Stuffing grinding mortar for production of sweet dumplings

A mortar and stuffing technology, applied in the field of stuffing grinding mortar, can solve problems such as uneven crushing, loss of cleaning brushes, and reduced grinding efficiency, so as to avoid loss, improve efficiency, and improve food quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

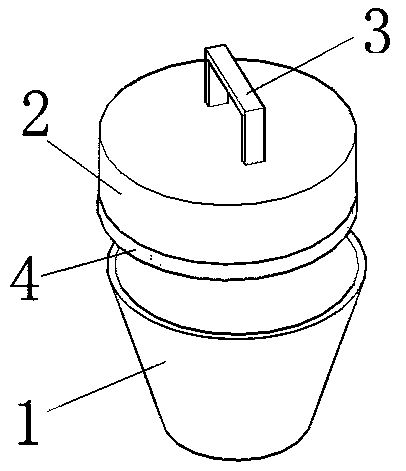

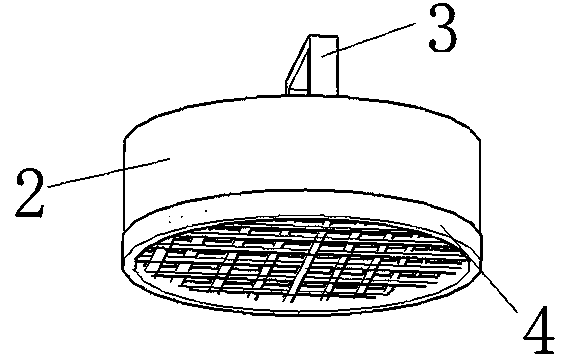

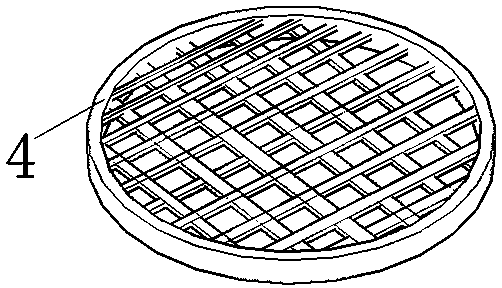

[0025] see Figure 1-4 , a filling mortar for making Lantern Festival, comprising a mortar body 1 and a mortar cover 2 arranged on the mortar body 1, the mortar cover 2 is provided with a handle 3, the A pestle (not shown in the figure) is placed in the main body of the mortar 1, and the pestle is in the shape of a round table, and a screen 4 for screening filling powder is provided between the main body 1 of the mortar and the lid 2 of the mortar , the screen 4 is detachably connected with the mortar main body 1 and the mortar cover 2 through threads, the screen 4 is a 100-mesh screen 4, and the particle size of the screen 4 can be adjusted according to actual needs. replace.

[0026] The mortar of the present invention is provided with a detachably connected screen 4 between the mortar main body 1 and the mortar cover 2. When in use, the filling material is first placed in the mortar main body 1 and squeezed with a pestle. Crush, then install the screen 4 and the mortar co...

Embodiment 2

[0030] see Figure 5 , a filling mortar for making Lantern Festival, comprising a mortar body 1 and a mortar cover 2 arranged on the mortar body 1, the mortar cover 2 is provided with a handle 3, the A pestle (not shown in the figure) is placed in the main body of the mortar 1, and the pestle is in the shape of a round table, and a screen 4 for screening filling powder is provided between the main body 1 of the mortar and the lid 2 of the mortar , the sieve 4 is detachably connected with the mortar body 1 and the mortar cover 2 through threads, the sieve 4 is a 150-mesh sieve 4, and the particle size of the sieve 4 can be adjusted according to actual needs. replace.

[0031] The bottom center of the mortar main body 1 is provided with a bottom protrusion, the surface of the bottom protrusion forms a smooth curve with the bottom of the mortar main body 1, and the included angle of the bottom protrusion ( Figure 4 In a) is 20°C, the height of the bottom protrusion ( Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com