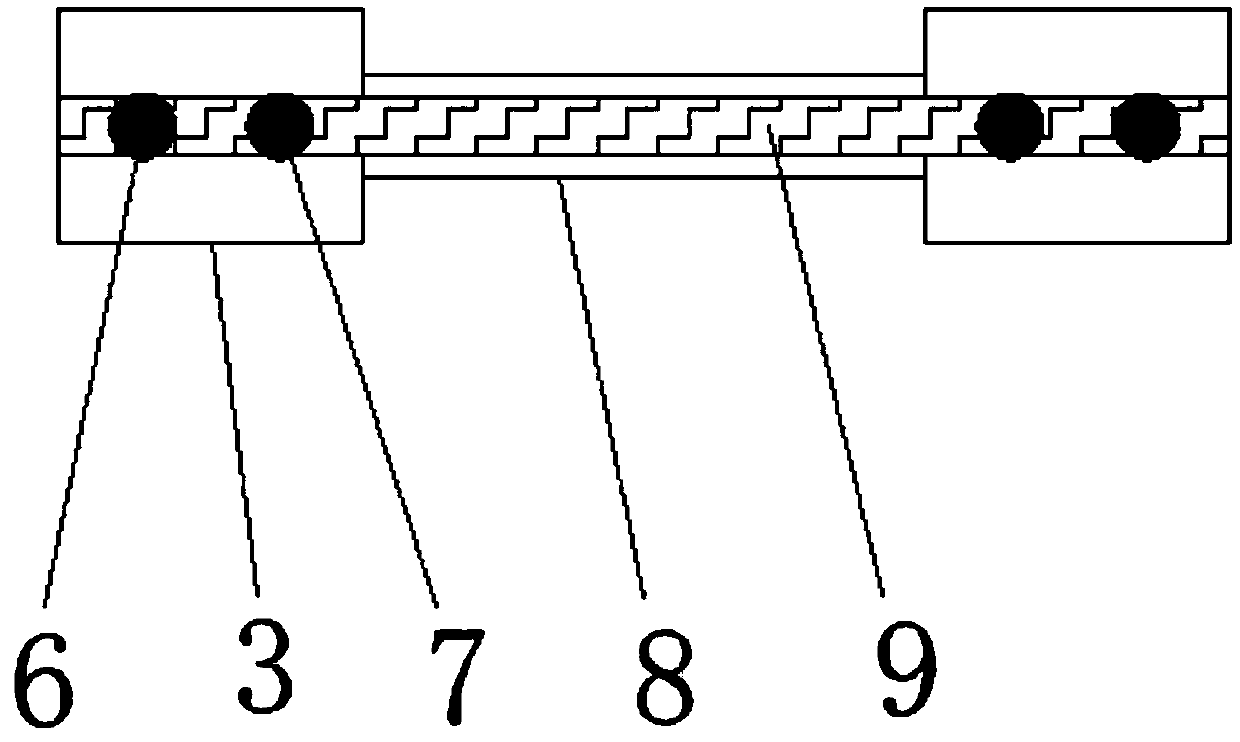

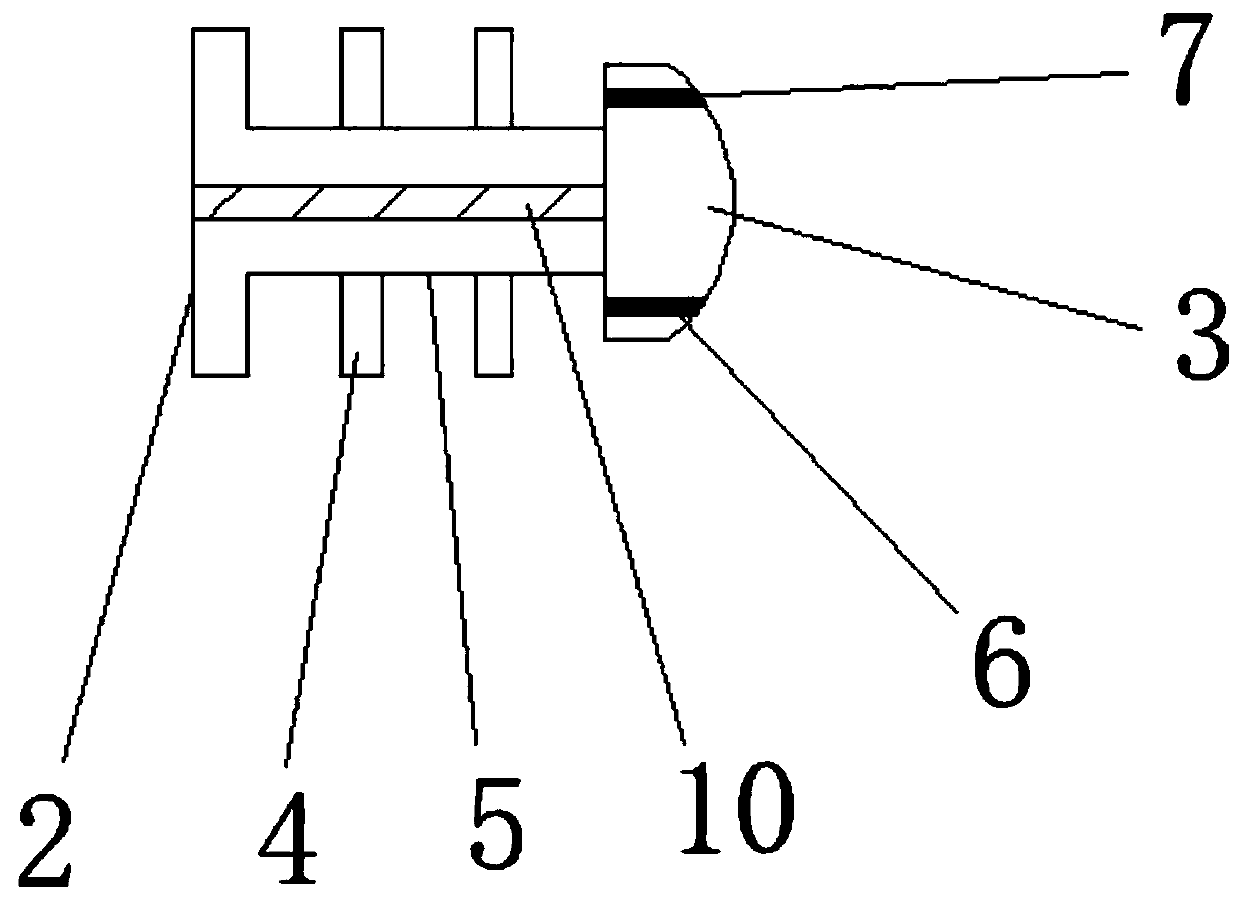

[0022] like Figure 1-3 As shown, a motor conjoined insulating column includes an insulating column inner sleeve 1, a winding column 2 and a stopper 3. A winding column 2 is fixedly connected to one side of the outer wall of the insulating column inner sleeve 1, and the winding column 2 is specifically provided with Several groups, one end of the winding column 2 is fixedly connected with a stopper 3, both sides of the winding column 2 are fixedly connected with side wings 4, and the side wings 4 are specifically provided with several groups, and the surface of the stopper 3 is provided with incoming wires. Hole 6, one side of the wire inlet hole 6 is provided with a wire outlet hole 7, one side of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com