Stator armature polarity detection device

A polarity detection and armature technology, which is used in measuring devices, motor generator testing, measuring electricity, etc., can solve the problems of complex operation, high cost, low efficiency, etc., and achieve simple detection process, intuitive results, and complex compensation procedures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

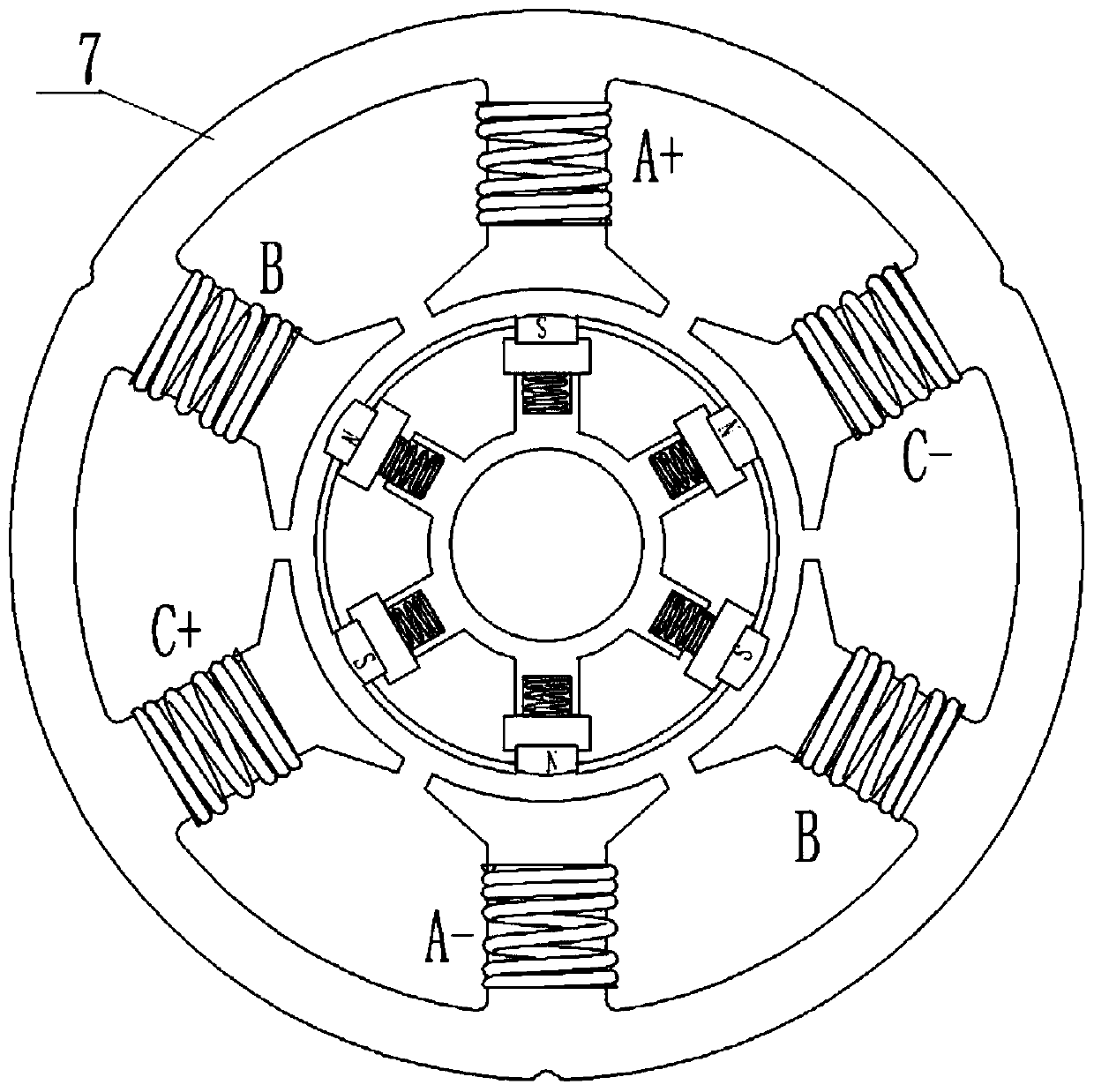

[0029] The present invention will be further described below in conjunction with the drawings and specific embodiments.

