Main machine mounting frame

A technology of mounting frame and main engine, which is applied in transportation and packaging, elevators in buildings, etc. It can solve the problems of labor-intensive handling, heavy mounting frame weight, and slow installation speed, so as to reduce labor intensity, reduce weight, and improve Effects on alignment accuracy and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

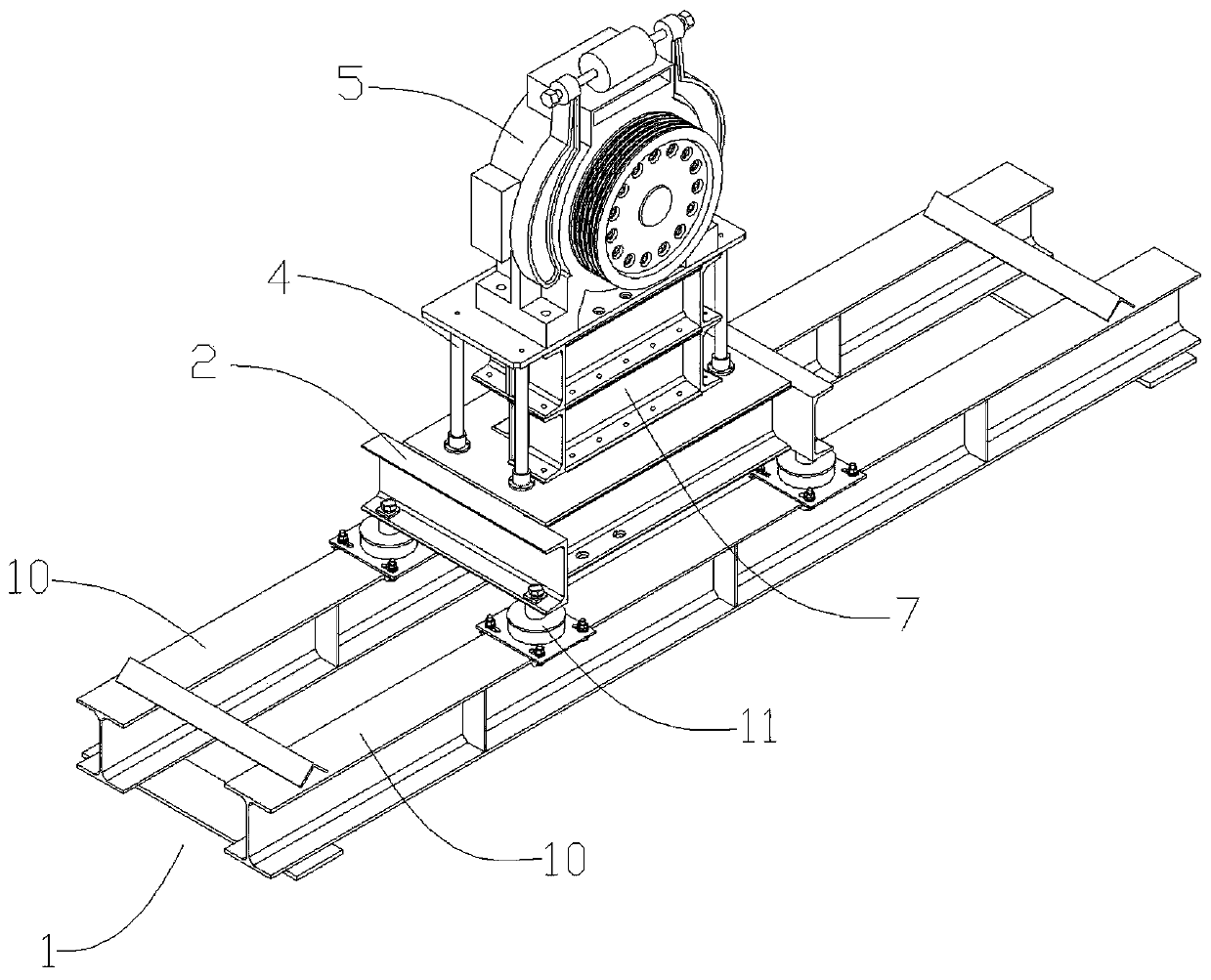

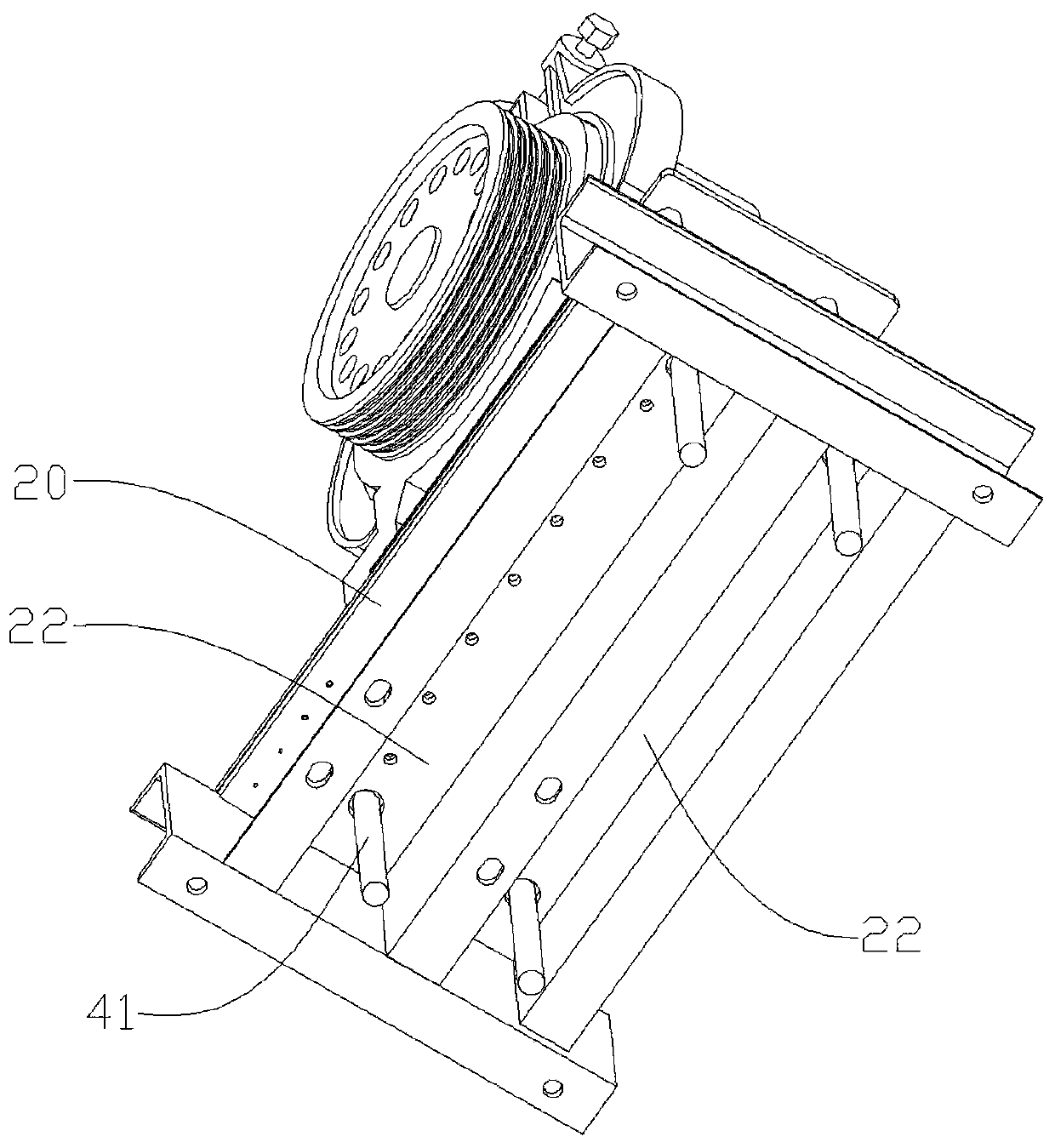

[0036] Such as figure 1 As shown, the host installation frame corresponding to a preferred embodiment of the present invention includes a base 2 installed on the host beam 1, a height adjustment module 7 connected to the base 2, and a height adjustment module 7 connected to The guide assembly 4, the host 5 is installed on the guide assembly 4.

