Stress resistance effect measuring method for material in high strain rate state

A technology with high strain rate and measurement method, which is applied in the measurement, measurement device, measurement of electrical variables, etc. of the property force of piezoelectric resistance materials, which can solve the problems of complicated operation and human error, and achieve the effect of accurate measurement data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

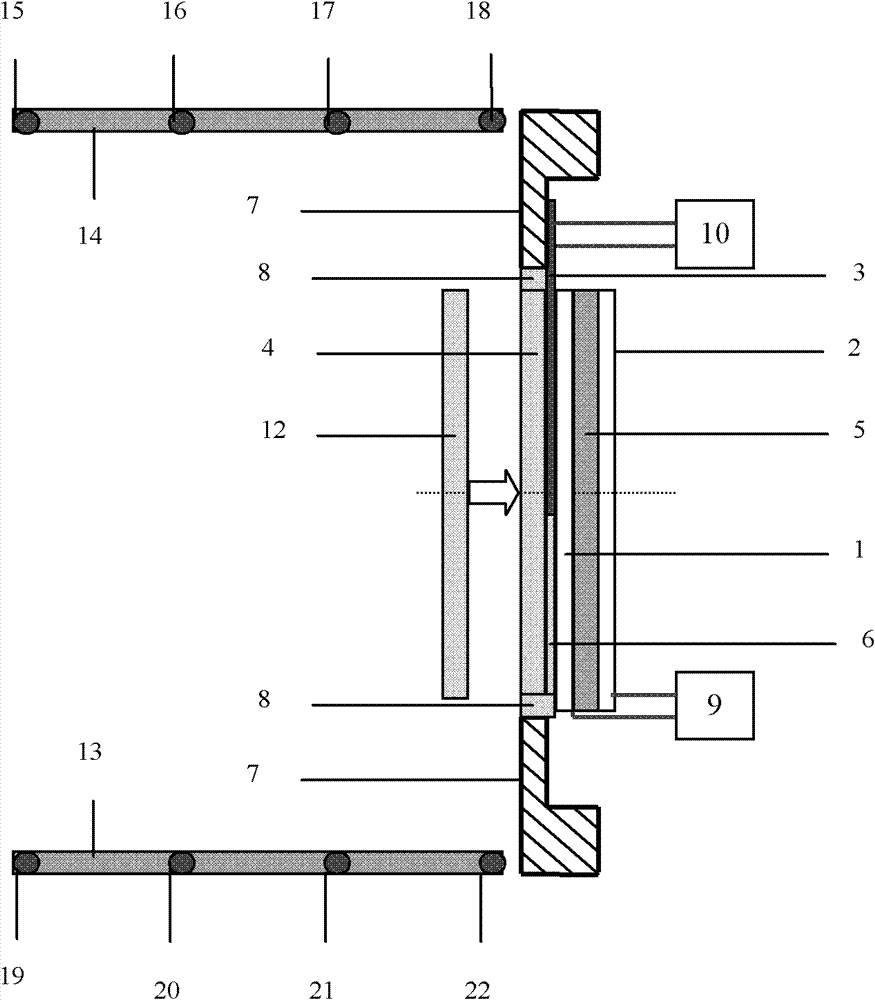

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0019] A method for measuring the force resistance effect of a material in a high strain rate state, the specific steps are as follows:

[0020] Step 1: first apply the pure silver conductive paint evenly and flatly on both surfaces of the tested material 5 to form the first pure silver conductive paint layer 1 and the second pure silver conductive paint layer 2, and wait for drying;

[0021] Step 2: Fix the manganin gauge force sensor 3 on the gasket 4 with glue, then put the first pure silver conductive paint layer 1 on the tested material 5 against the gasket 4, and glue the gasket 4 with glue 6 The gap between the first pure silver conductive paint layer 1 is filled;

[0022] Step 3: Select four insulating varnish copper wires with a diameter of 0.2 mm to 0.4 mm, which are respectively the first wire, the second wire, the third wire and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com