Shock absorber and elastic vibration damping device

A vibration damping device and technology of shock absorbers, which are applied to shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of insufficient stiffness, large space occupied by shock absorbers, and no vibration reduction effect, etc. The effect of improving bearing capacity and fatigue resistance, simple and beautiful appearance, and enhancing practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

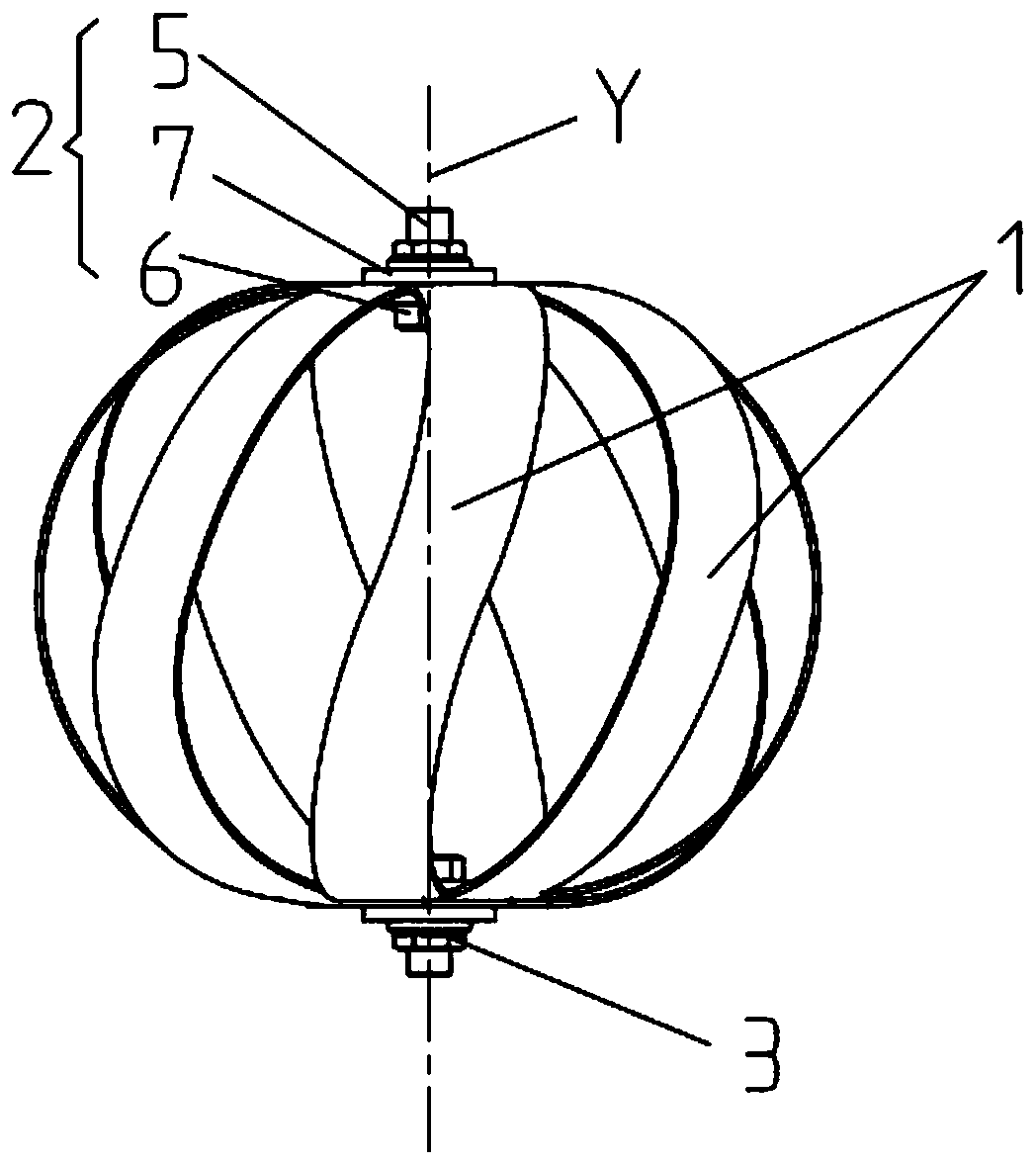

[0038] Such as Figure 1a-1b As shown, the shock absorber in this embodiment includes: several elastic elements 1, upper fasteners 2 and lower fasteners 3, and the upper fasteners 2 and lower fasteners 3 are arranged coaxially, In this embodiment, the upper fastener 2 and the lower fastener 3 both include: bolts 5, nuts 6 and washers 7; the first connection position of each elastic element 1 is connected to the upper fastener 2. The second connection position of each annular elastic element 1 is connected to the lower fastener 3, so that several elastic elements 1 are centered on the common axis Y of the upper fastener 2 and the lower fastener 3, The circumferential direction is arranged as a sphere or an ellipsoid;

