Mounting and fixing device of nuclear power station water discharging port flashboard guide groove auxiliary anode

An auxiliary anode and fixing device technology, applied in water conservancy projects, marine engineering, coastline protection and other directions, can solve the problems of difficult installation of auxiliary anodes, insufficient strength, corrosion of steel pipes, etc., so as to reduce the risk and cost of manual maintenance and increase the protection effectiveness. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

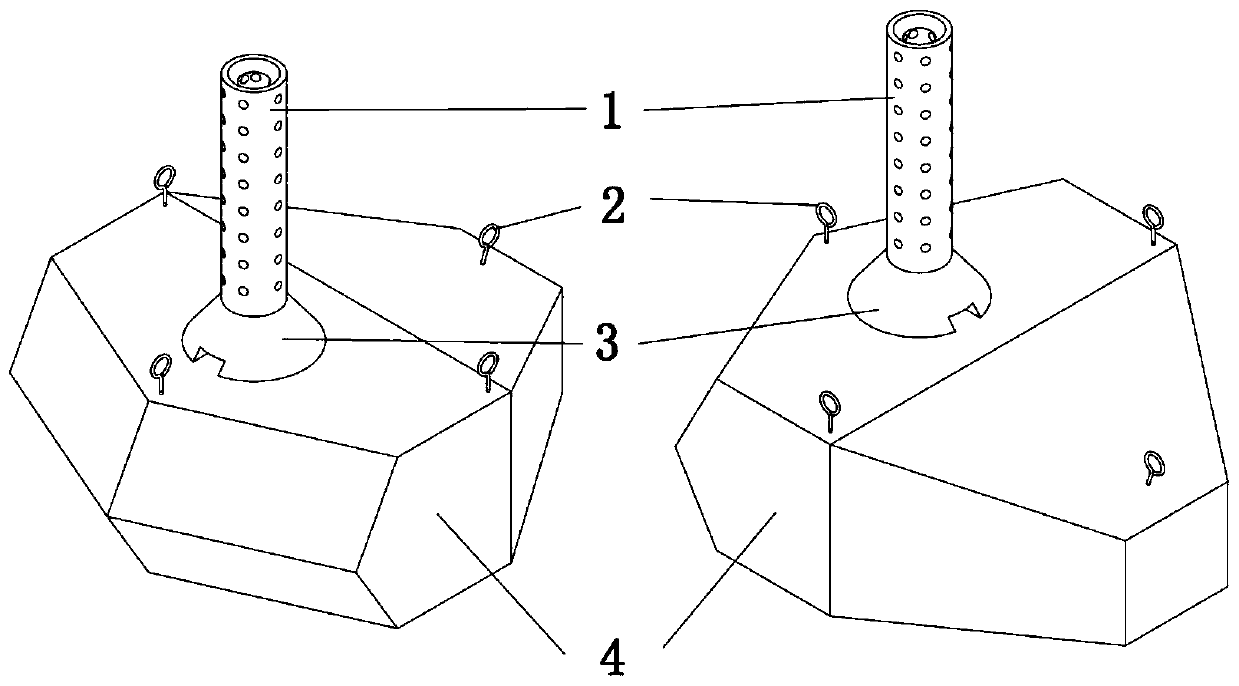

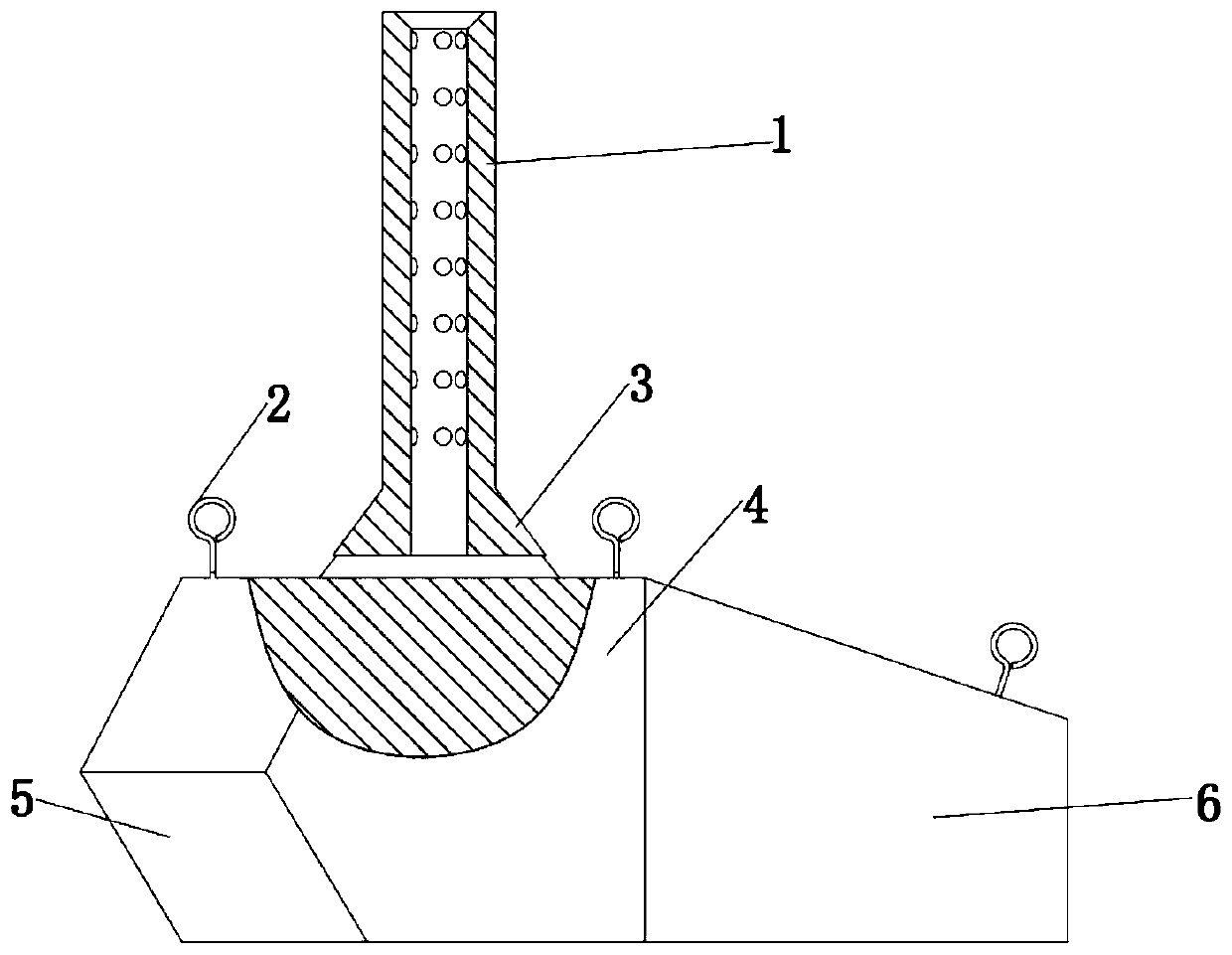

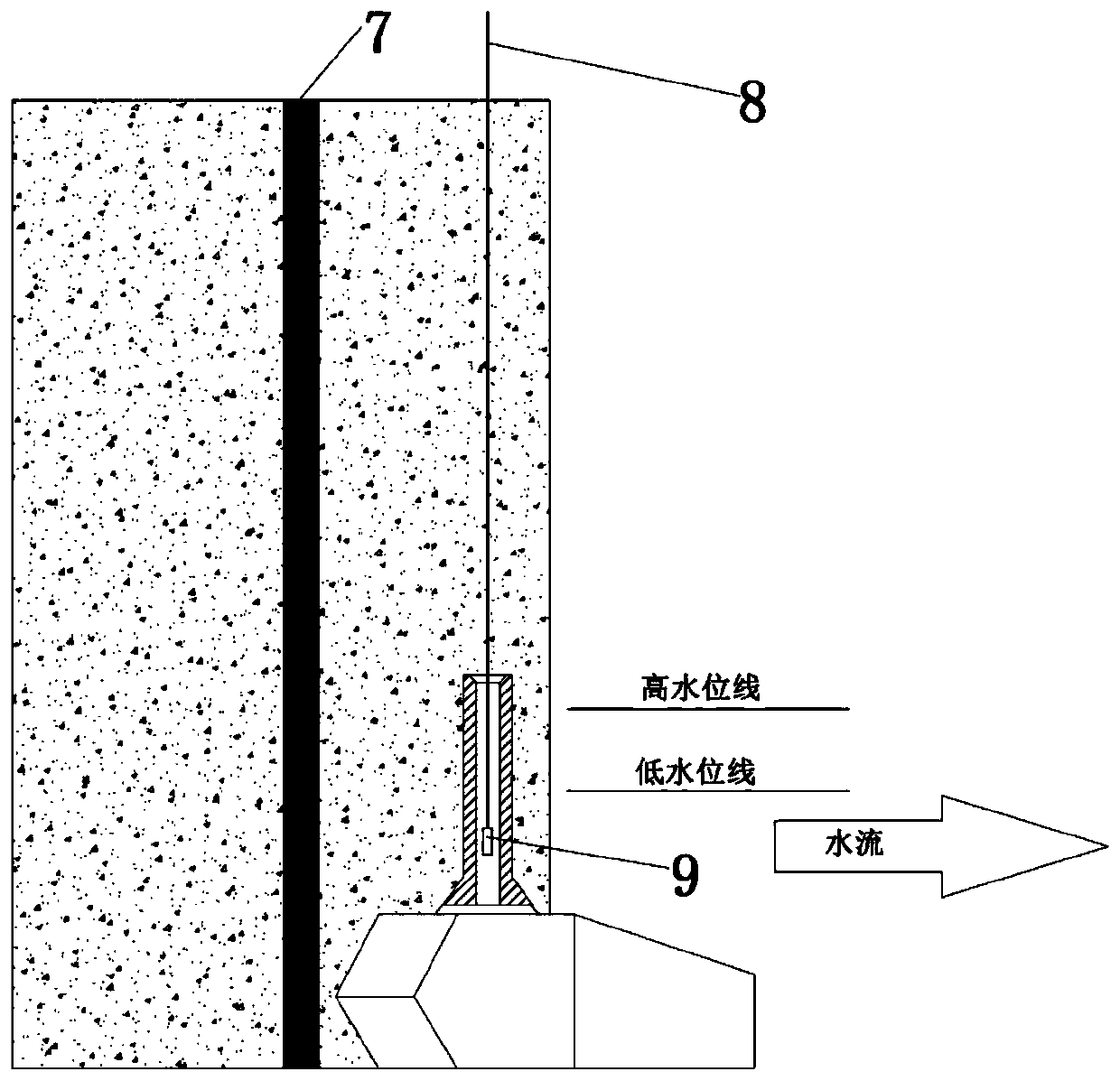

[0021] figure 1 It is a perspective view of an installation and fixing device for an auxiliary anode of a gate plate guide groove of a nuclear power plant drain according to an exemplary embodiment. figure 2 It is a cross-sectional view of an installation and fixing device for an auxiliary anode in a gate plate guide groove of a nuclear power plant according to an exemplary embodiment. image 3 It is an installation schematic diagram of an installation and fixing device for an auxiliary anode of a gate plate guide groove of a nuclear power plant outlet according to an exemplary embodiment. like Figure 1 to Figure 3 As shown, the installation and fixing device for the auxiliary anode of the gate guide groove of the sea water outlet of the nuclear power plant may include: a placement cylinder 1 and a base 4; the side wall of the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com