Kitchen garbage classifying device

A sorting device and kitchen waste technology, applied in trash cans, garbage collection, household appliances, etc., can solve the problems of time and manpower consumption, reduced lunch break time, error-prone, etc., and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

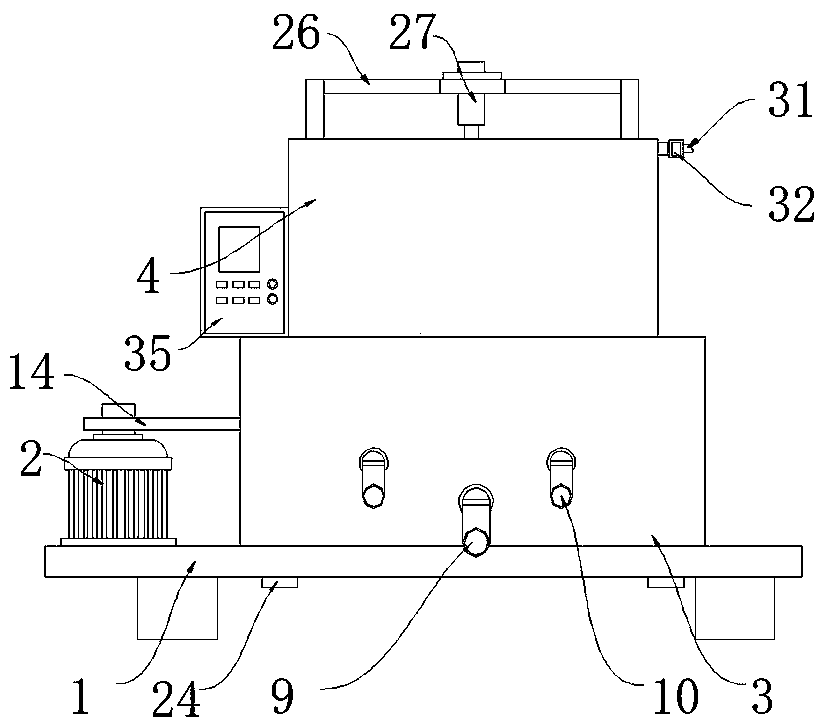

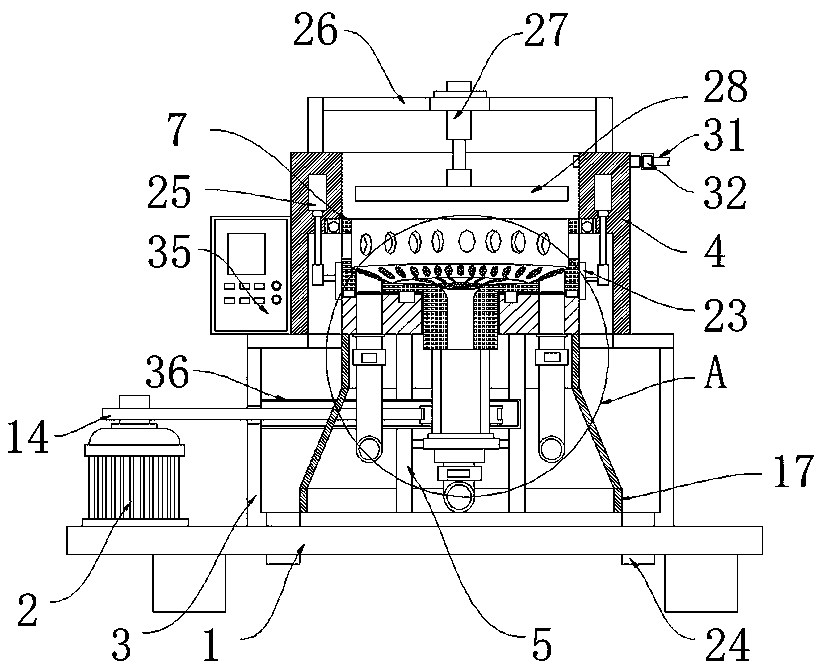

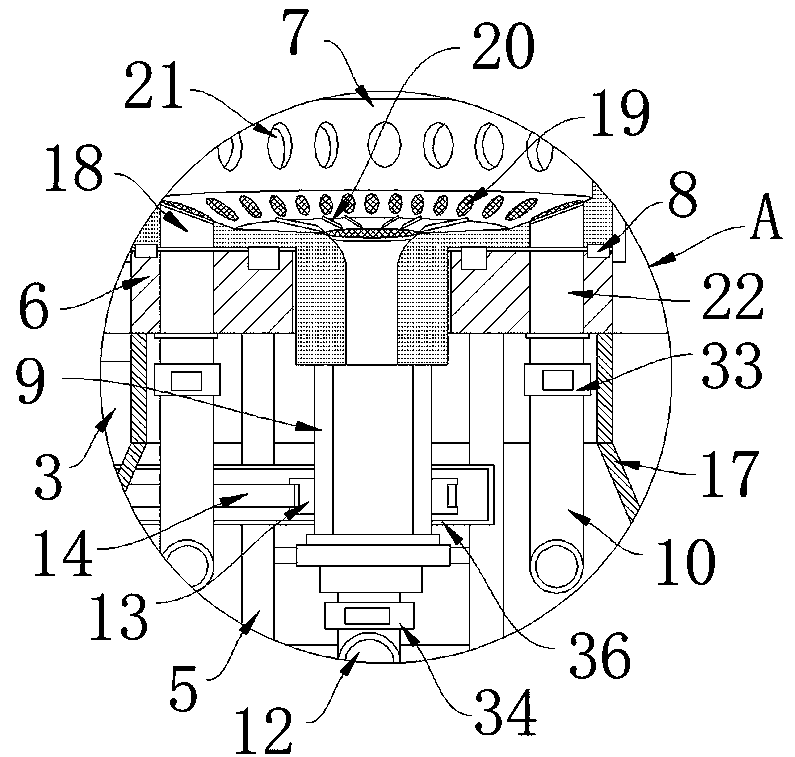

[0028] A sorting device for kitchen waste, comprising a base 1, a body and a drive motor 2 arranged on the upper surface thereof, the body is composed of a sorting bottom box 3 and a sorting top box 4, the sorting top box 4 is located on the upper part of the sorting bottom box 3, And the two are internally connected; the inner bottom wall of the classification bottom box 3 is fixedly connected with a support column 5, and the top of the support column 5 is fixedly connected with a classification bottom ring block 6, and the upper surface of the classification bottom ring block 6 is provided with a T-shaped classification groove block 7, and a waterproof two-way thrust ball bearing 8 for reducing friction is arranged between the two, and the bottom end of the T-shaped classification groove block 7 passes through the inner ring of the classification bottom ring block 6 and is fixedly connected with the first classification pipe 9, The central portion of the inner bottom wall of ...

Embodiment 2

[0034] Different from Embodiment 1, the lower surface of the classification bottom ring block 6 is provided with a second classification pipe 10, the inner surface of the classification bottom box 3 is fixedly connected with a protective box 36 for protecting the synchronous belt 14, and the lower surface of the classification bottom ring block 6 A protective cover 17 connecting the inner bottom wall of the classification bottom box 3 is provided.

[0035] The T-shaped classification tank block 7 is a funnel-shaped structure, an inclined surface is formed between the inner bottom wall and the side wall, and a plurality of second feeding ports 18 are provided on the inclined surface, and a second filter screen 19 is arranged inside the second feeding port 18 , the inner bottom wall of the T-shaped sorting tank block 7 is provided with ribs 20, and the surface of the T-shaped sorting tank block 7 is equidistantly provided with some third feeding ports 21, and the second feeding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com