Structure-reinforced photovoltaic panel fixing frame and mounting method

A photovoltaic panel and reinforced technology, applied in the field of power equipment, can solve the problems of reduced power generation efficiency, prone to breakage, photovoltaic panels can not reach the optimal sunlight angle, etc., and achieves easy angle adjustment, small amount of engineering, and power generation efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

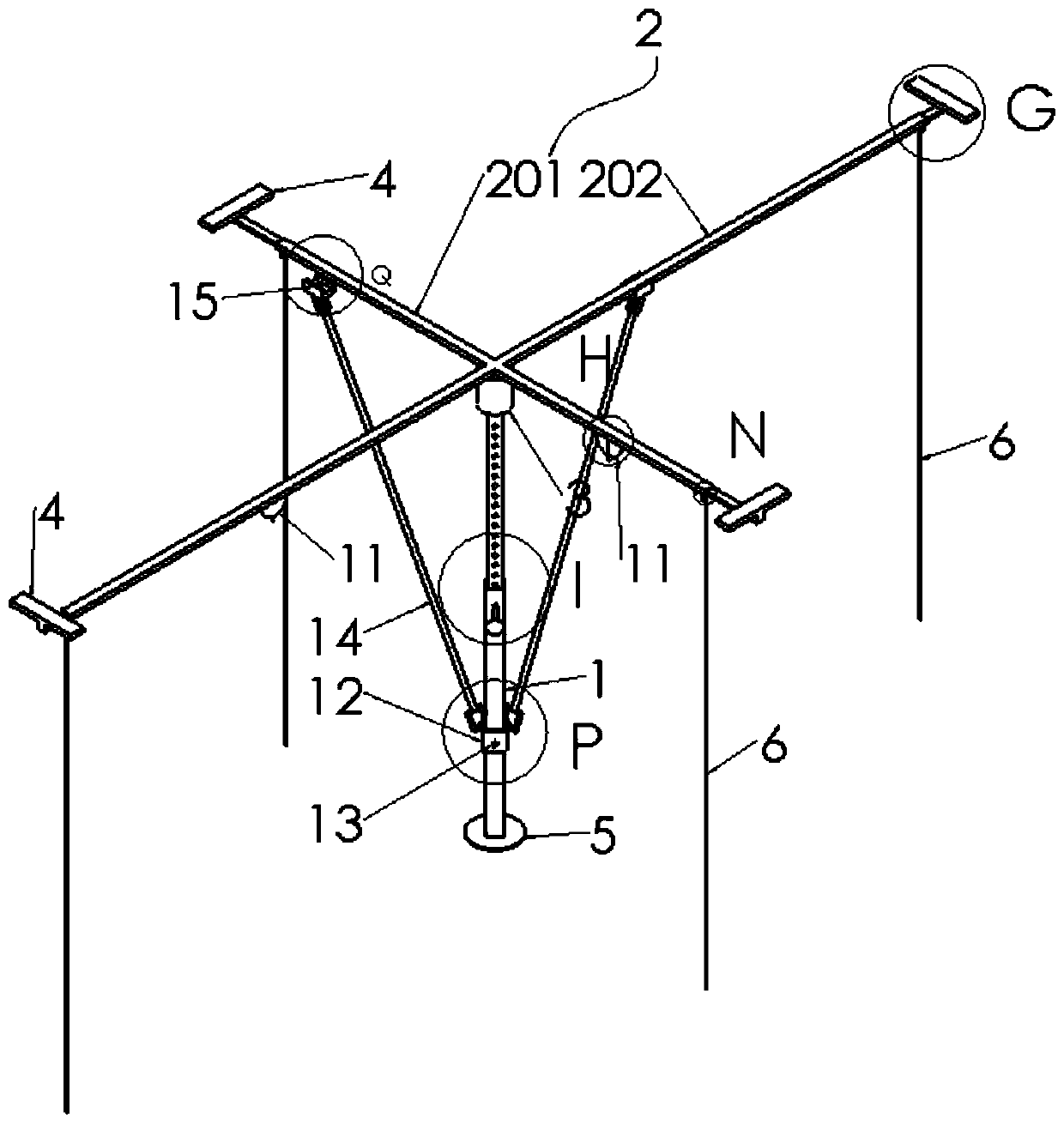

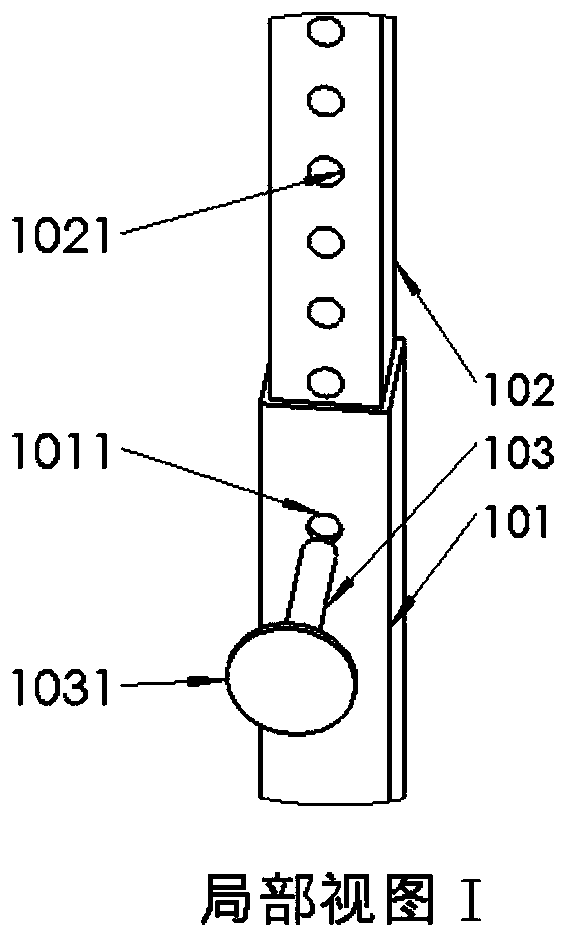

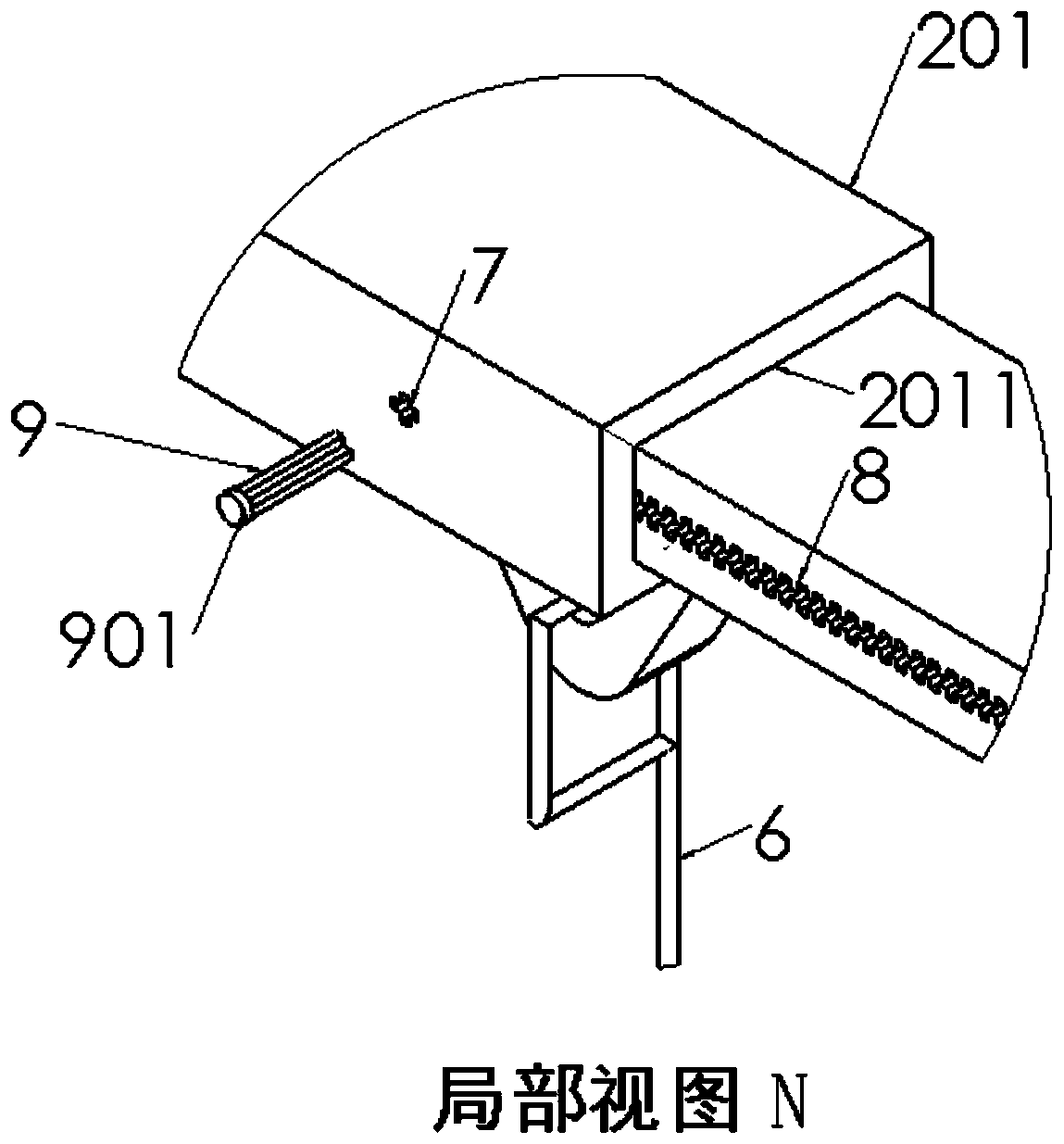

[0055] Implementation Example 1: Reference Figure 1 to Figure 13, a structurally reinforced photovoltaic panel fixing frame, comprising: a main support rod 1, the lower end of the main support rod 1 is fixedly connected to a flange 5; a mounting frame 2, and the middle part of the lower surface of the mounting frame 2 is fixedly connected to a universal joint 3 , the mounting frame 2 is connected to the upper end of the main support rod 1 through the universal joint 3, and a stay rope 6 is connected to each mounting frame 2 located at four directions of the universal joint 3, front, rear, left, and right, and the mounting frame 2 is ferromagnetic. Material: sliding sleeve 12, the sliding sleeve 12 is slidably connected on the main support rod 1, the side wall of the sliding sleeve 12 is provided with a screw hole passing through the inner and outer walls, and the screw hole is threadedly connected with a bolt 13 matching the screw hole, The sliding sleeve 12 fixes the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com