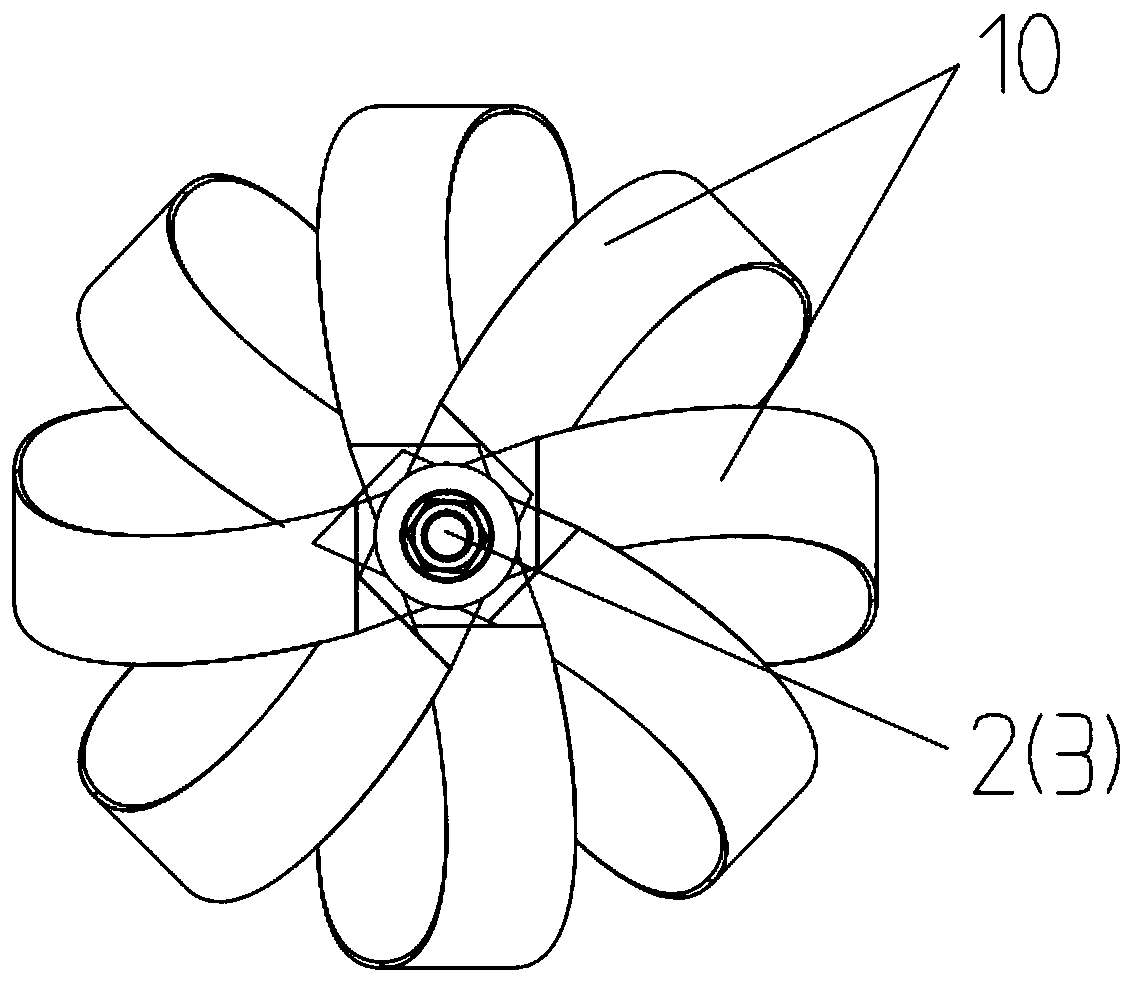

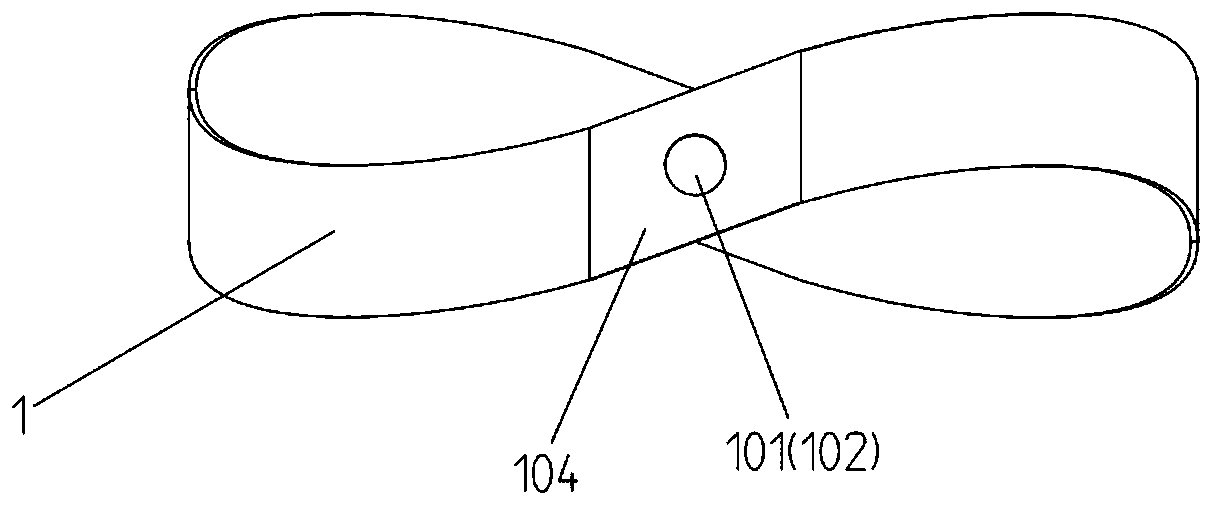

[0039] In this example, if Figure 2a-2b As shown, at least one of the elastic elements 1 is a "∞"-shaped Mobius ring structure, which is connected to the other end after twisting one end of the strip-shaped shrapnel unit 10 by 180° (such as butt joint or lap j...

Embodiment 2

[0044] This embodiment provides an elastic damping assembly, such as Figure 4 As shown, it includes: a vibration damping assembly; a first connecting plate 100 connected to one end of the vibration damping assembly; and / or a second connecting plate 200 connected to one end of the vibration damping assembly.

[0045] Specifically, the damping assembly includes a first damping unit 300 and / or a second damping unit 300', wherein the first damping unit is the damper described in Embodiment 1, and the The first connecting plate 100 is connected to the upper fastener 2 , and / or the second connecting plate 200 is connected to the lower fastener 3 .

[0046] The second damping unit 300' is similar in structure to the first damping unit 300, as Figures 5a-5b As shown, the second damping unit 300' includes: several damping pieces 1', first fasteners 2' and second fasteners 3', and the first fasteners 2' and the second fasteners The two fasteners 3' are coaxially arranged; the first ...

Embodiment 3

[0050] The only difference between this embodiment and Embodiments 1 and 2 is that Figure 10-11 As shown, the strip-shaped elastic piece unit 10 / vibration damping sheet 1' includes: a first elastic piece unit 401 and / or a second elastic piece unit 402, preferably, the first elastic piece unit 401 and the second elastic piece unit 402 are arranged at intervals , to form a sandwich structure, and the first elastic piece 401 and the second elastic piece 402 are correspondingly provided with pin holes 403, and connecting parts such as pins pass through the pin holes 403 on the first elastic piece 401 and the second elastic piece 402 in order to connect all The first elastic piece 401 and the second elastic piece 402; at the same time, one or both of the first elastic piece 401 and the second elastic piece 402 are made of metal or rubber or a combination of metal and rubber , such as by covering the surface of the metal with a rubber layer or made of other elastic-plastic material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com