Mechanical oil production well full-bore scale-preventing plugging tubular column tool

A full-bore, production well technology, applied in earthwork drilling, sealing/isolation, wellbore/well components, etc., can solve problems such as blocked liquid inlet channels, no liquid production volume, and large scale scaling. Achieve the effect of easy release, long-term effect, and convenient and free choice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

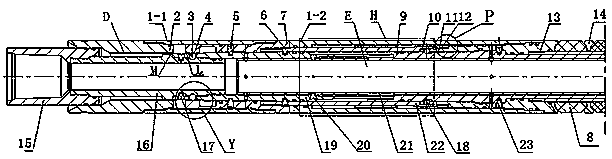

[0019] See Figure 1-2 , 4-5, 8, the structure of the upper assembly of the full-diameter anti-scaling plugging string tool for mechanical production wells:

[0020] The upper joint 15 is threadedly connected with the throwing hand 16, and is respectively inserted into the fishing joint 2 and the upper central pipe 19 and fixed on the upper central pipe 19 with scissors 17, which is used to prevent the automatic throwing of the hand when the tool is not fully released . The steel ball 3 is put into the hole of the upper central tube 19 and inserted into the annular groove of the hand 16, the piston A4 is sleeved on the upper central tube 19 and fixed on the hand 16 with the shear nail 5, forming a steel ball lock mechanism to prevent Lost hand 16 and the tool in advance when the tool is going downhole, causing an accident; the principle of this lock is that the upper center pipe 19 will move down due to the gravity of the tool and the lower pipe string when going downhole, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com