[0037] The main beam 1 includes two I-beams 10 fixedly connected to the wall of the machine room, the base 2 straddles the two I-beams 10, and a shock absorber 11 is connected between the base 2 and the I-beams 10 to Improve the running stability of host 5.

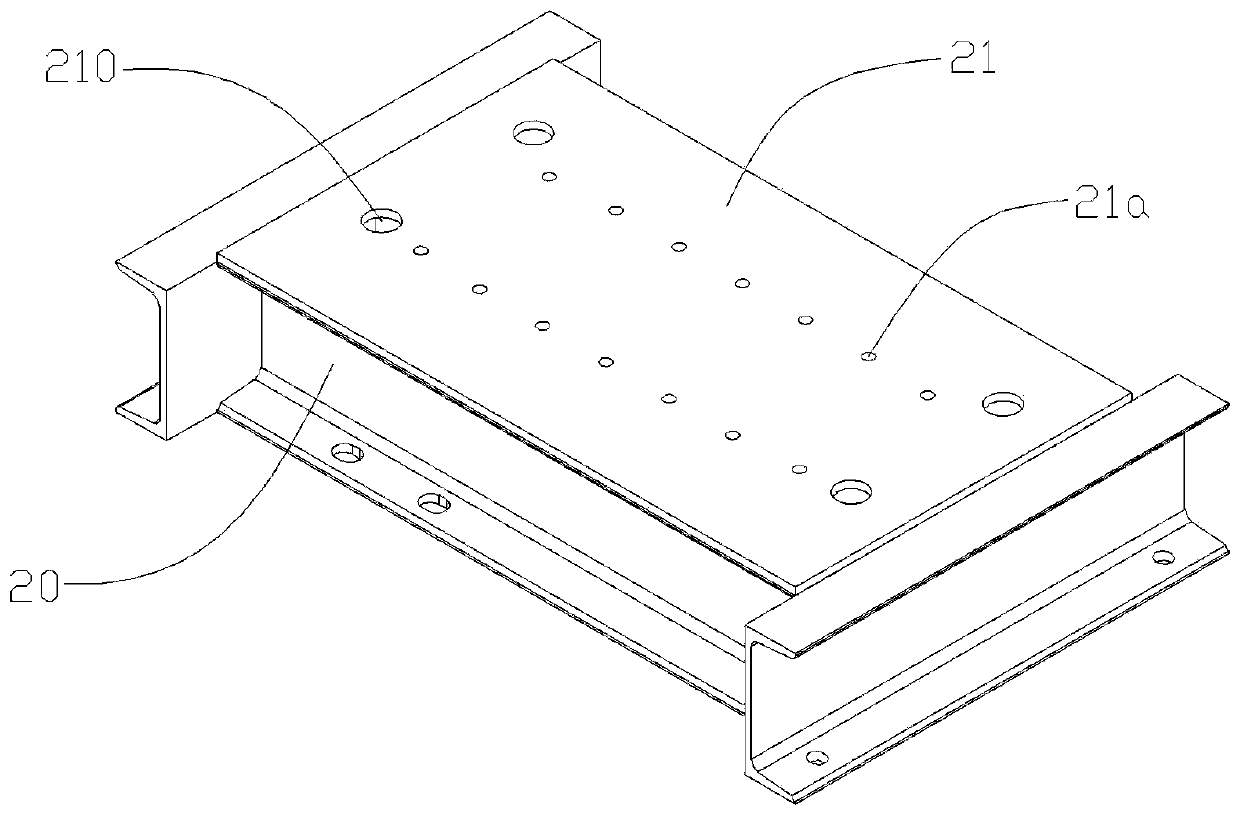

[0038] Such as figure 2 As shown, the base 2 includes a frame body 20 and a mounting plate 21 connected to the frame body 20. The frame body 20 is connected to the I-beam 10 of the main girder 1. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com