Lettering knurling processing process for stainless steel screw

A processing technology, stainless steel technology, applied in the field of stainless steel screw lettering knurling processing technology, can solve the problems of increasing cost, material waste, deficiencies to be improved, etc., to achieve cost saving, increase pass rate, and reduce waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

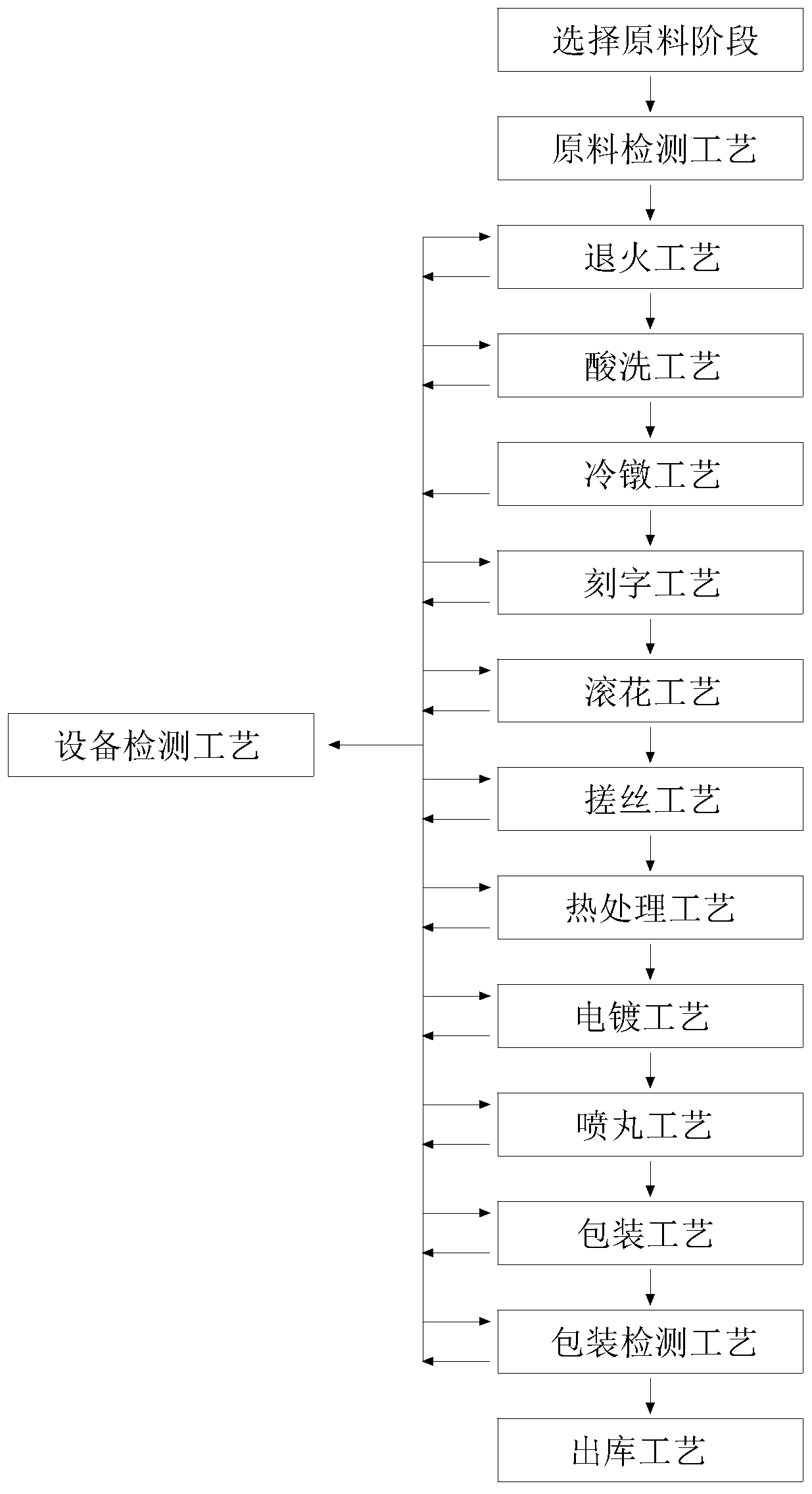

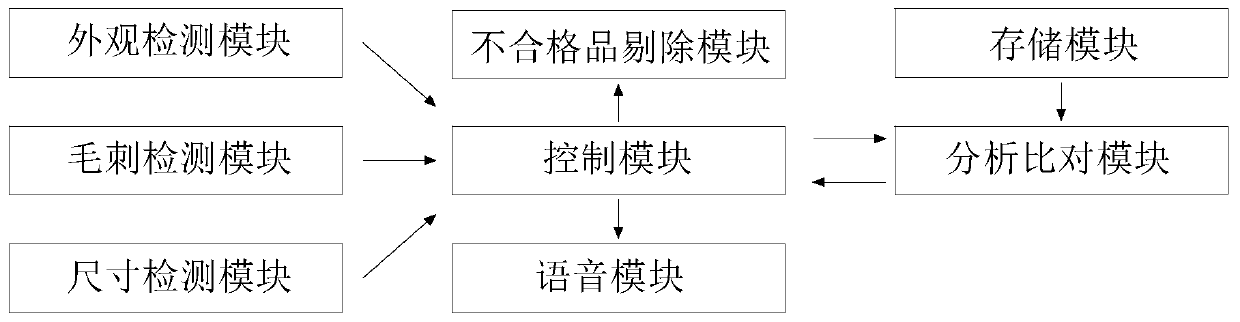

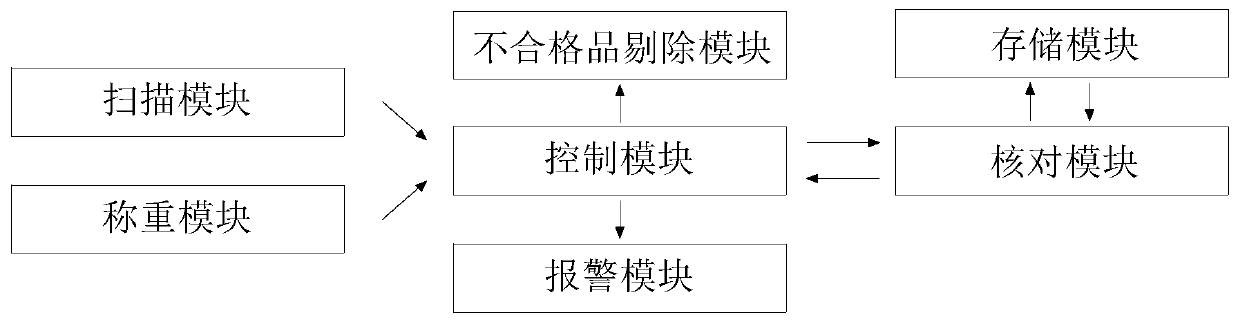

[0021] see Figure 1-4 , the present invention provides the following technical solutions: a stainless steel screw lettering knurling process, comprising the following steps: selecting raw materials: raw materials are stainless steel bars, wherein the components of the stainless steel bars are calculated by mass fraction: Cr: 12% to 17%, C : 0.07~0.16%, Ni: 1.21~1.93%, Ti: 0.28~0.61%, Mn: 0.19~0.2%, N: 0.23~0.48%, Nb: 0.11~0.49%, Mo: 1.12~1.46%, Si: 0.15~0.37%, Cu: 0.6~0.88%, the balance is Fe; Raw material detection: carry out the detection process on stainless steel bars, and when unqualified stainless steel bars are detected, the staff will be alerted and automatically removed; annealing: the stainless steel bars will be Put it in the annealing furnace for annealing process; pickling: pickling the stainless steel bar to remove the oxide film on the surface of the stainless steel bar; cold heading: cut the stainless steel bar, pier it into a stainless steel screw blank; The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com