Self-adaptive speed measurement device for steel sheet pile (H-section steel) with counter weight

A self-adaptive measuring and steel sheet pile technology, applied in length measuring devices, metal processing equipment, metal rolling, etc., can solve problems such as large deviation, can not guarantee the matching of billet rolling rhythm and finishing rolling rhythm, and achieve maintenance The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

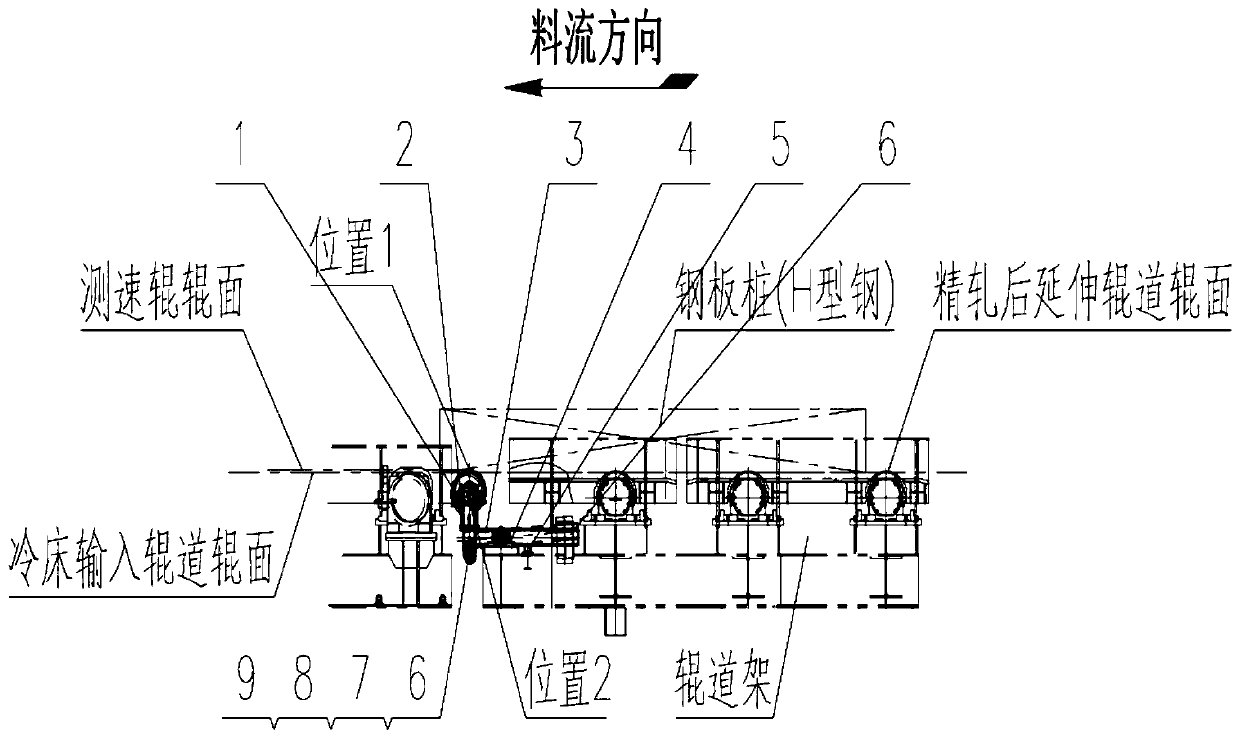

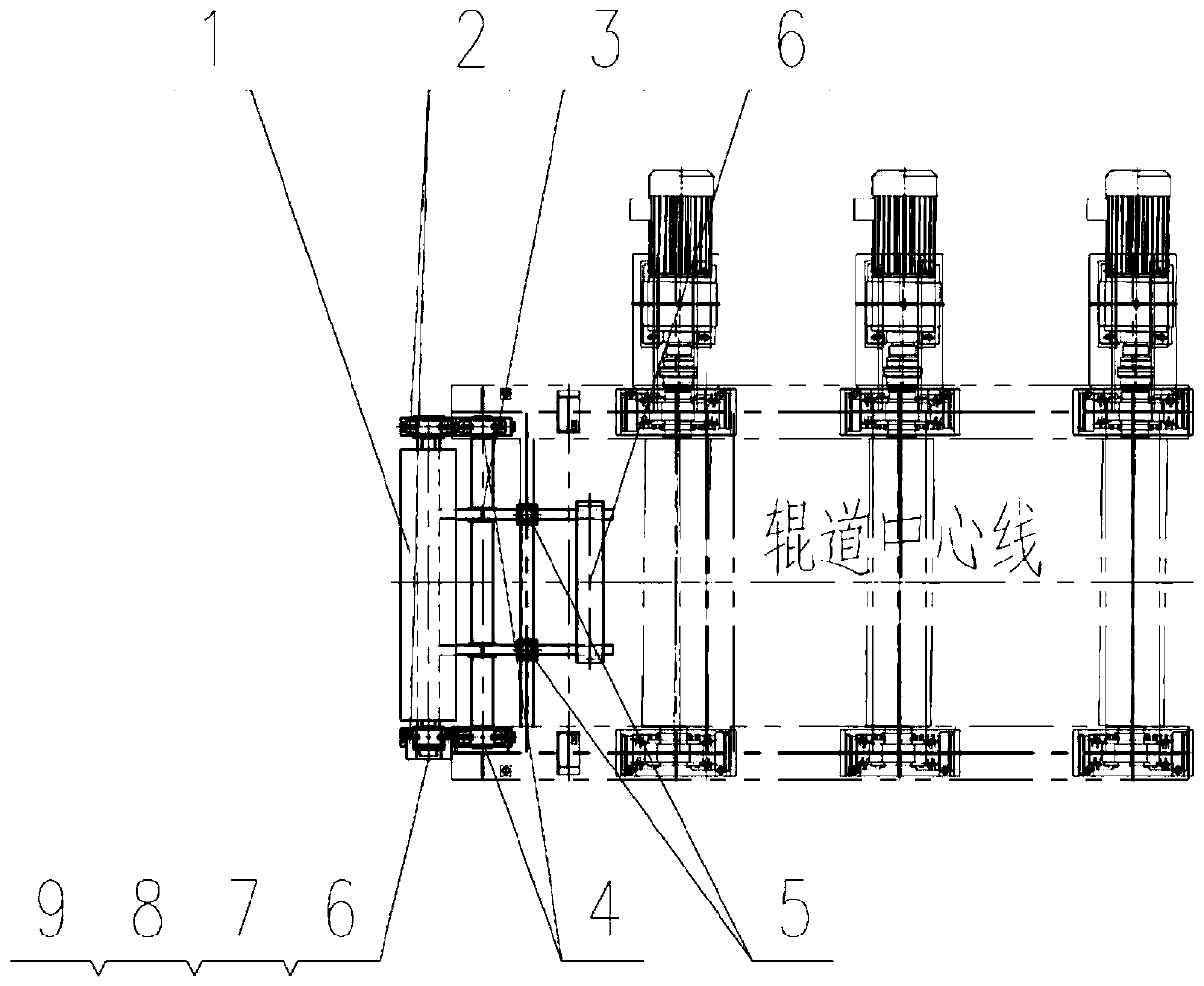

[0019] Such as Figure 1-3 As shown, a steel sheet pile (H-shaped steel) self-adaptive speed measuring device with a counterweight in this embodiment includes a speed measuring roller 1 assembly, an encoder assembly 10, a buffer 5, and a counterweight 6.

