Low-energy direct-current high-voltage type electron accelerator

An electron accelerator and DC high voltage technology, applied in the direction of electrical components, accelerators, etc., can solve the problems of electron accelerators with complex structure, high manufacturing cost, and low work efficiency, and achieve improved beam utilization, convenient maintenance, and power conversion rate Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

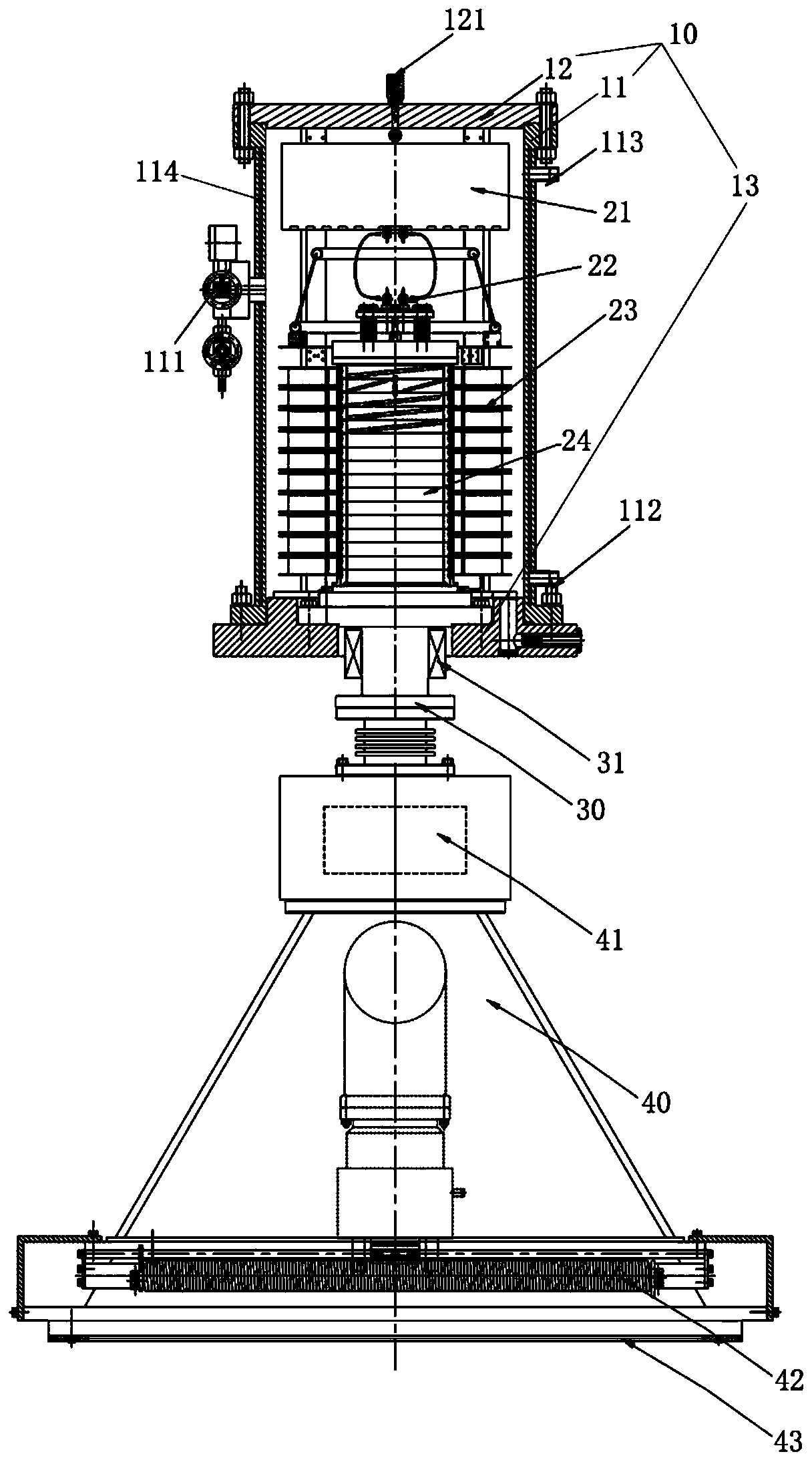

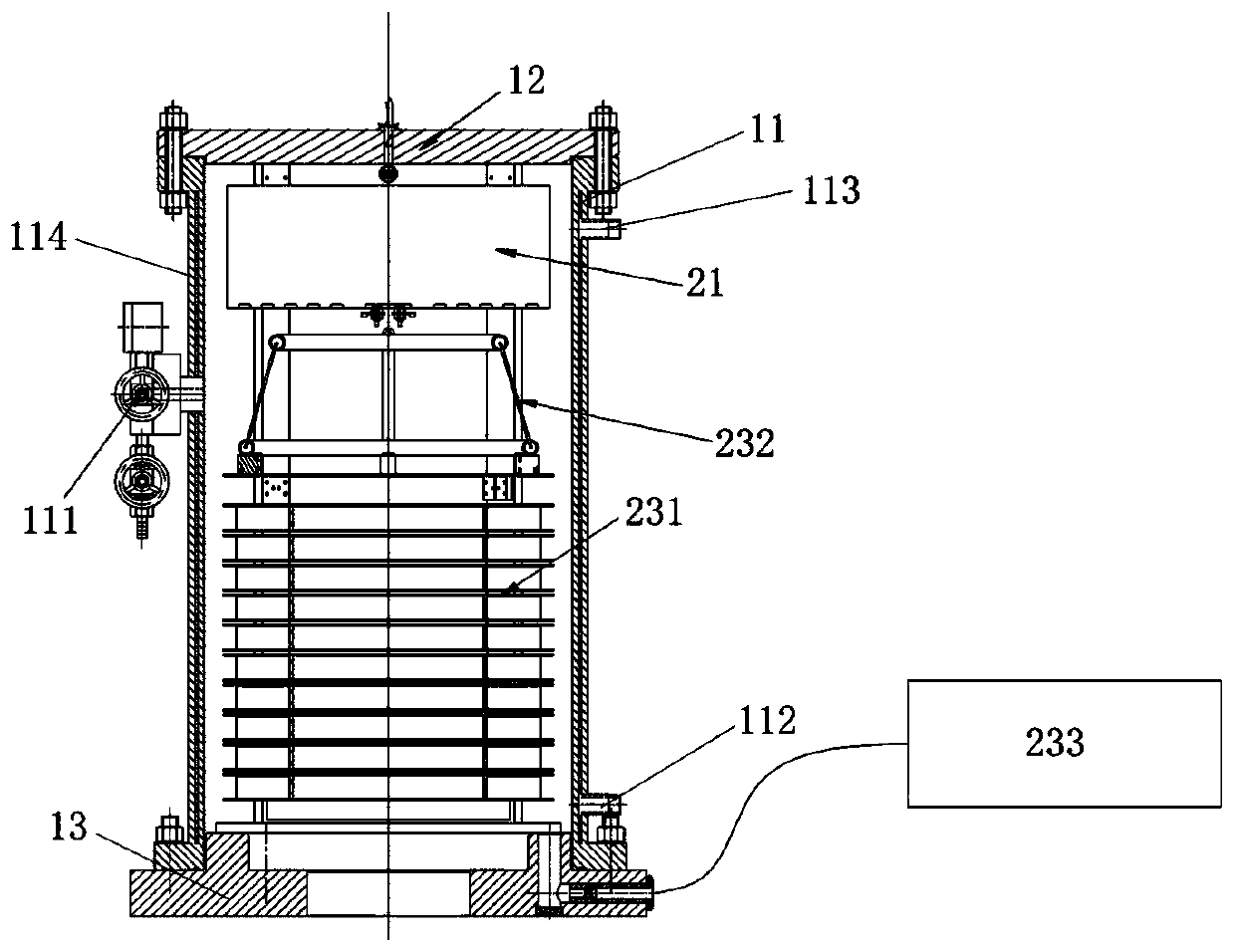

