A color difference gloss detection device compatible with multiple products and its operating method

A detection device, gloss technology, applied in the direction of measurement device, color/spectral characteristic measurement, material analysis by optical means, etc., can solve the problem of small precision parts with small size, easy distraction of staff, and different sizes of materials. and other problems, to achieve the effect of increasing utilization efficiency, reducing detection and reset time, and compact layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

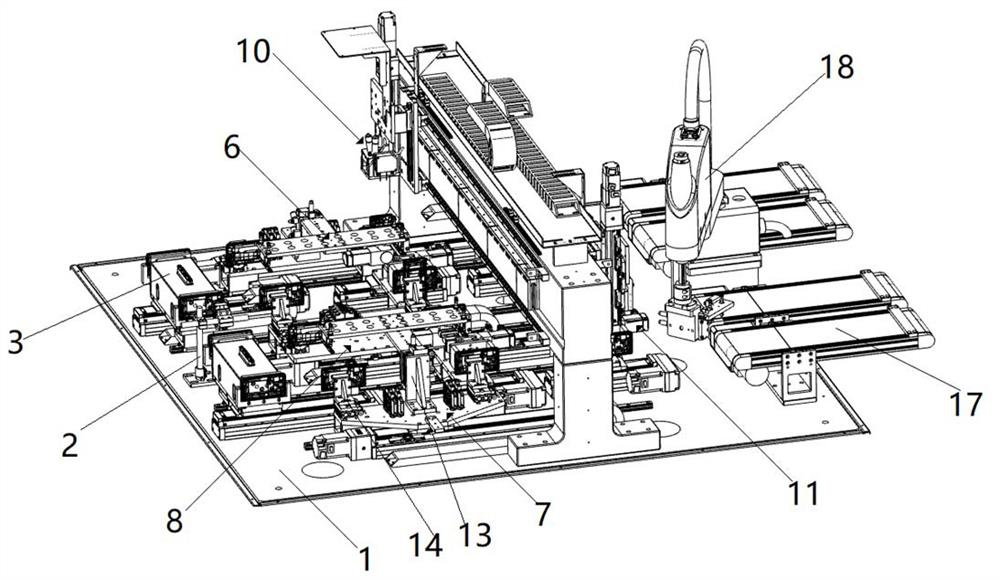

[0053] Please refer to Figure 1-5 A color difference gloss detecting device compatible with a variety of products, characterized in that the work platform 1, which is horizontal, provided on the work platform 1,

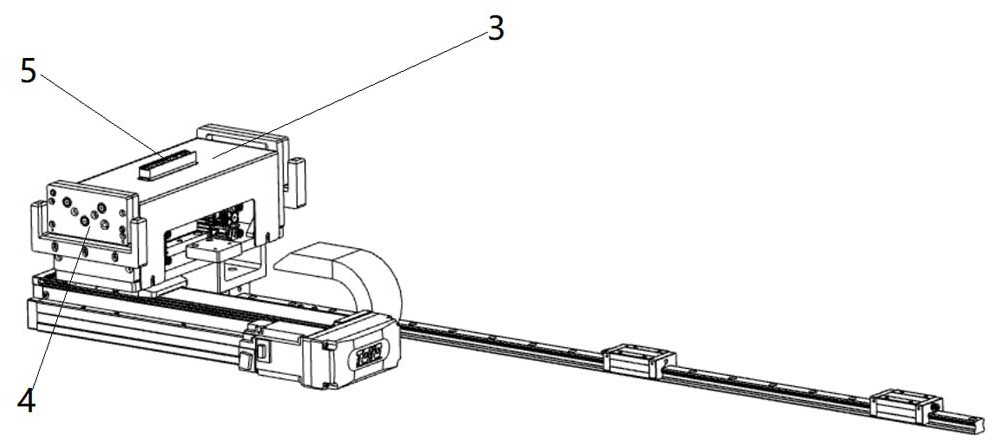

[0054] The upper body includes a scanning code device 2 and two sheet devices; the upper device comprises a sheet rail, a carrier 3, and a sheet driving device; the carrier 3 is respectively attached to the top. Stop 4 and the top adsorption station 5, the side adsorption station 4 is used for the upper body of the side, and the top suction station 5 is used for the upper workpiece.

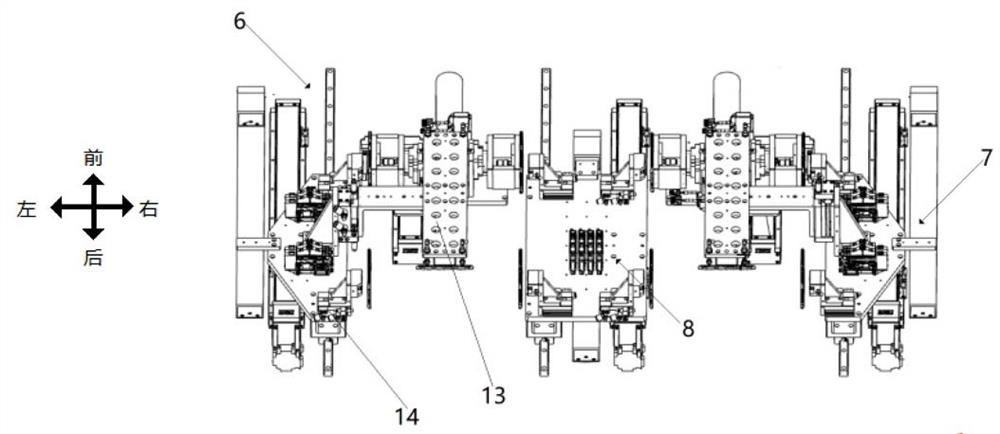

[0055] The detection channel includes a transfer mechanism and a detection mechanism above the transfer mechanism; the transfer mechanism includes the same and relatively disposed first transfer device 6 and the second transfer device 7, and is located first. The third moving device 8 between the transfer device 6 and the second transfer device 7 corresponds to the first transfer device 6 a...

Embodiment 2

[0063] A color difference gloss detection device compatible with a variety of products, wherein the transfer mechanism is sequentially disposed in the transmission direction, a color difference detection bit, a gloss detection bit, a lower material position;

[0064] It includes the following method of operation,

[0065] S100, scanning code device scans the top / side workpiece, performs information reading and binding; the binding top / side workpiece is then sent to the upper device;

[0066] S200, the upper body is acting on the transfer bit to the transfer mechanism; the transfer mechanism drives the top / side workpiece to move the top / side workpiece to the color difference detection position and the gloss detection bit, and the color difference detecting device and the gloss detecting device are detected. And upload the detection data to the control system, the control system sizes the detected top / side workpiece according to the level screening information in the datab...

Embodiment 3

[0069] This embodiment mainly introduces the specific method of operation of S200, and the steps are as follows:

[0070] S211, two upper devices at the same time the workpiece 1, the workpiece 2, the workpiece 3, the workpiece 4, the workpiece 5, and the workpiece 6 from left to the first transfer device, the second transfer device, and The front side of the third transfer device;

[0071] S212, the transfer mechanism drives the workpiece 1, the workpiece 2, the workpiece 3, the workpiece 4, the workpiece 5, and the workpiece 6 moves to the color difference detection bits to perform color difference detection, the chromatic aberration monitoring device is sequentially detected from left to right; at the same time The workpiece 7, the workpiece 8, the workpiece 9, the workpiece 10, the workpiece 11, and the workpiece 12 are on the rear side of the first transfer device, the second transfer device, and the third transfer device;

[0072] S213, the transfer mechanism drives the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com