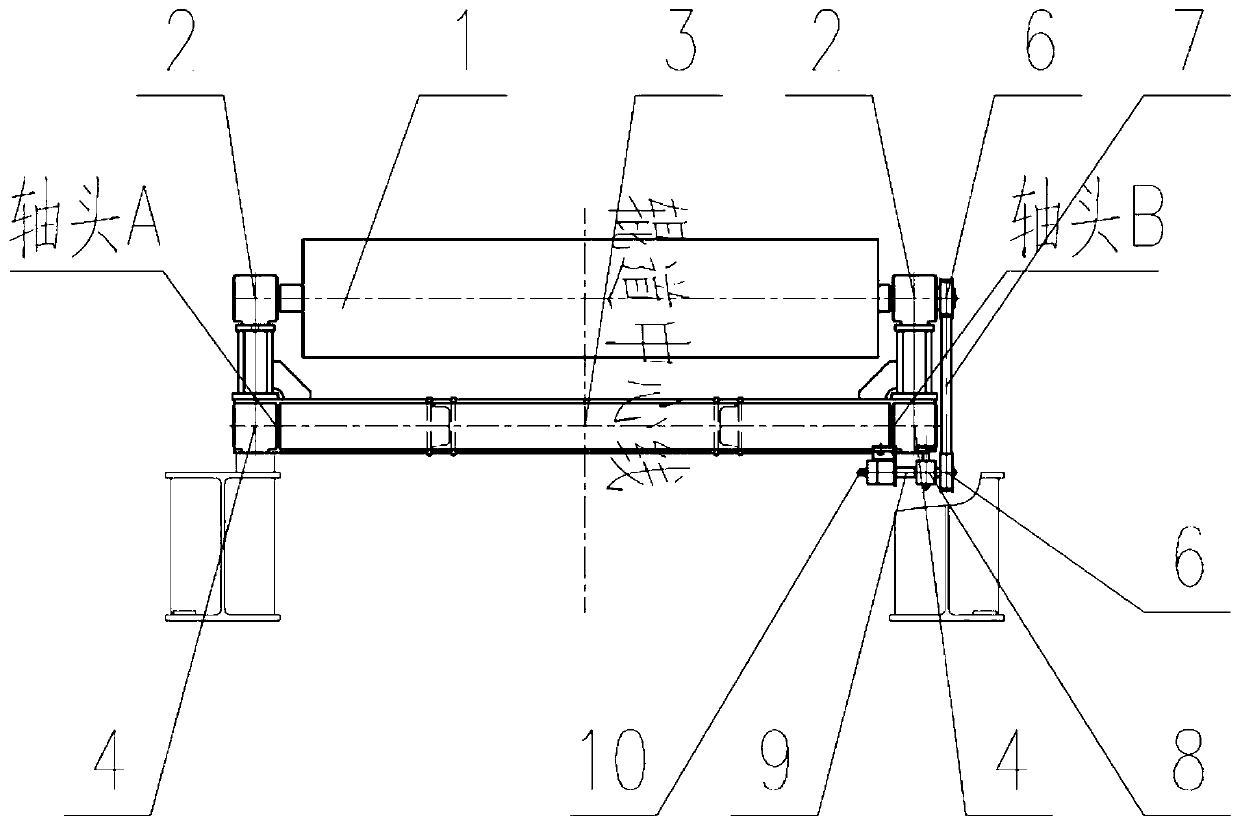

[0020] The two ends of the speed measuring roller 1 are respectively fixed on the bearing housings (1) 2 located on both sides of the center line of the roller table, and the bearing housings (2) 4 are arranged symmetrically along the center line of the roller table, respectively fixed on the roller table frames, and fixed on the swing frame 3 The upper shaft head A is fixed on the bearing seat (2) 4 on the left side of the center line of the roller table, and the shaft head B is fixed on the bearing seat (2) 4 on the right side of the center line of the roller table on the swing frame 3. figure 2 shown.

[0021] The encoder 10 assembly includes a toothed belt wheel 6, a toothed belt 7, a shaft 9, a bracket 8, and an encod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com