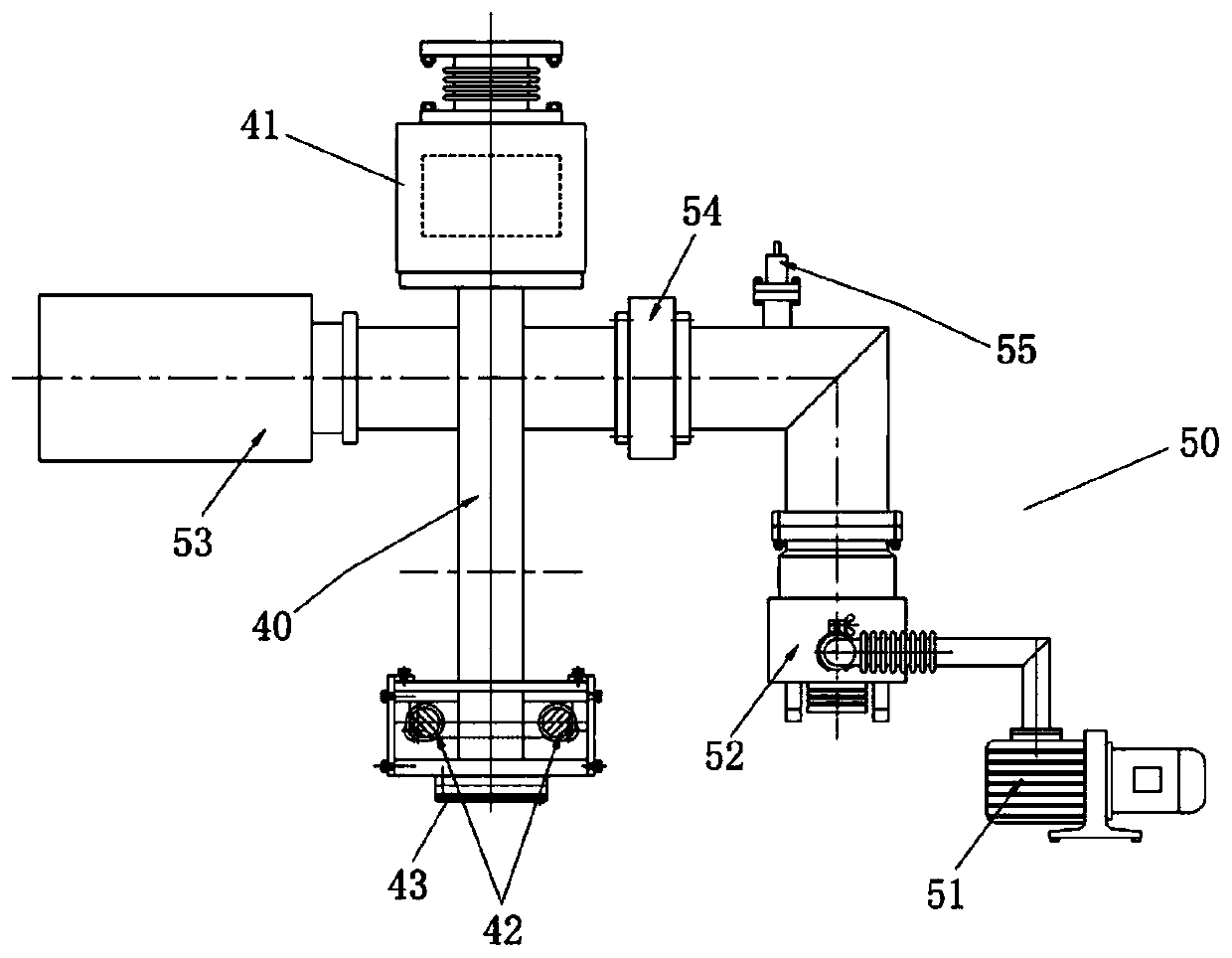

[0019] like figure 1 As shown, a low-energy DC high-voltage electron accelerator of the present invention includes a steel cylinder assembly 10 , a filament power source 21 , an electron gun 22 , a high-voltage assembly 23 , an acceleration tube assembly 24 , a vacuum tube 30 and a scan box 40 . The steel cylinder assembly 10 is a sealed pressure-resistant container, the filament power supply 21 and the electron gun 22 are installed inside the steel cylinder assembly 10, the high-voltage assembly 23 is installed in combination with the steel cylinder assembly 10, and the acceleration The tube assembly 24 passes through the bottom flange of the steel tube assembly 10 and is connected to the vacuum tube 30 , and the end of the vacuum tube 30 away from the acceleration tube assembly 24 is connected to the scan box 40 . combine image 3 It can be seen that a vacuum pump assembly 50 is installed on the side of the scanning box 40 to construct a high vacuum environment for electron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com