[0030] The invention designs a motor stator polarity detection device. The device itself has a simple structure, and when the stator polarity is detected by using it, the operation is convenient. For a multi-slot stator, the stator polarity sequence can be evaluated at one time with high efficiency and accuracy.

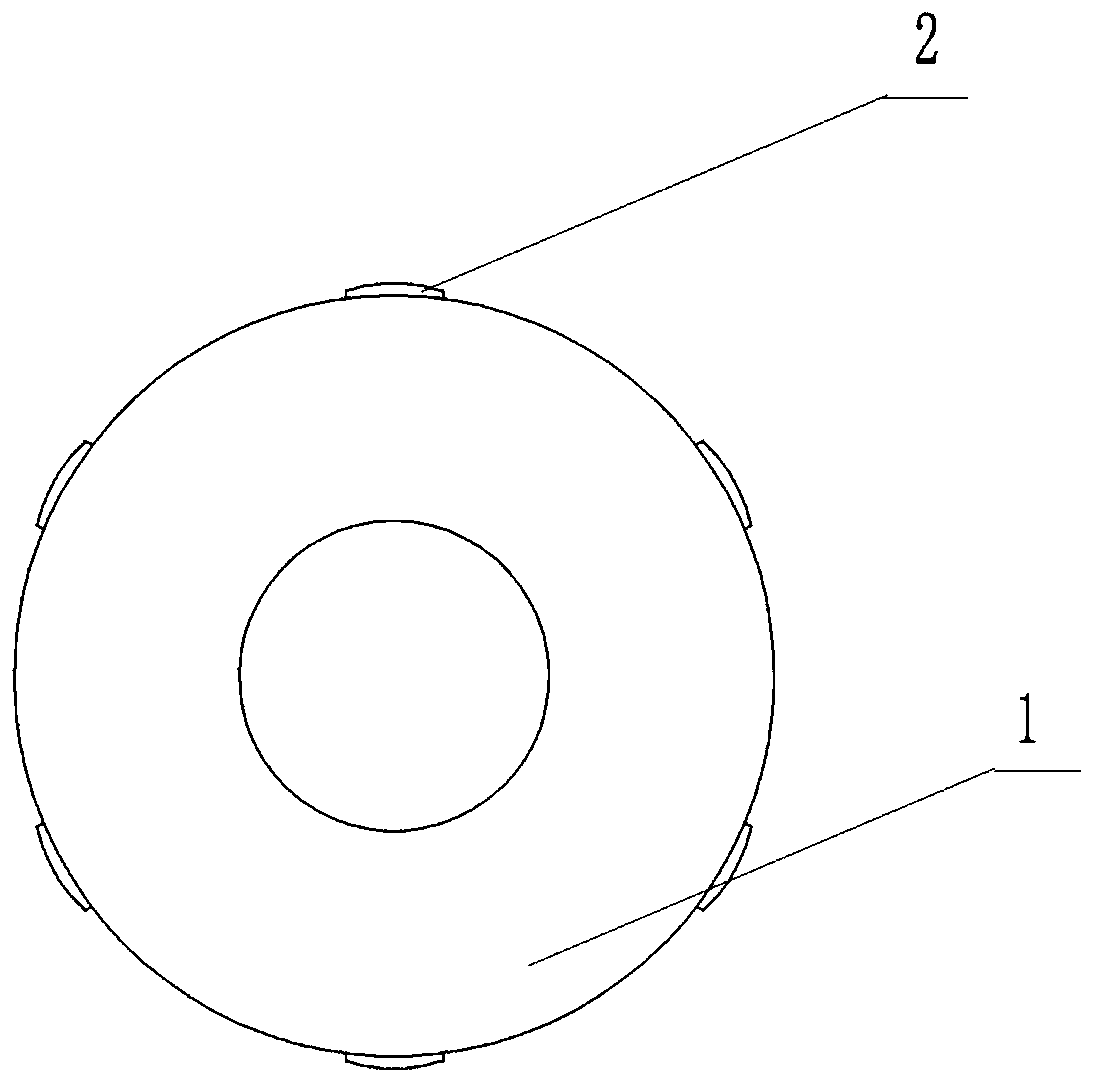

[0031] The packaged shape of the motor stator polarity detection device in this embodiment is as follows: figure 1 As shown, it includes a housing 1 and a detection component 2 located inside the housing 1, wherein figure 1 It can be seen that the housing 1 of this embodiment is a ring-shaped closed housing, and a part of the detection device 2 is exposed along the outer circumference of the housing.

