Axial plunger pump of railway track switching system

A technology for axial piston pumps and railway tracks, which is applied in the direction of pumps, multi-cylinder pumps, liquid displacement machinery, etc., can solve the problems of hydraulic system stop working, falling off, etc., and achieve the effect of improving weak links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

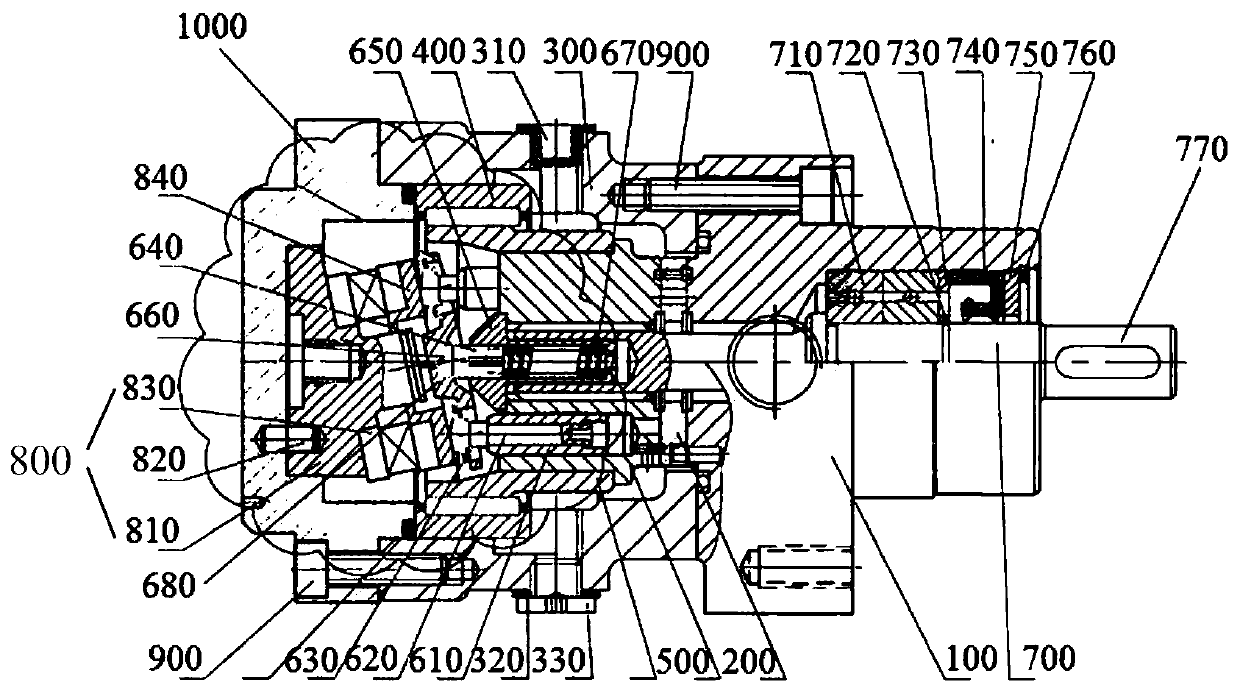

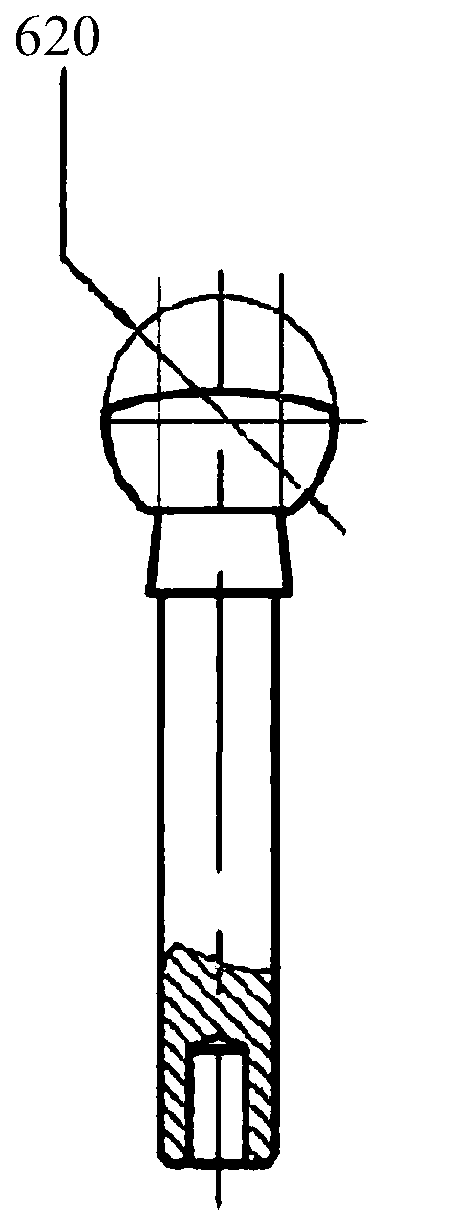

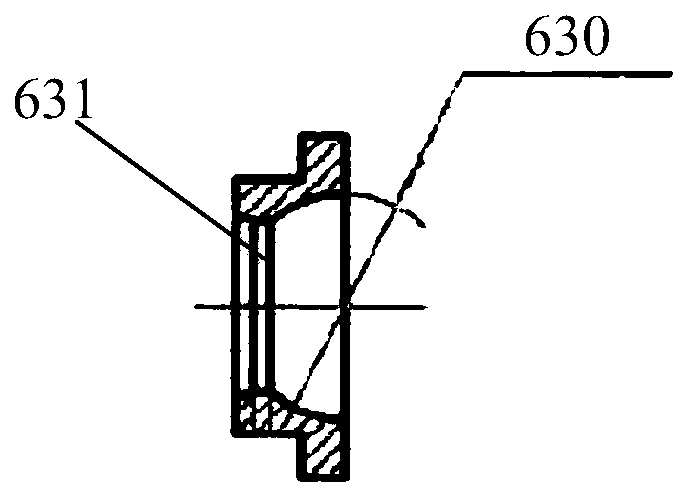

[0027] figure 1 ~ is a structural representation of the present invention. figure 2 It is a structural schematic diagram of the plunger assembly of the present invention. image 3 It is a structural schematic diagram of the sliding shoe of the present invention. Figure 4 It is the connection diagram of the plunger assembly and the sliding shoe of the present invention.

[0028] Such as Figure 1~4 As shown, an axial plunger pump for a railway track switch system includes: a pump body 100, an oil distribution plate 200, a pump casing 300, a needle bearing 400, a cylinder body 500, a plunger assembly 600, a transmission shaft 700, The swash plate structure 800, the screw 900 and the end cover 1000, the pump body 100 is connected with the pump casing 300 through the screw 900, the oil distribution plate 200 is set between the pump body 100 and the pump casing 300, the cylinder body 500 is connected with the pump casing through the needle bearing 400 300 internal support con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com