Dough-kneading lifting stirring mechanism

A technology of a stirring mechanism and a lifting mechanism, which is applied to the structural parts of mixing/kneading machinery, and mixing/kneading with vertical installation tools, can solve the problems of limited mixing range, low practical flexibility, etc. Mixing range, high flexibility, easy cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

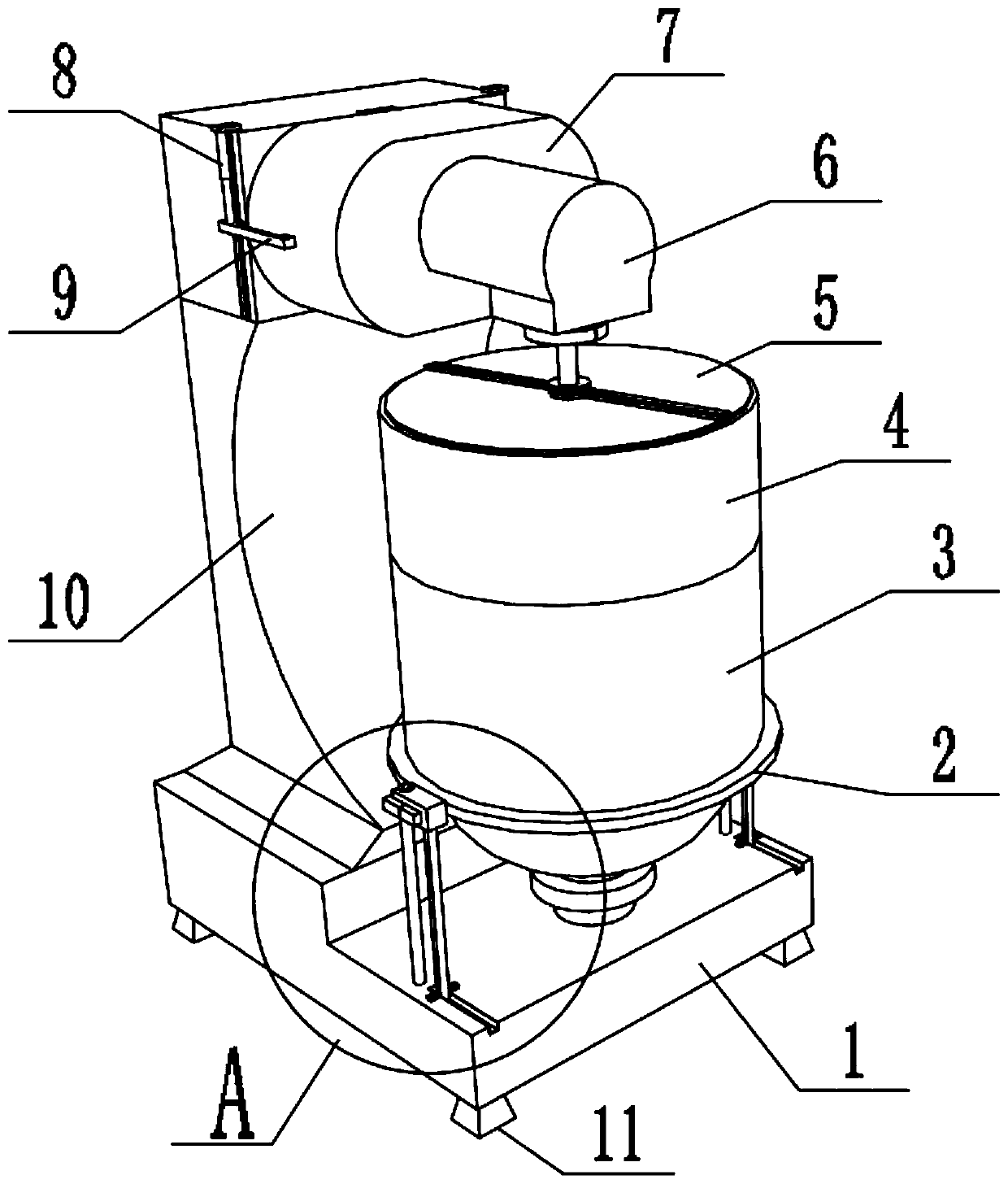

[0032] A lifting and stirring mechanism for kneading noodles, such as Figure 1-5 As shown, it includes a base 1, one side of the top of the base 1 is welded with a support base 10, the top of the support base 10 is connected to the machine head frame 7 by a lifting mechanism, and one side of the machine head frame 7 is welded with the machine head 6, the machine head The bottom end of the head 6 is provided with a stirring assembly, and the top of the base 1 is fixed with a storage tank 3 through a connecting mechanism; the inner wall of the head frame 7 is provided with a motor, and the output shaft of the motor is connected with the stirring assembly through a transmission shaft.

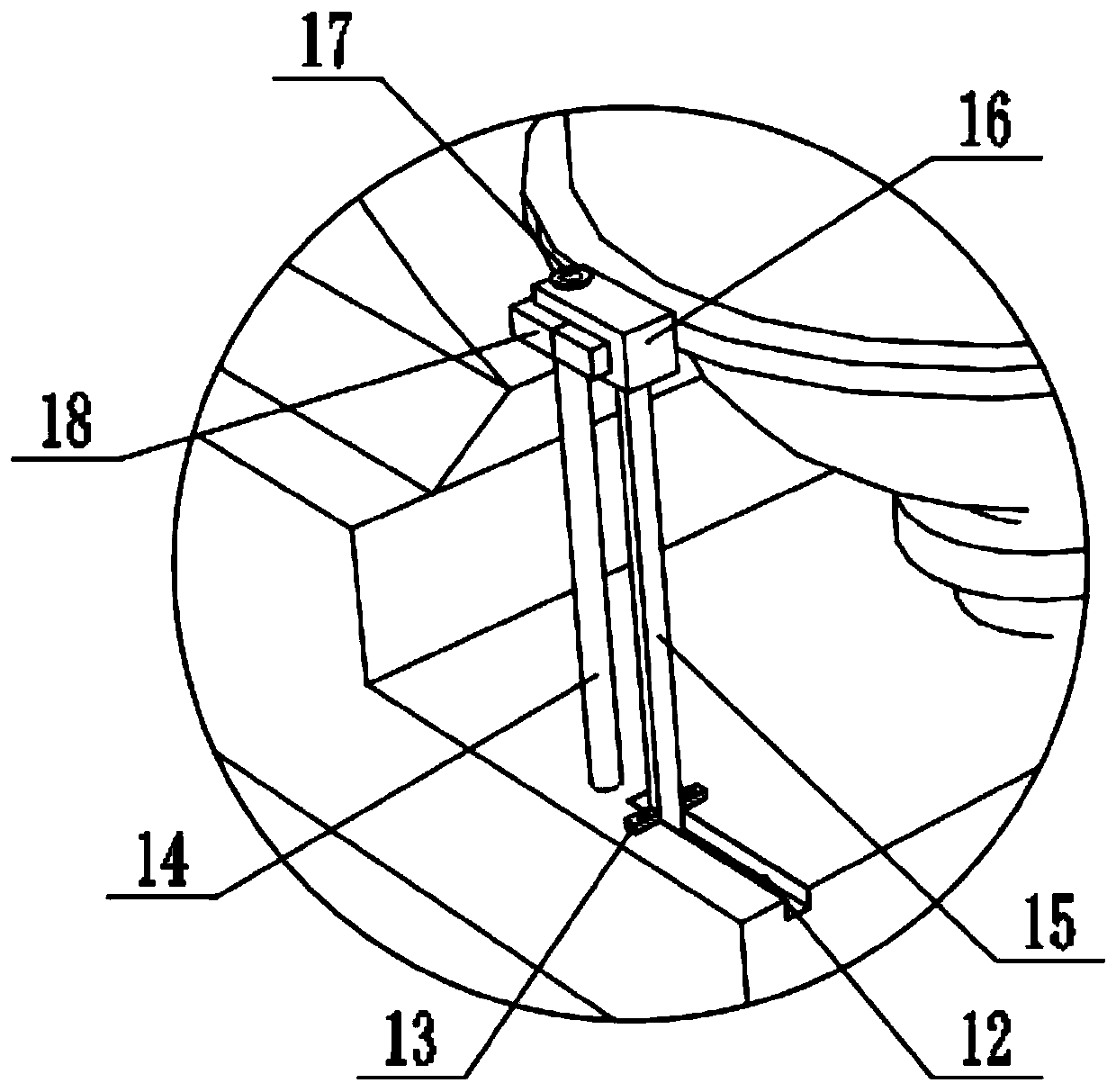

[0033] In order to solve the problem of inconvenient cleaning of the mixing tank; figure 1 and figure 2 As shown, the connecting mechanism includes a fixing hoop 2, a first pole 14 and a second pole 15, the fixing hoop 2 is a structure of two semicircular snap rings, and the side walls of the t...