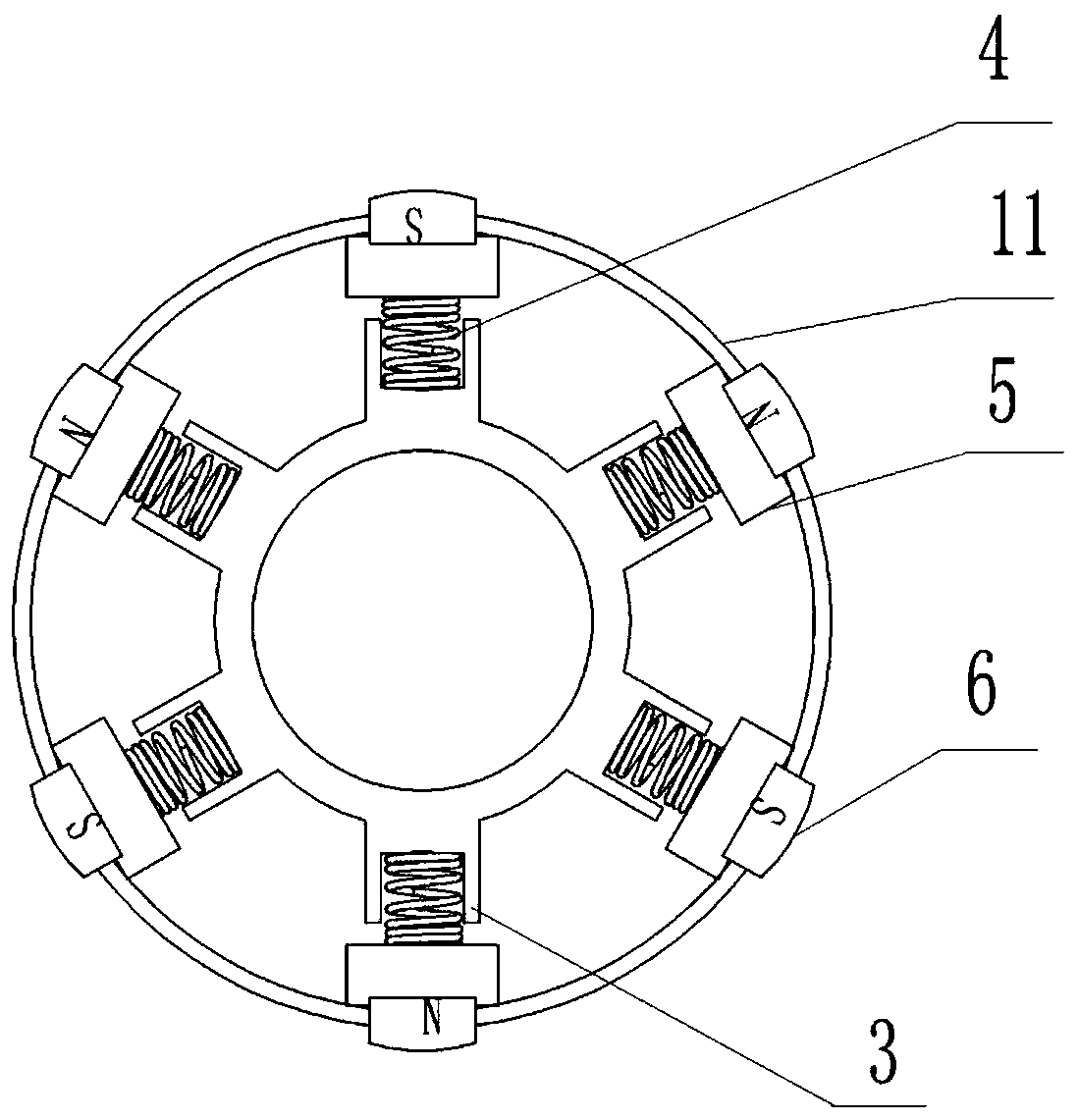

[0032] From figure 2 It can be seen that the detection component 2 of this embodiment includes a positioning seat 3, an elastic component 4, a magnetic po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com