Dust removal device for new energy automotive component cutting

A technology of new energy vehicles and dust removal devices, which is applied in the direction of combined devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems that dust cannot be handled conveniently and effectively, the dust removal device has a single exhaust device, and the range of dust removal is not easy to control. To achieve the effect of improving convenience and functionality, improving the effect, and improving the effect of dust filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

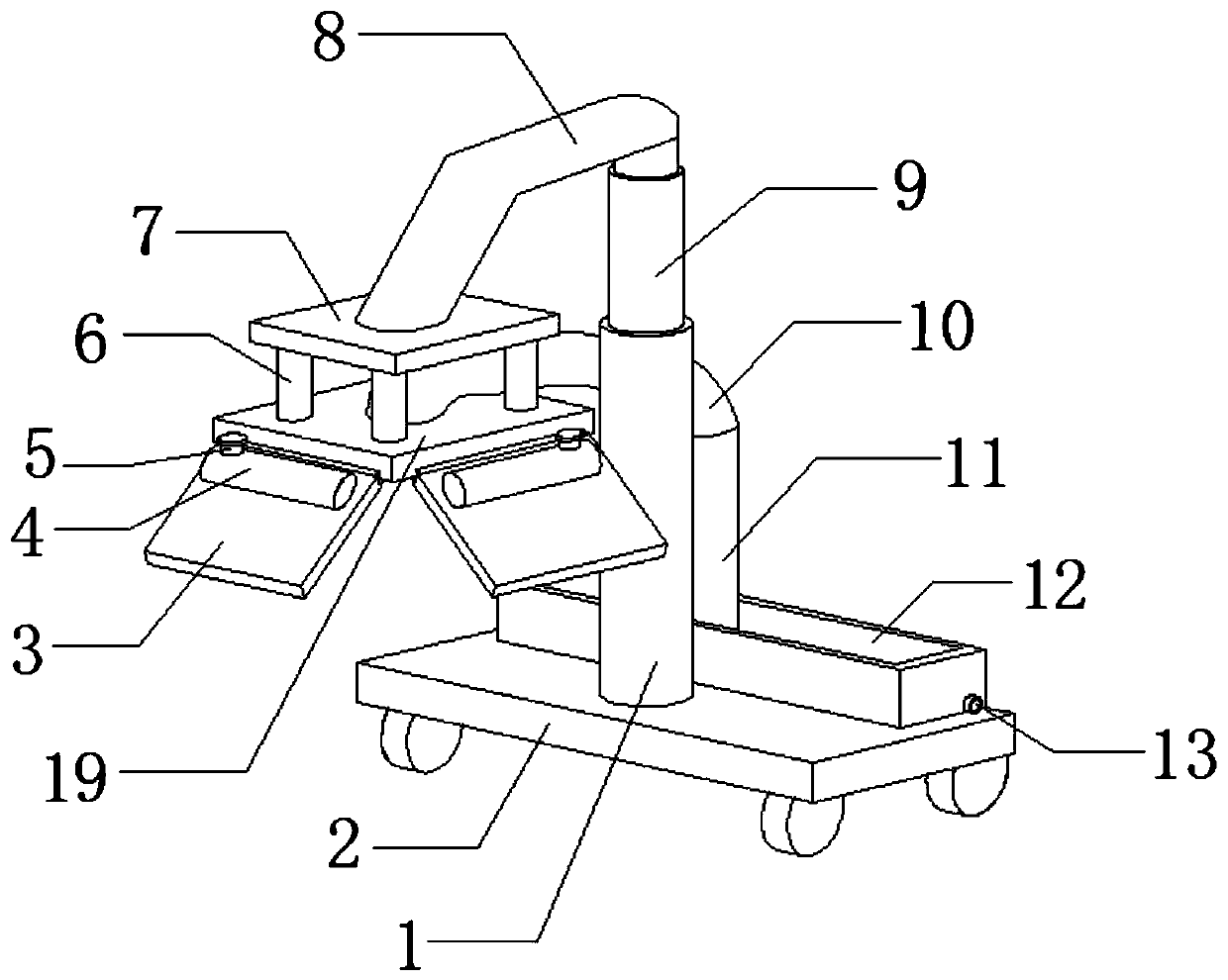

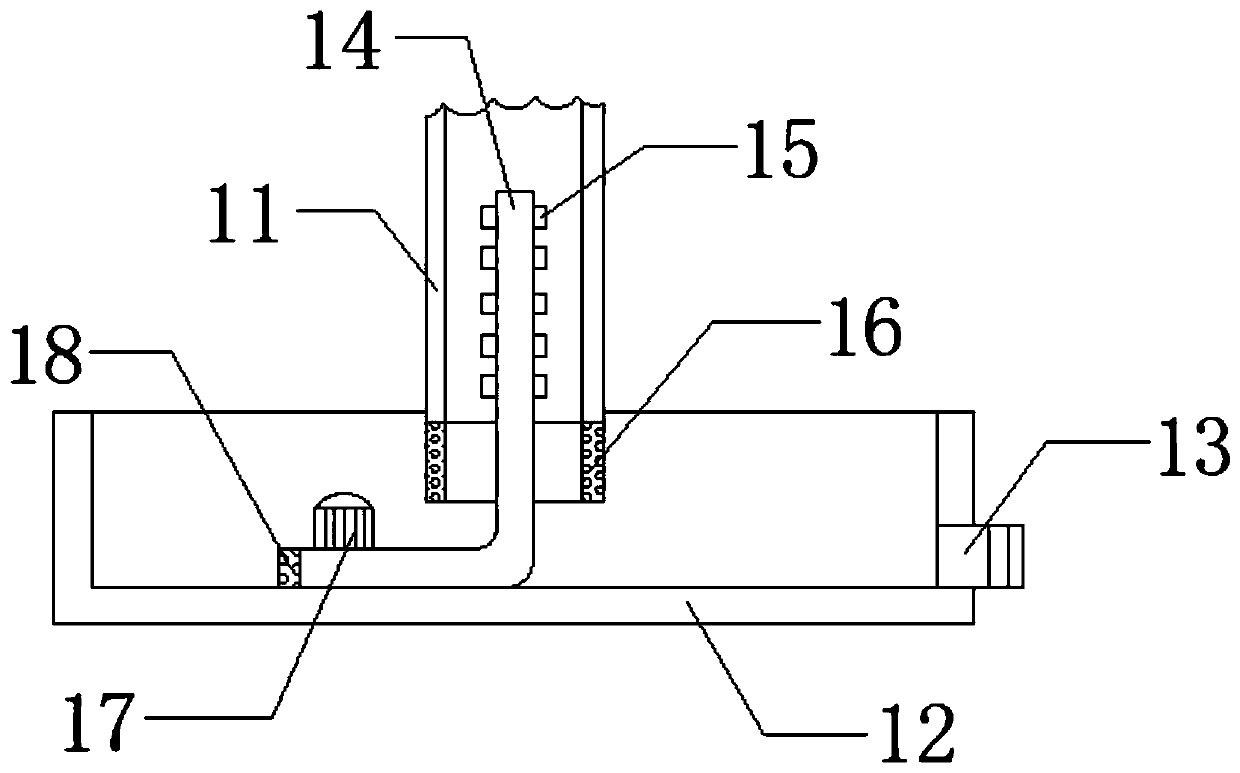

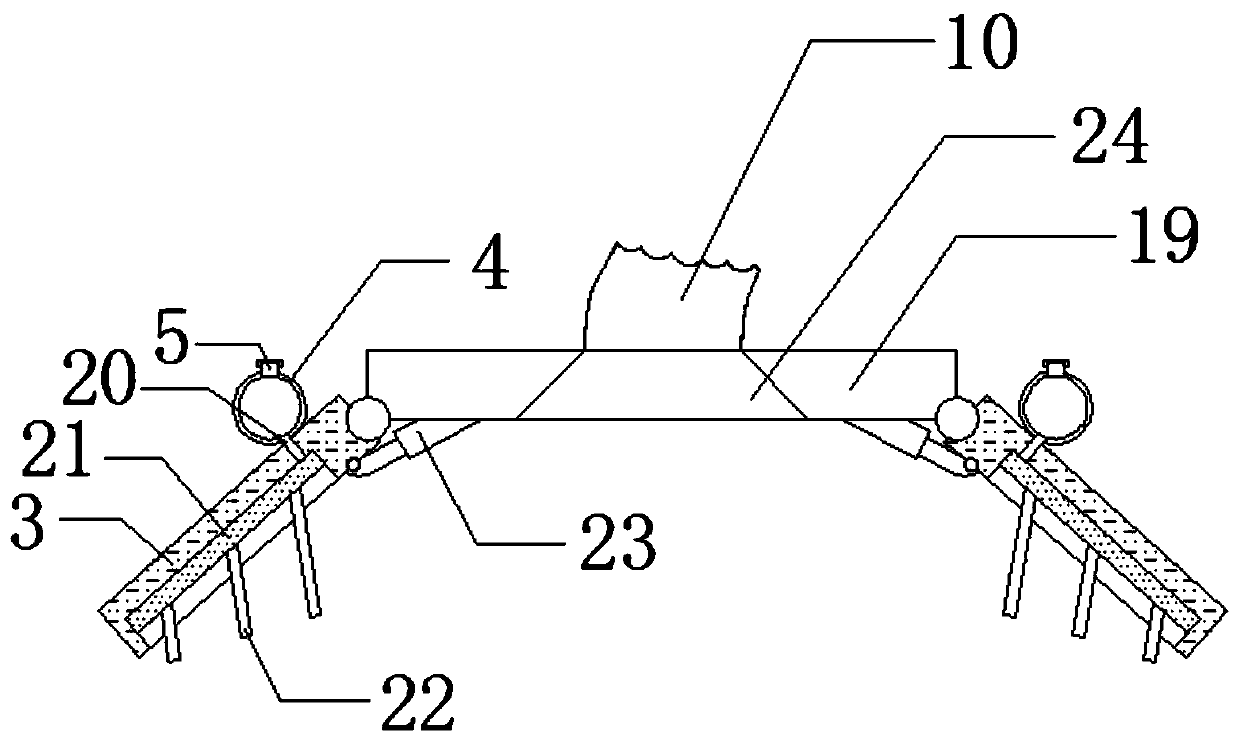

[0029] refer to Figure 1-3 , a dust removal device for cutting new energy automobile parts, including a support base plate 2 and a second support plate 19, the outer walls around the second support plate 19 are connected with a first support plate 3 through hinges, and four first support plates The top outer wall of the water storage pipe 4 is connected with the water storage pipe 4 by bolts, the bottom outer wall of the water storage pipe 4 is connected with the second aqueduct 20 by bolts, and the top side outer wall of the water storage pipe 4 is connected with the water inlet pipe 5 by bolts. And the top outer wall of the circumference of the water inlet pipe 5 is threadedly connected with the water inlet pipe cover, the bottom outer walls of the four first support plates 3 are provided with first grooves, and the top inner walls of the first grooves are all connected with cloth pads by bolts. 21. The inner walls on both sides of the four first grooves are connected with ...

Embodiment 2

[0034] refer to Figure 1-4 , a dust removal device for cutting new energy automobile parts, further comprising a mounting groove opened on the outer wall on the other side of the bottom of the support base plate 2, and the inner wall of the mounting groove is connected with a counterweight 25 by bolts.

[0035] When in use, the counterweight 25 can effectively balance the force on the other side of the device, improve the stability of the device in use, and prevent the device from toppling over.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com