Hybrid excitation wound rotor and hybrid excitation wound synchronous motor

A hybrid excitation and winding rotor technology, applied to synchronous motors with stationary armatures and rotating magnets, synchronous machines, synchronous machine parts, etc., can solve the problem that the torque component cannot be fully utilized, and achieve improved torque Effects of output, improved torque density, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

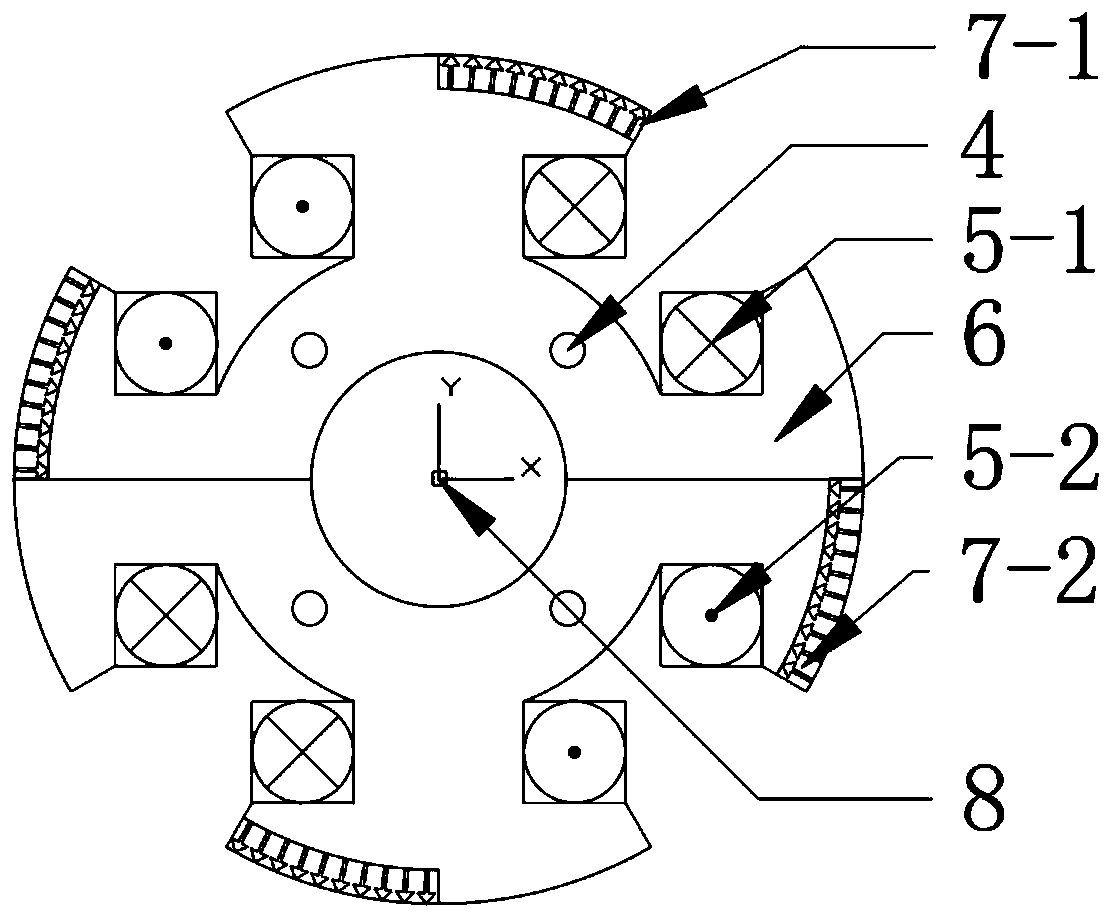

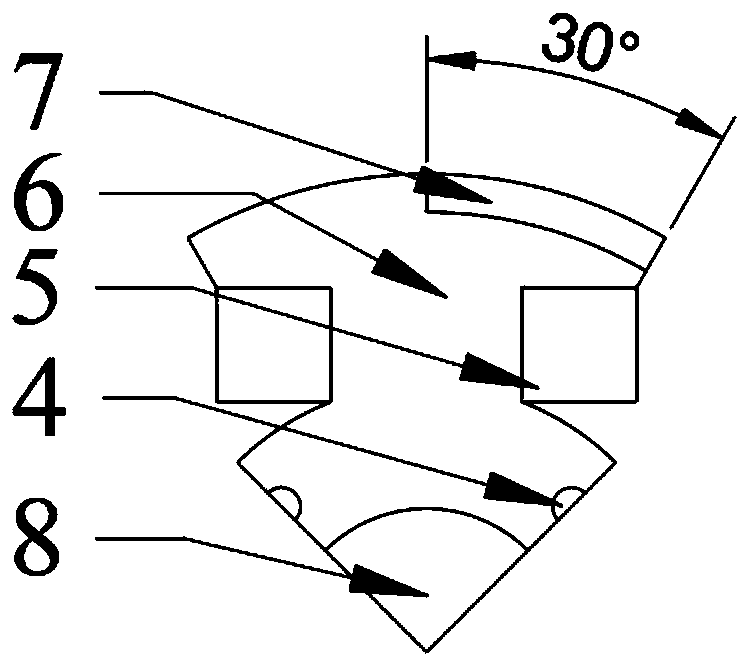

[0031] In one or more embodiments, a hybrid excitation wound rotor is disclosed, which is applied to a wound permanent magnet motor. The rotor includes a rotating shaft 8, a rotor core 6 fixed on the rotating shaft 8, and a rotor core 6 on the rotor core 6. Winding coils, and permanent magnets 7 installed at the ends of the salient poles of the rotor. A set of winding coils is installed on each salient pole to generate rotor magnetomotive force. A piece of tile-shaped permanent magnet 7 is installed along the opposite side of the rotation direction of the motor rotor on the geometric center line of each salient pole end, and the permanent magnet 7 makes the rotor asymmetric. The iron core of the rotor part is formed by axially laminating cold-rolled silicon steel sheets. The winding on the rotor core 6 is connected to the DC power supply through the brush slip ring, and the current passes through the winding to generate the rotor magnetomotive force.