Embodiment 2

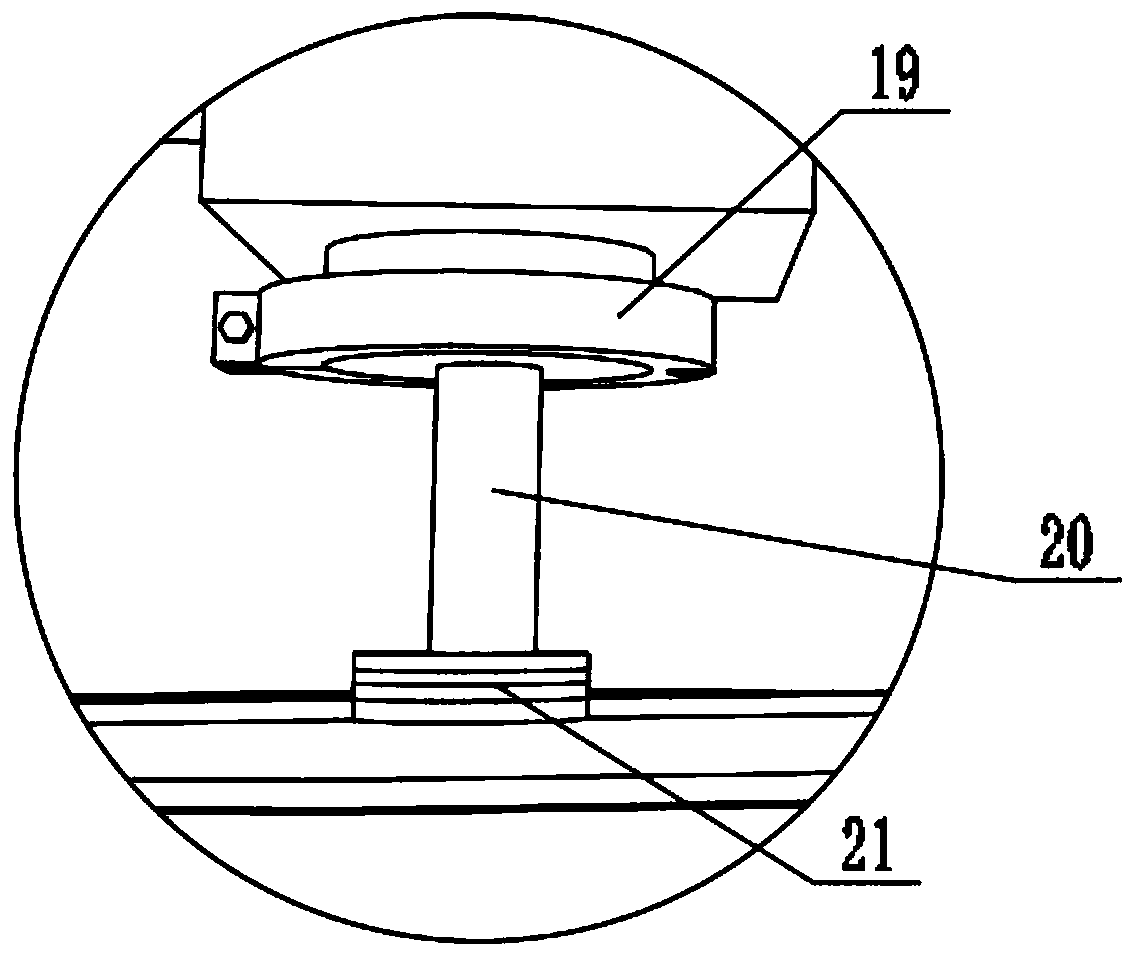

[0040] A kind of dough raising and stirring mechanism, such as figure 1 , image 3 and Figure 5 As shown, in order to solve the problem of flour flying during the stirring process; this embodiment makes the following improvements on the basis of embodiment 1: the top of the storage tank 3 is sleeved with a dust cover 4, and the top of the dust cover 4 is provided with an anti-dust cover. The dust cover 5 and the dust cover 4 are provided with a sealing hoop 21, which can seal the dust cover 4 through the dust cover 5, so as to avoid the phenomenon that the flour splashes out of the storage barrel 3 during the stirring process;

[0041] Wherein, the dustproof cover 5 includes two No. 1 plates 26, the No. 1 plates 26 are semicircular structures, the side walls of one No. 1 plates 26 are welded with raised blocks 28, and the side walls of the other No. 1 plates 26 are opened. There is a raised slot 29, and the raised block 28 is adapted to the raised slot 29; by assembling and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com