Compact wall type hydraulic cylinder mechanism for shoemaking sole pressing machine

A hydraulic cylinder, compact technology, used in the direction of shoemaking machinery, footwear, applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

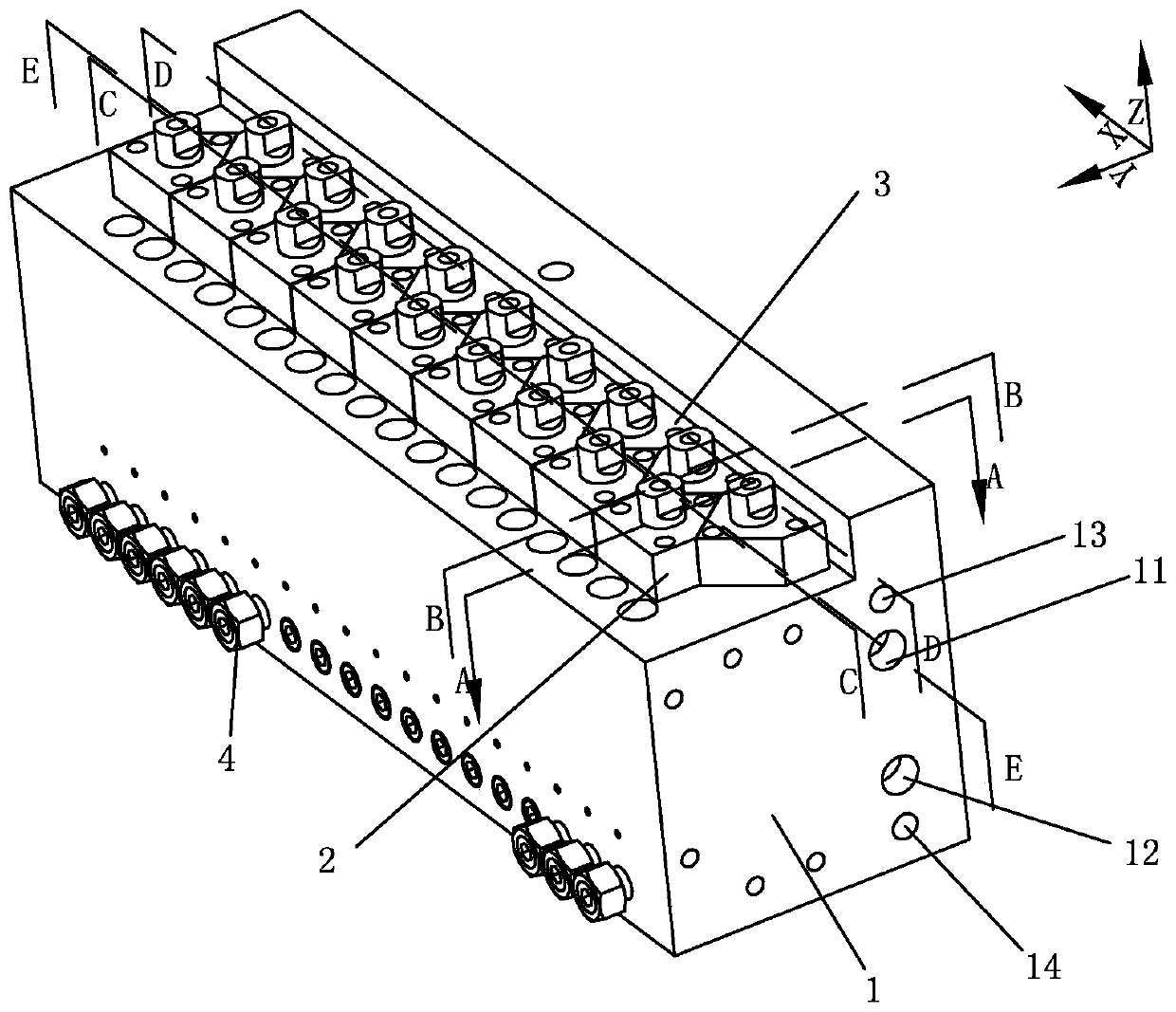

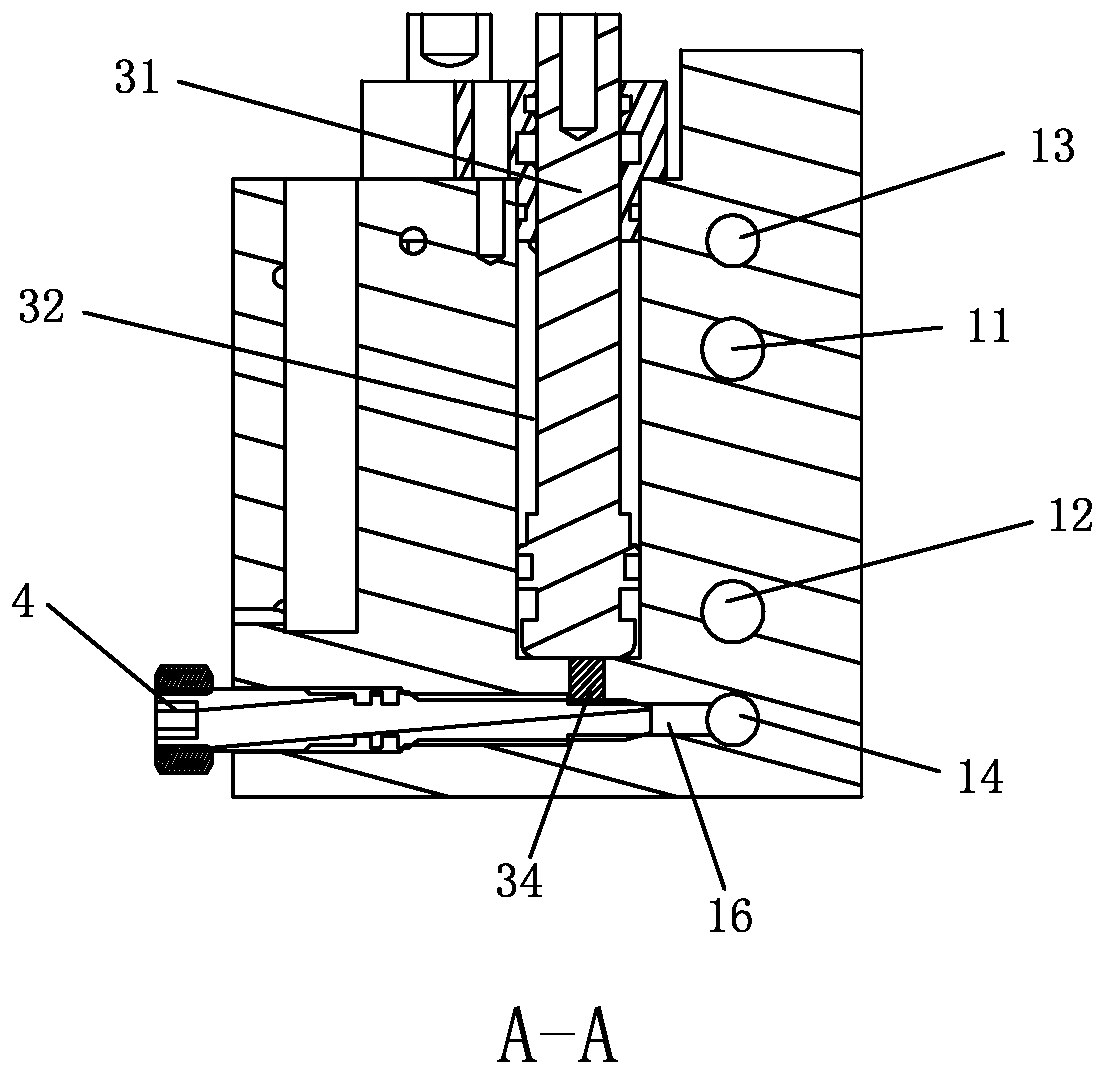

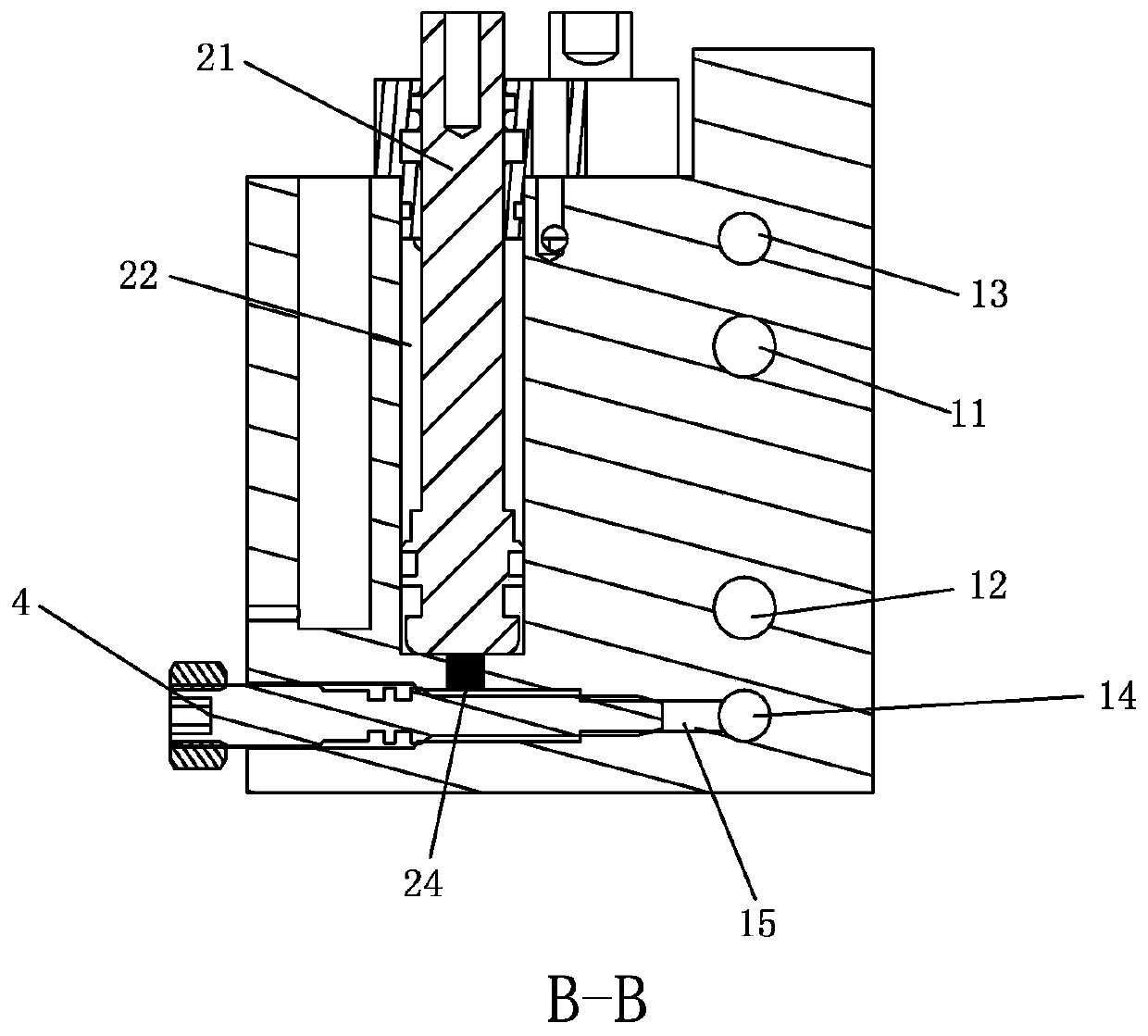

[0032] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples. Coordinates X, Y, and Z in the figure represent the left-right direction, front-back direction, and up-down direction of the case, respectively.

[0033] Such as figure 1 As shown in -7, this case provides a compact wall-mounted hydraulic cylinder mechanism for a shoe-making sole press, which includes a machine table 1, a first press cylinder group 2 and a second press cylinder group 3, and the machine table 1 It includes a first oil passage 11 and a second oil passage 12 . The first cylinder group 2 includes several first piston rods 21 and several first cylinder grooves 22 for the telescopic movement of the first piston rods 21 and arranged along the left and right direction of the machine 1. The first cylinders The groove 22 includes a first oil passage 23 communicating with the first oil passage 11 and a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com