[0032] The motor part ...

Embodiment 2

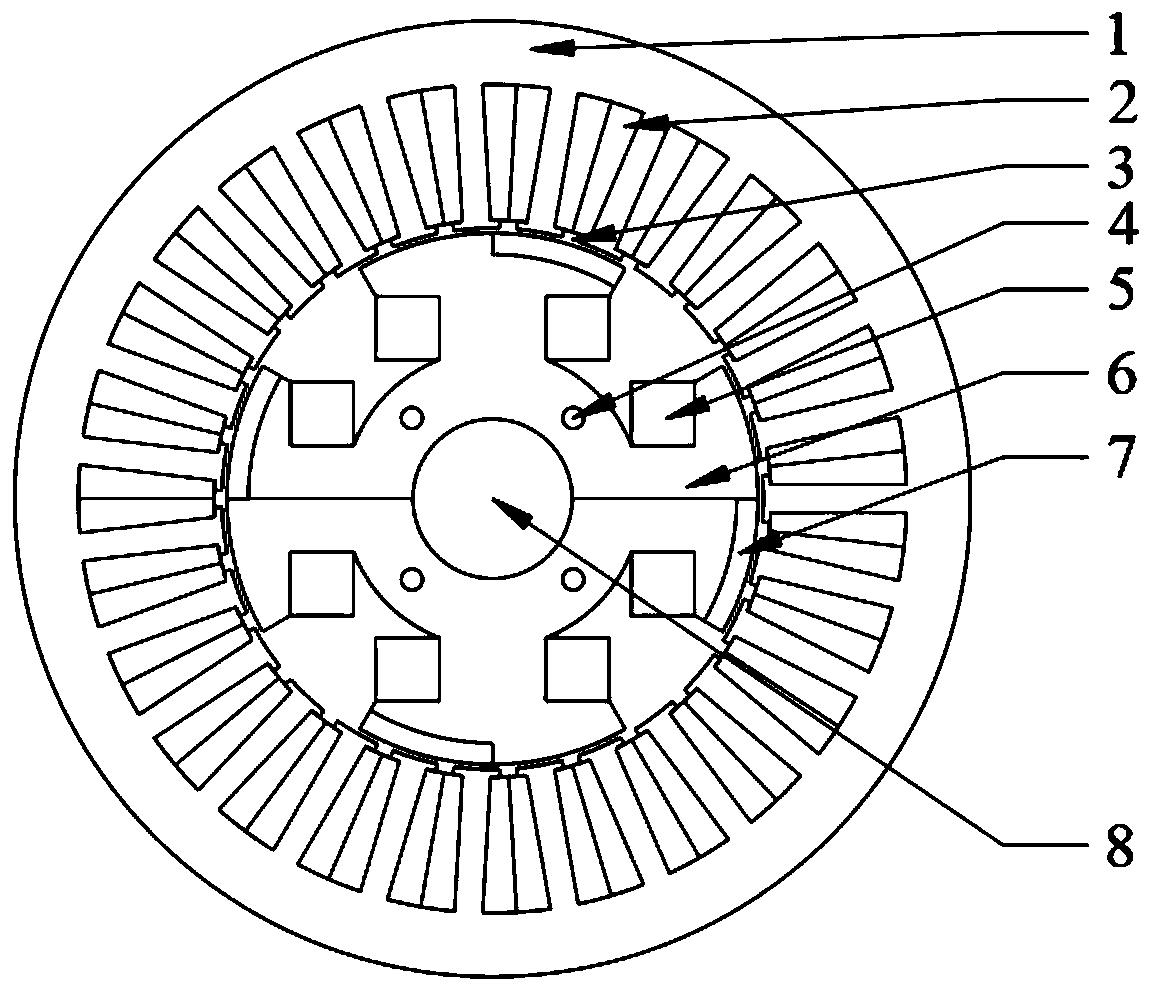

[0040]In one or more embodiments, a hybrid excitation wound synchronous motor is disclosed, referring to figure 1 , The high-performance hybrid excitation wound synchronous motor has a stator part and a rotor part inside the casing.

[0041] Wherein, the rotor part adopts the rotor part structure disclosed in the first embodiment.

[0042] The stator part includes: stator core 1 and stator winding 2. The stator core 1 is formed by laminating silicon steel sheets in the direction of the rotating shaft 8. The silicon steel sheets are thin plates made by adding silicon to iron to reduce eddy current loss. The stator core 1 is cylindrical and extends in the direction of the rotating shaft 8 of the rotating shaft 8 . The stator slots are arranged at equal intervals along the circumferential direction on the inner periphery of the stator, and extend from the stator core 1 side to the rotating shaft 8 in a convex shape. In this embodiment, 27 stator slots are provided, and three-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com