Intelligent three-dimensional warehouse capable of realizing automatic storage

A three-dimensional warehouse and intelligent technology, applied in the field of automatic storage of intelligent warehouses, can solve the problems of unreasonable stacking of goods, inability to enter and exit at will, and waste of time, so as to improve space utilization, reduce human and financial resources, and smooth the transmission process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

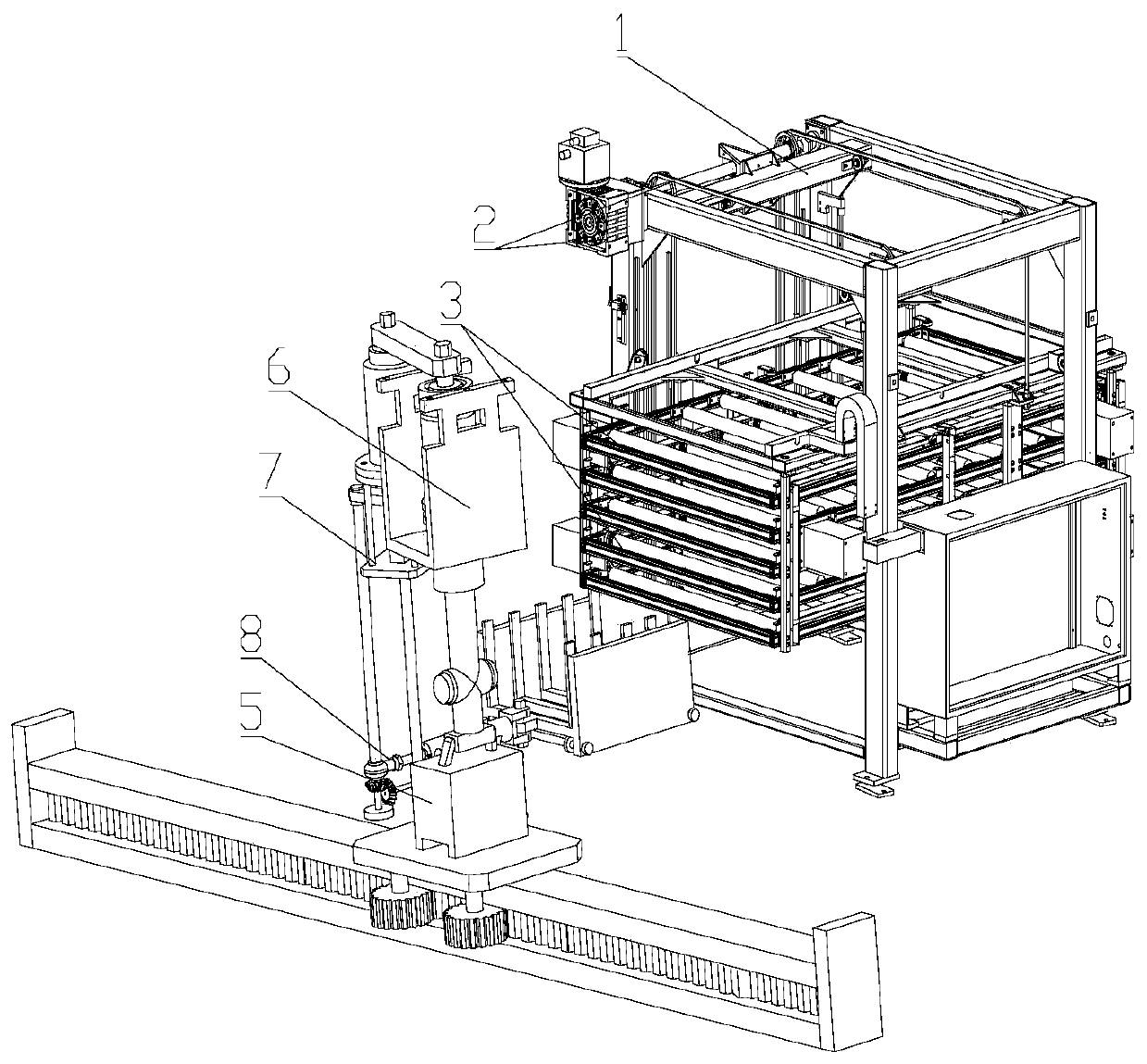

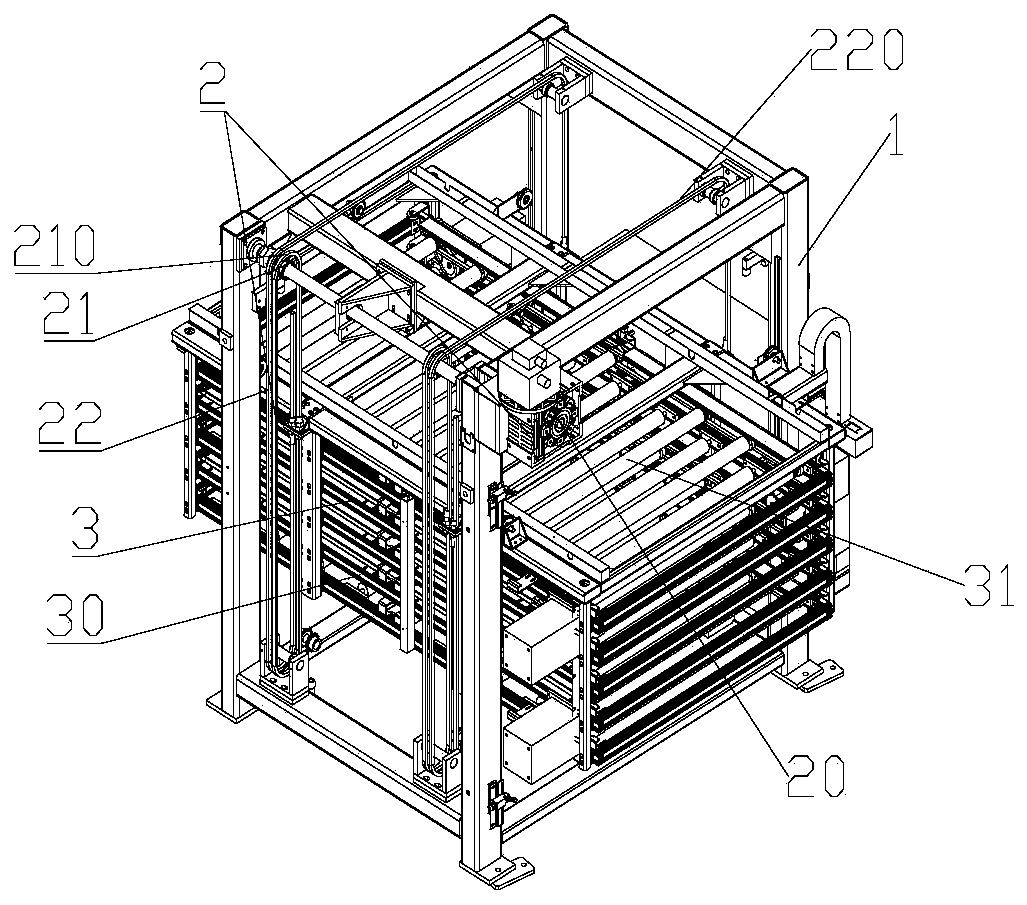

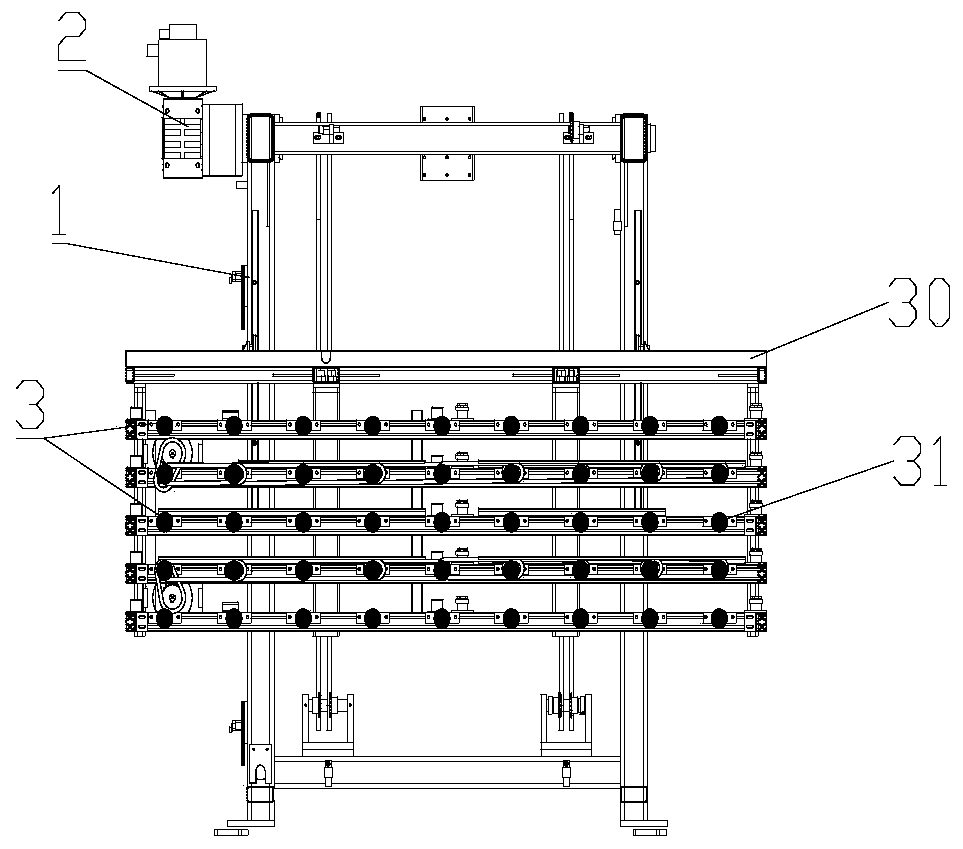

[0038] see Figure 1 to Figure 8 The technical solution provided by the present invention is an intelligent three-dimensional warehouse for automatic storage, including a three-dimensional warehouse frame 1, and a lifting drive structure 2 arranged on the three-dimensional warehouse frame 1, wherein several layers of automatic warehouses are arranged on the three-dimensional warehouse frame 1. The lifting material conveying assembly 3 is equipped with a power mechanism on each layer of the automatic lifting material conveying assembly 3, and a stacking mechanism 4 for conveying materials to several layers of automatic lifting material conveying assemblies 3 is also provided at one end of the three-dimensional warehouse frame 1.

[0039] Specifically, several layers of automatic lifting material conveying components 3 are fixed by connecting plates, and guide rollers that move up and down along the guide rails on the three-dimensional frame 1 are arranged on the connecting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com