A hot plate mold for lamp manufacturing

A mold and hot plate technology, applied in the field of hot plate molds, to achieve the effect of easy replacement, avoiding manpower, and facilitating replacement work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

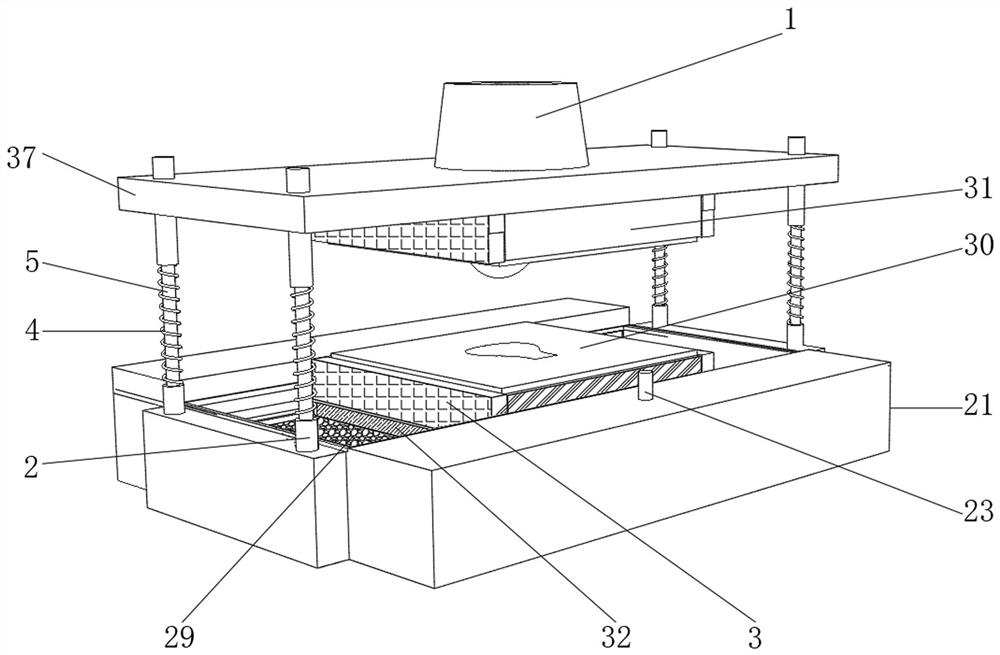

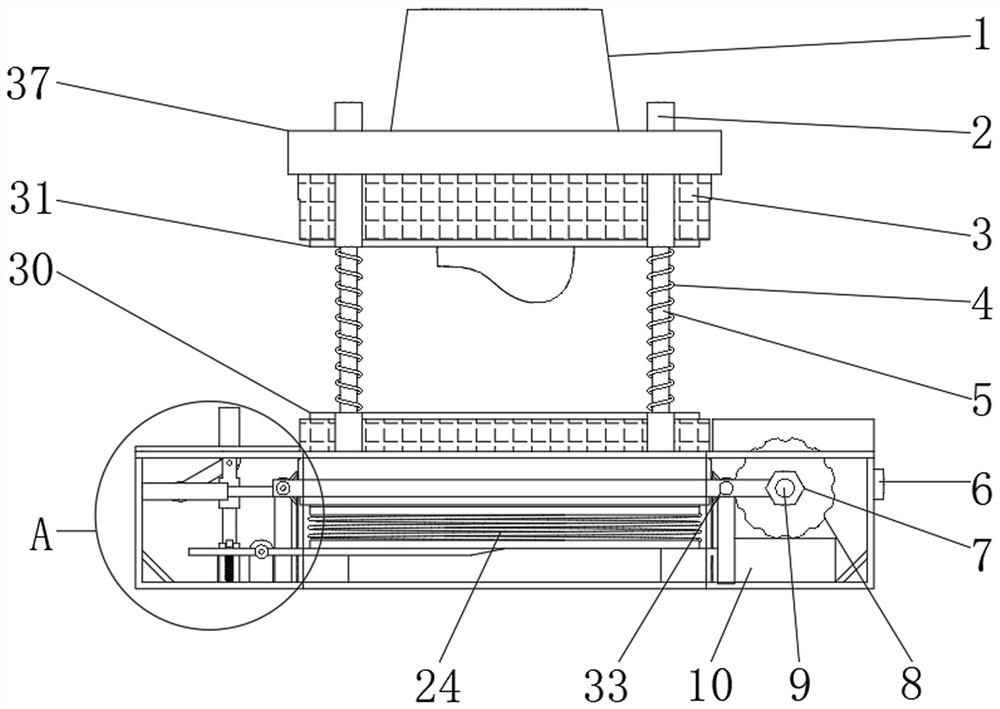

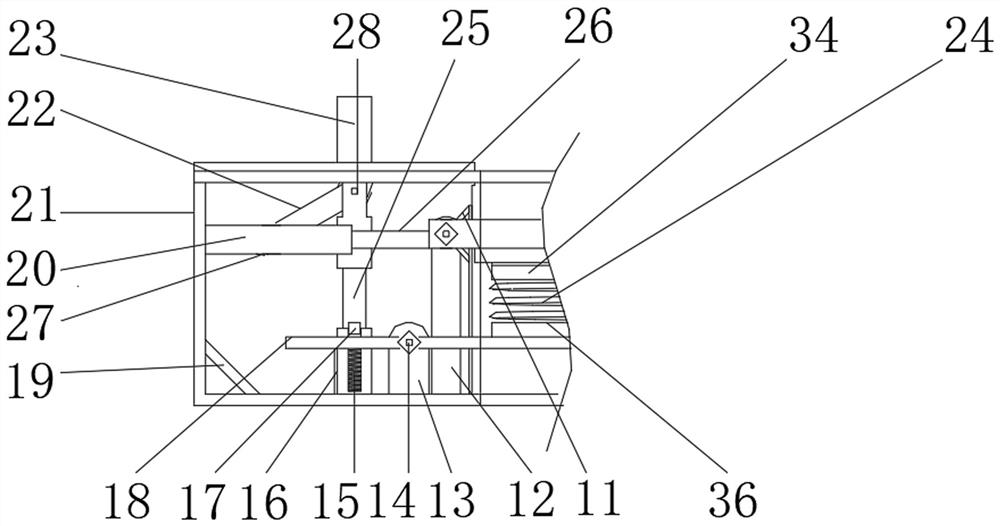

[0032] refer to Figure 1-6 , a hot plate mold for the manufacture of lamps, including a housing 21, the upper surface of the housing 21 has an installation opening, and the upper surface of the installation opening is fixed with a sliding rail 29 by bolts, and the inner four walls of the housing 21 are welded with support Frame 19, both sides of the inner wall of sliding rail 29 are all fixed with heat insulation boards by bolts, and the bottom of the inner wall of housing 21 is fixed with support plate 10 by bolts, and the upper surface of support plate 10 is fixed with motor 8 by bolts, and the two sides of the upper surface of housing 21 The first support column 2 is welded on both sides, the first support column 2 is plugged with the first slide bar 5, and one end of the first slide bar 5 is plugged with the second support column, and one side of the outer wall of the second support column is welded There is the same top plate 37, the upper surface of the top plate 37 is ...

Embodiment 2

[0036]refer to Figure 7 , a hot plate mold for the manufacture of lamps, including a top plate 3, both sides of the bottom of the top plate 37 are fixed with a lampshade 38 by bolts, and one end of the inner wall of the lampshade 38 is threadedly connected with an energy-saving lamp 39, through the setting of the energy-saving lamp 39 can be installed Watch the production situation more clearly when working, and be more careful when repairing or replacing equipment. There are multiple hinges fixed on the four sides of the upper surface of the housing 21 by bolts, and a transparent protective plate 35 is fixed on one end of the hinge by bolts. The setting of the transparent protection 35 can avoid the danger of parts splashing out when the machine is working, and at the same time, the operating condition of the equipment can be observed.

[0037] The working principle of this embodiment: when in use, when the mold is running at night or when parts are replaced and maintained, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com