Ultrasonic guided wave multi-resolution focusing imaging pipeline detection method and device

An ultrasonic guided wave and pipeline inspection technology, which is used in measuring devices, solids analysis using sonic/ultrasonic/infrasonic waves, and material analysis using sonic/ultrasonic/infrasonic waves, etc. Low resolution, difficult to overcome the contradiction between the ultrasonic guided wave detection resolution and the moving distance of the focus point, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with drawings and embodiments.

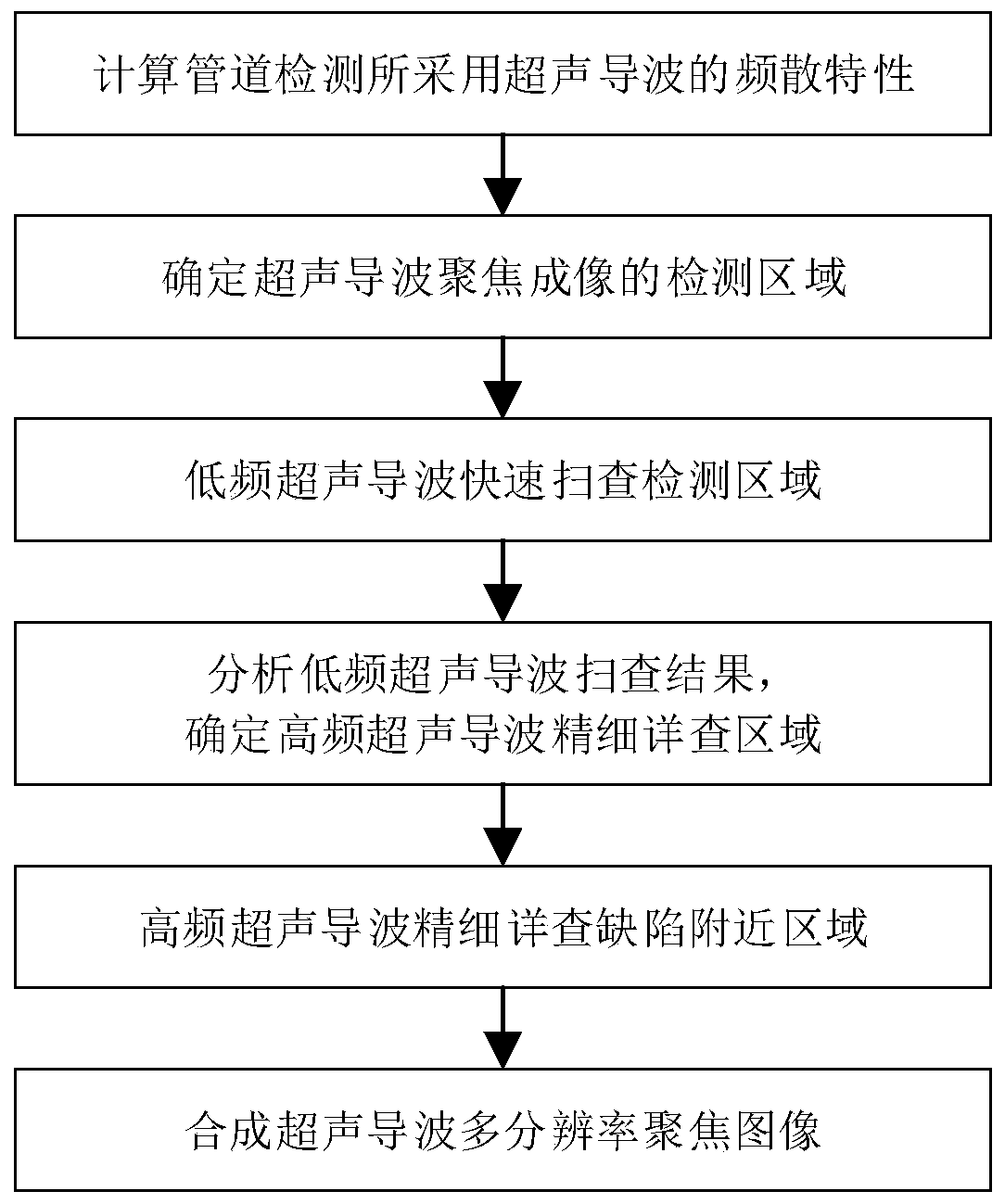

[0036] as attached figure 1 As shown, an ultrasonic guided wave pipeline detection method capable of realizing multi-resolution focused imaging provided by the present invention, the steps are as follows:

[0037] (1) Calculate the dispersion characteristics of ultrasonic guided waves used in pipeline inspection

[0038] According to the geometric dimensions such as the inner and outer diameters of the pipe and the material mechanical parameters such as Young's modulus and Poisson's ratio, the dispersion characteristics of the SH0 mode ultrasonic guided wave are solved by a commercial ultrasonic guided wave dispersion characteristic calculation program.

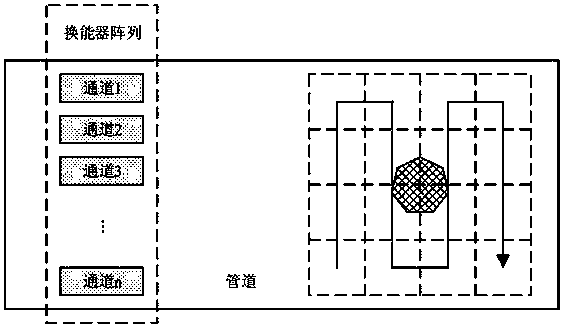

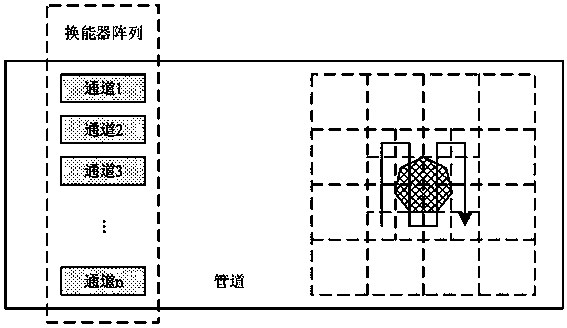

[0039] (2) Determine the detection area of ultrasonic guided wave focusing imaging

[0040] According to the working conditions of the pipeline, the inspectors predict the pipeline area that may have defects, and d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap